A device for measuring the equivalent wall thickness of scaffolding steel pipes and its measuring method

A technology of wall thickness measurement and scaffolding, applied in the direction of measuring devices, instruments, etc., can solve the problems of high construction requirements, low accuracy rate, inapplicability, etc., and achieve the effect of accurate and reliable measurement results, high solution cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

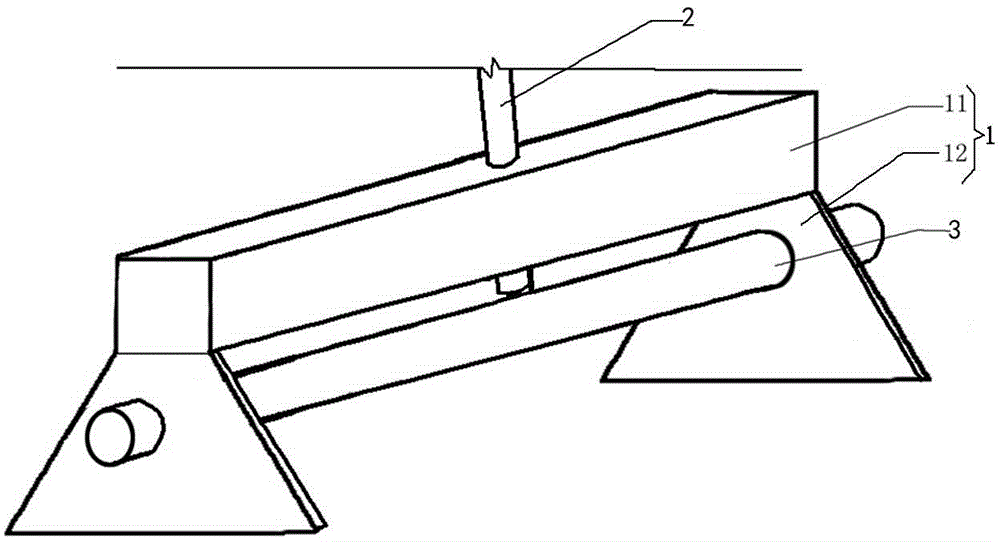

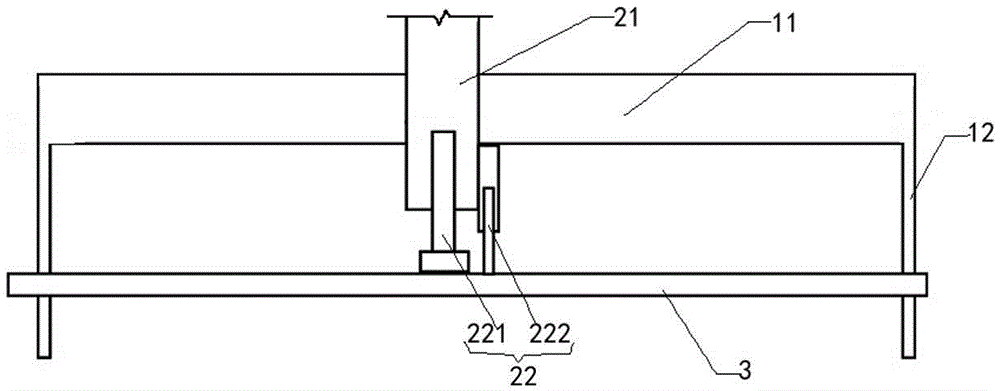

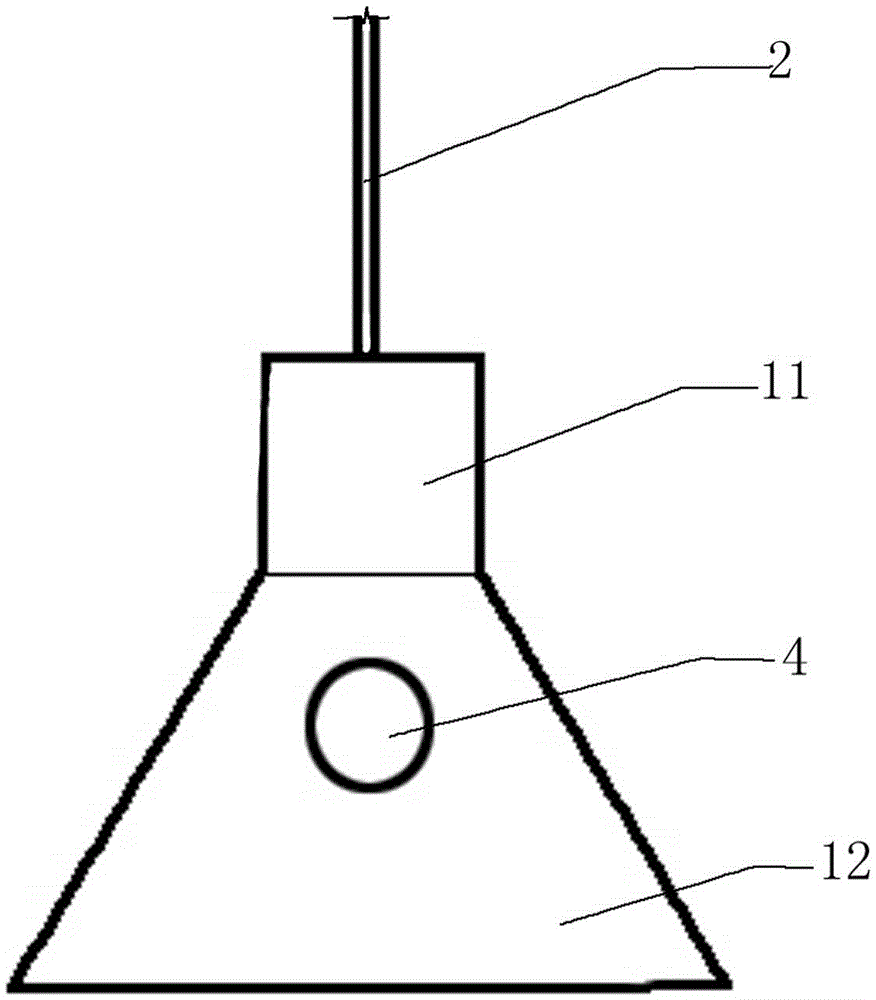

[0024] Such as Figure 1~3 As shown, a scaffold steel pipe equivalent wall thickness measuring device, including a simply supported steel frame 1 supporting the scaffold steel pipe to be measured and a loading detection component 2 connected to the simply supported steel frame 1, is characterized in that: the simply supported steel The main body of the frame 1 is a horizontal supporting steel beam 11, and each side of the supporting steel beam 11 is connected with a vertical supporting ear plate 12 perpendicular to the supporting steel beam; the plate surface of the supporting ear plate 12 Correspondingly, there is a scaffold steel pipe reserved opening 4, and the scaffold steel pipe 3 to be tested is cross-armed in the middle of the simply supported steel frame through the scaffold steel pipe reserved opening 4 on both sides; the loading detection part 2 includes sequentially connected loading Unit 21, sensor 22, data collector 23, data processing unit 24 and result output un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com