Sintering system and sintering endpoint control method thereof

A control method and sintering end point technology, applied in the furnace type, furnace, lighting and heating equipment, etc., can solve the problems of poor accuracy, affecting sintering quality, low efficiency, etc., and achieve the effect of accurate judgment and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

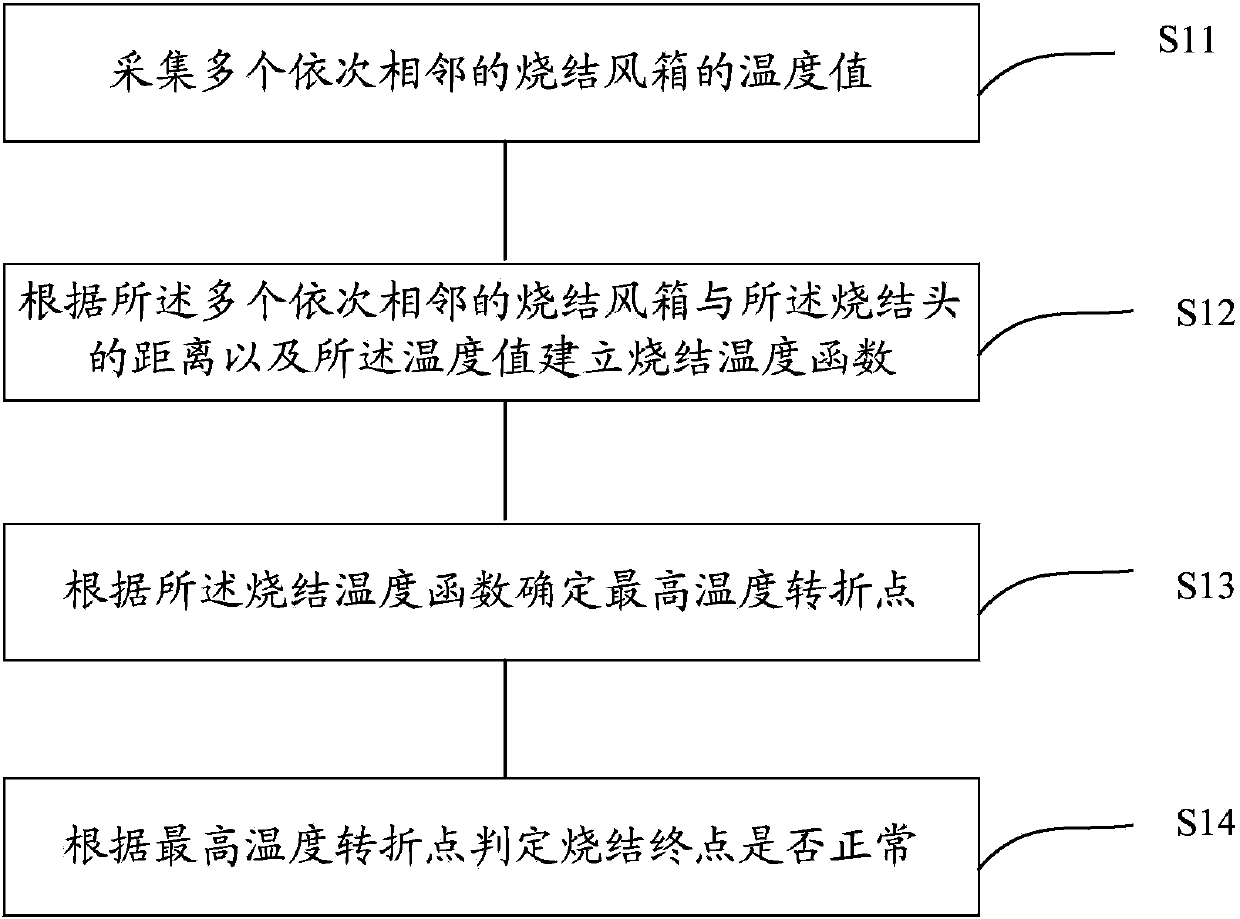

Method used

Image

Examples

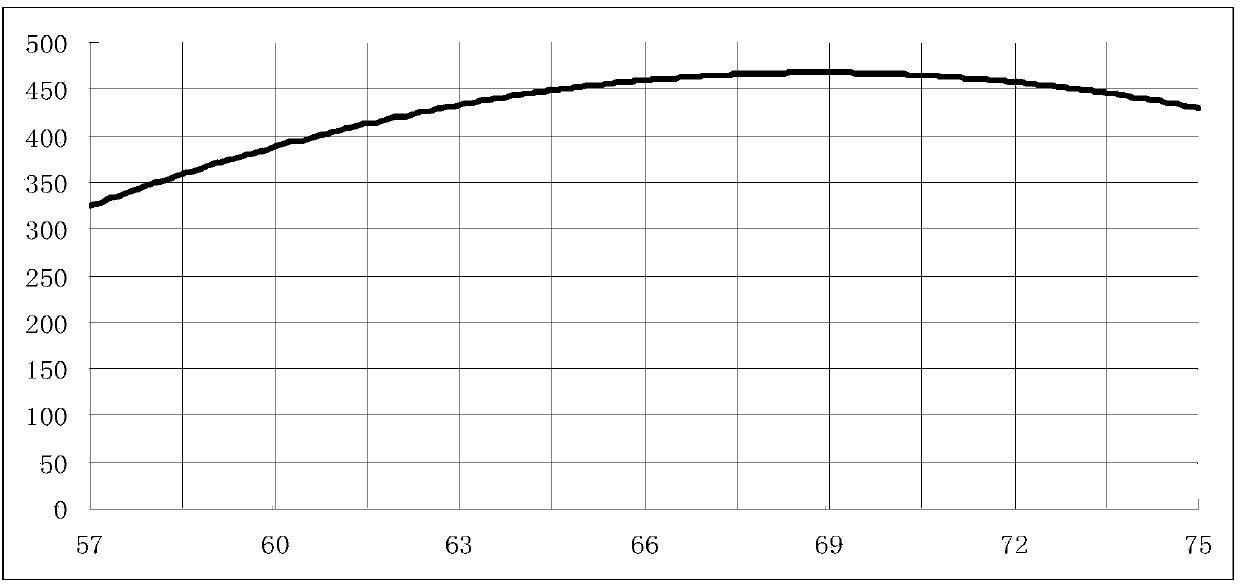

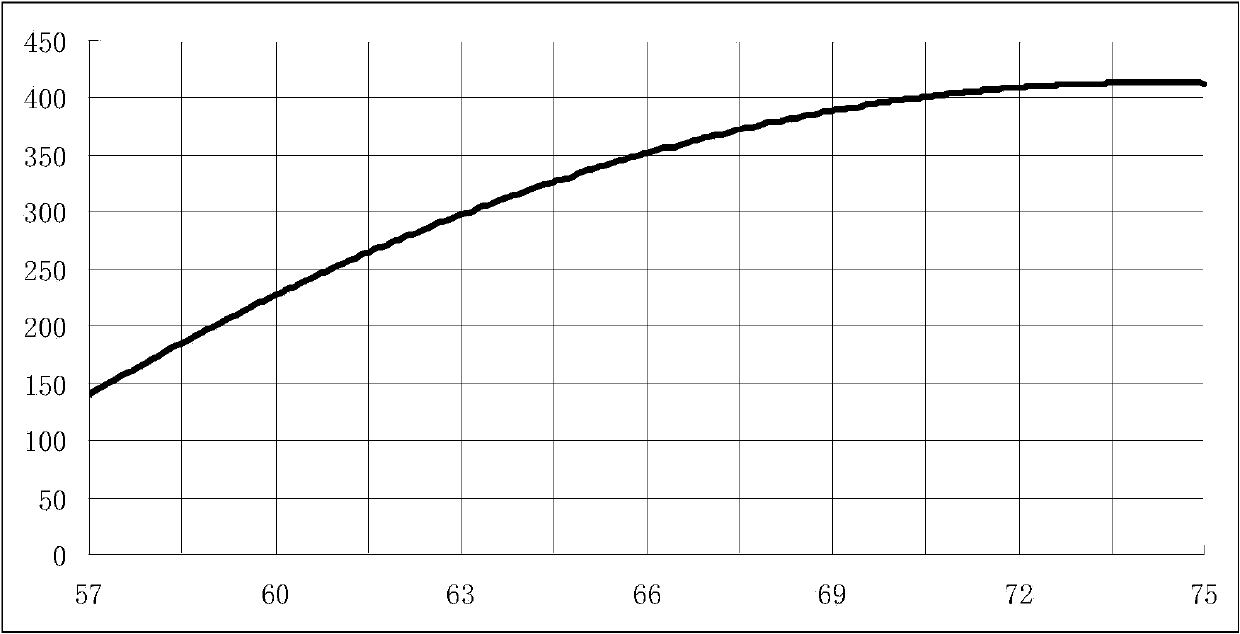

Embodiment Construction

[0040] As mentioned in the background technology, at present, in the sintering production of enterprises, it is often controlled by manual experience. Watching the section of the tailings layer from the scene or online video, there is no flame coming out, and the upper black and lower red ore layers account for about 2 / 3 and 1 / 3 respectively. 3. It can be judged that the end point is normal; if the black layer becomes thicker and the red ore layer becomes thinner, it can be judged that the end point is advanced; if there are flames at the lower edge of the red layer, and there are unburnt raw materials, it can be judged that the end point is delayed. If the end point is found to be early, the speed of the machine should be increased; if the end point is lagging behind, the speed of the machine should be slowed down; when the air permeability has changed greatly and it is difficult to control the end point only by adjusting the speed of the machine, the thickness of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com