Self-adjusting constant-micro-resistance check valve

A check valve, self-adjusting technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve the problems of low energy consumption, energy consumption, and inability to achieve micro-resistance, and achieve the effect of meeting the requirements of national standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

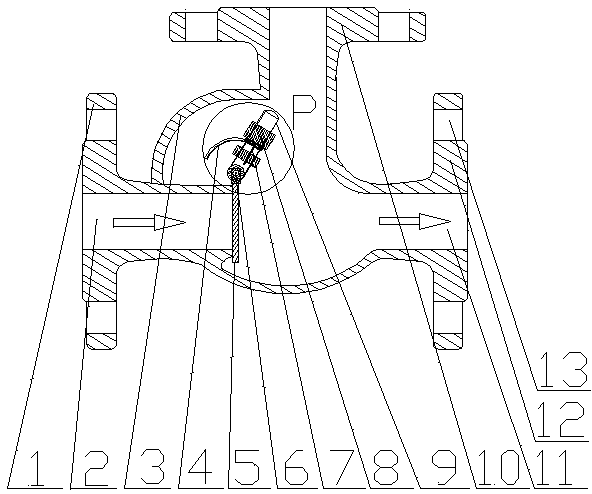

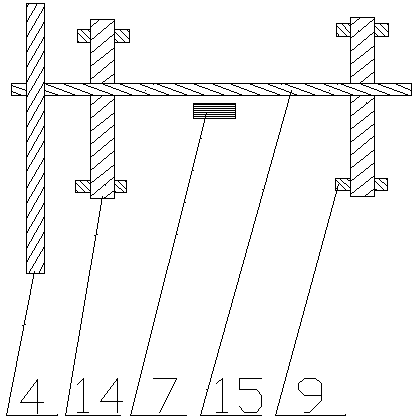

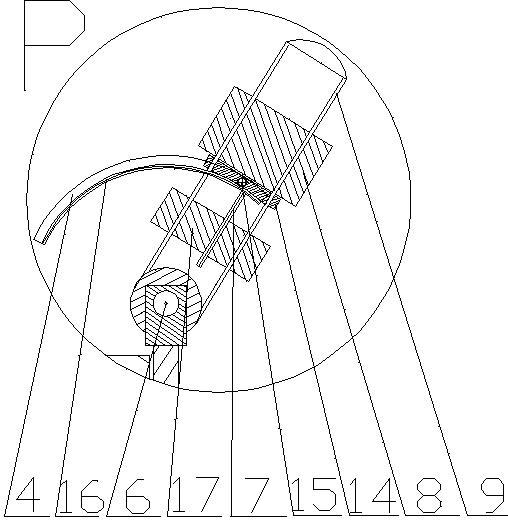

[0023] exist figure 1 In the embodiment of the horizontally installed check valve shown in -7: the self-adjusting constant micro-resistance check valve includes a valve core plate rotating shaft 6 installed in the valve body 3, which can be sealed with the valve inlet 2 sealing ring and installed in the valve body. The spool plate 5 that rotates to open and close in the body 3, and the spool plate 5 counterweight bracket 9 that is connected to the 6 ends of the spool plate rotating shaft and forms a certain angle with the spool plate 5, is installed on the spool plate 5 counterweight The upper counterweight 8 on the support 9 and the lower counterweight 17, the rotating shaft 15 between the counterweights installed between the upper and lower counterweights, the shaft 15 installed on the lower side of the upper counterweight 8 and between the counterweights The moving straight rail 7 meshing with the center teeth of the rotating shaft 15, and the arc rack 4 meshing with the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com