Mould for testing aerodynamic configuration of repaired wind turbine blade, mould manufacture method and testing method through mould

A technology for inspecting molds and wind rotor blades, applied in mechanical counters/curvature measurement, etc., can solve problems such as increasing operating costs, difficult to use wind rotor blades, and inability to transport vehicles, so as to reduce repair costs and improve repair efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, and are described in detail as follows:

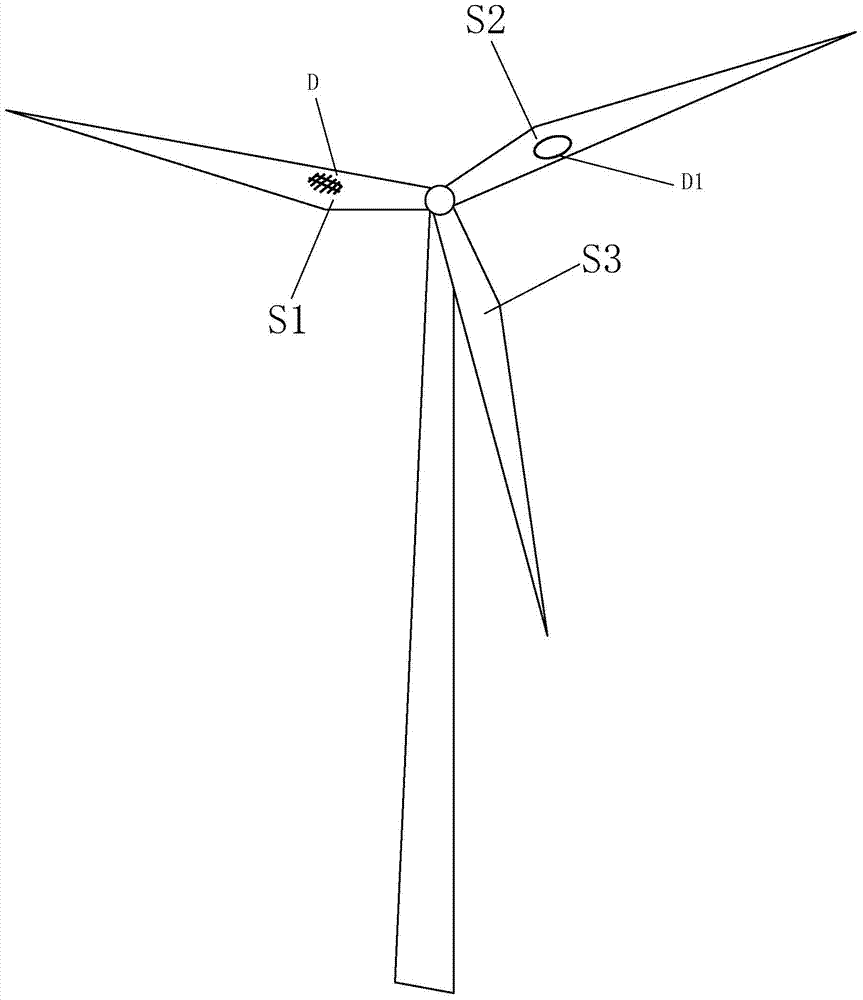

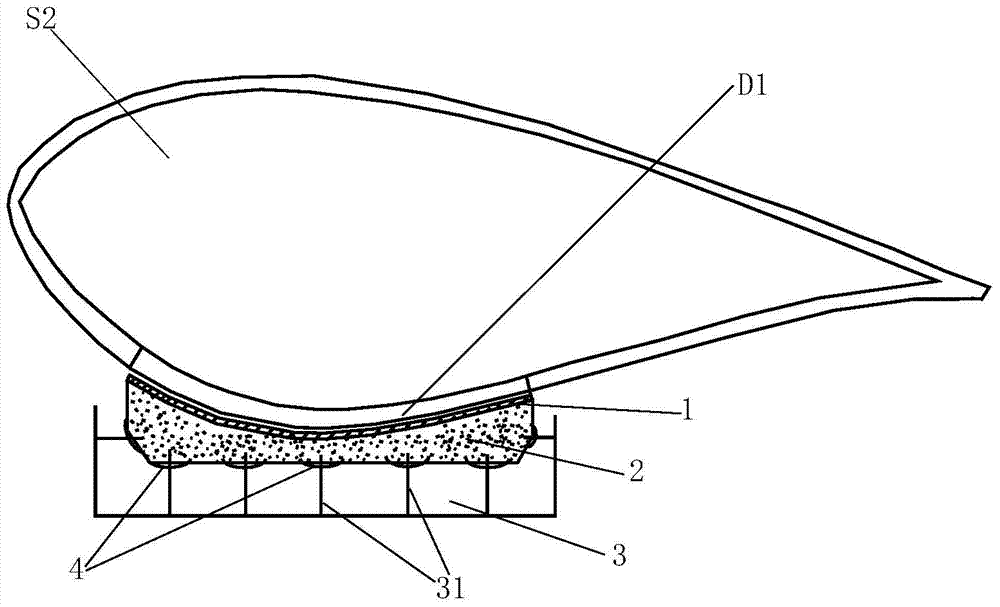

[0042] Such as figure 1 As shown, the wind turbine has three blades S1, S2, S3. When the blade S1 has a damaged part, at least one of S2 and S3 is intact, assuming that the blade S2 is intact (integrity refers to maintaining the aerodynamic shape of the original design). If the damaged part D of the blade S1 occurs on the windward side of the blade S1, and the spanwise distance from the root of the blade is 20 meters, and the distance from the leading edge of the blade is 2 meters in the chord direction, according to this, the above-mentioned The position parameter finds the corresponding position D1 corresponding to the damaged part D of S1. At this time, circle D1 with a line and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com