A slip detection device and slip control method for a high-voltage line inspection robot

A technology for inspection robots and high-voltage lines, which is applied in the direction of overhead lines/cable equipment, manipulators, manufacturing tools, etc., can solve the problems of small pressing force, low control efficiency, and over-tightening, so as to prevent over-tightening, The effect of prolonging the service life and strengthening the line capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

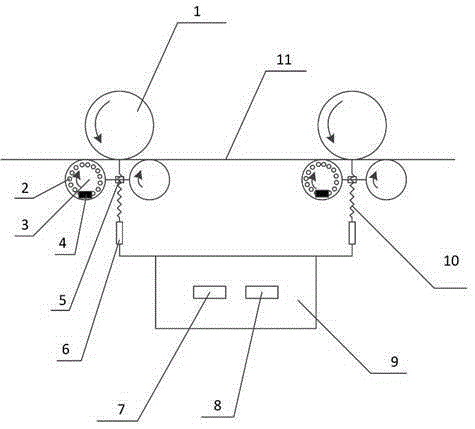

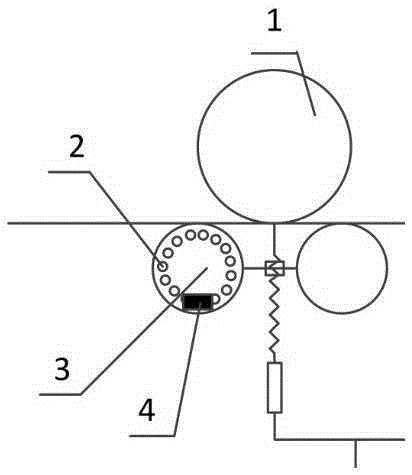

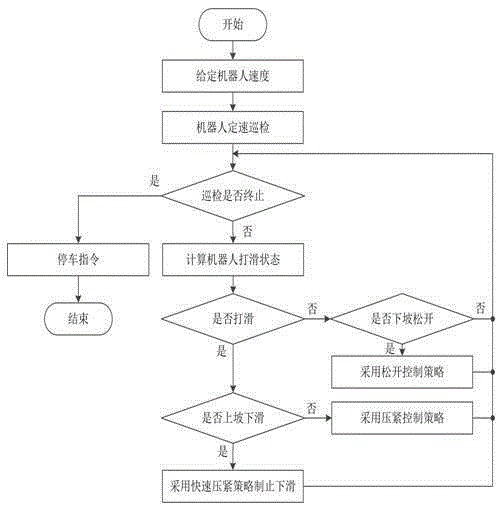

[0036] please see figure 1 , figure 2 , the technical solution adopted by the device of the present invention is: a slip detection device of a high-voltage line inspection robot, which is installed on a high-voltage line inspection robot, including a pair of pressing wheels 3, a circular array magnetic steel 2, a Hall sensor 4. An inclination sensor 7 and an acceleration sensor 8; a pair of pinch wheels 3 are symmetrically arranged on the pinch wheel bracket 5 of the inspection robot, close to the wire 11 and opposite to the walking wheel 1 of the inspection robot up and down; The array magnetic steel 2 is embedded in the side of the pinch wheel 3, and the side of the circumferential array magnet 2 is flush with the side of the pinch wheel 3; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com