A composite diaphragm type flat-panel earphone

A diaphragm-type, flat-panel technology, applied in earpiece/headphone accessories, etc., can solve the problems of difficult sound characteristics, uneconomical, R&D costs and long R&D cycle, and achieve good sound effects, high-frequency response and transient balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail, so that those skilled in the art understand:

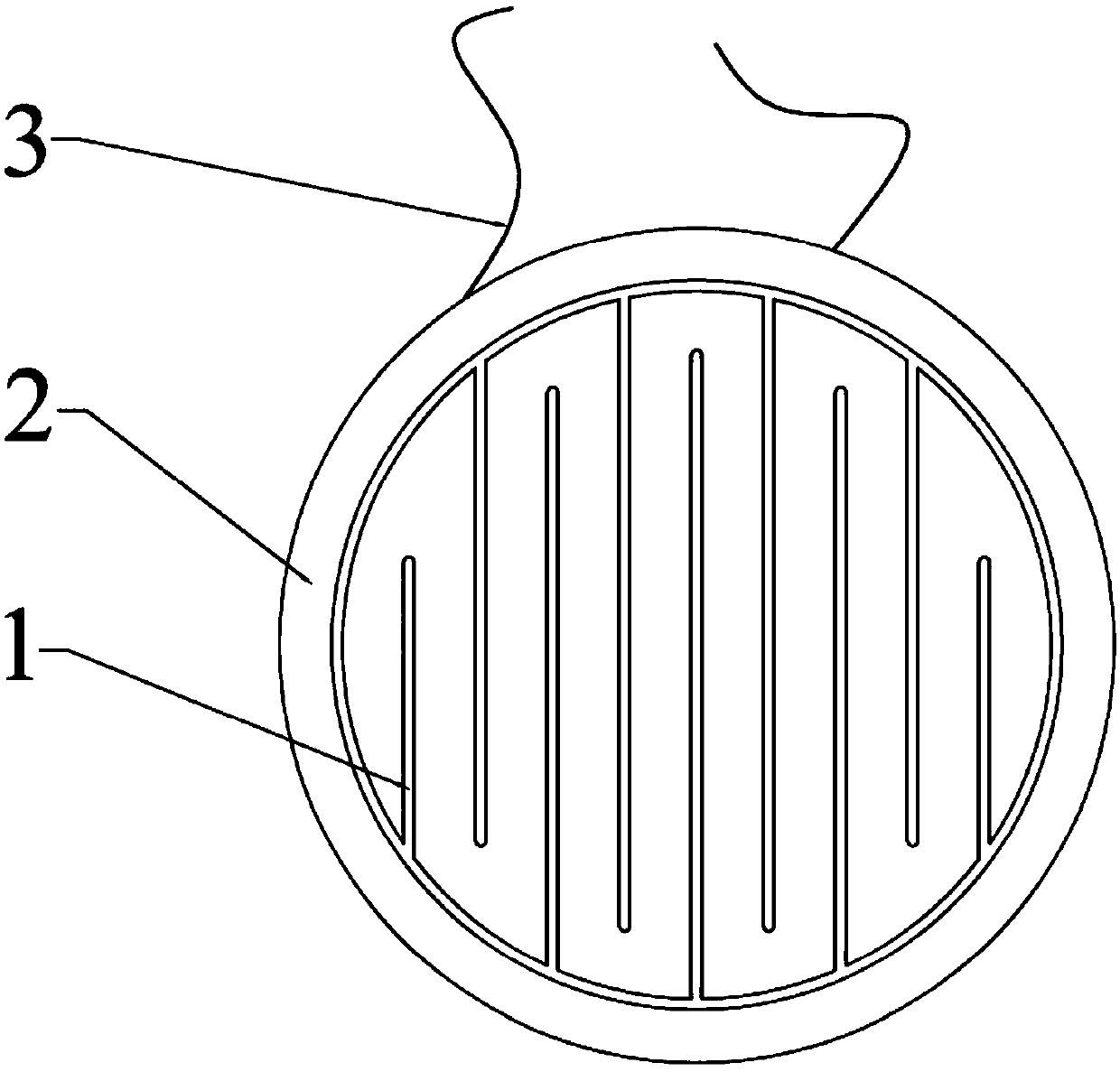

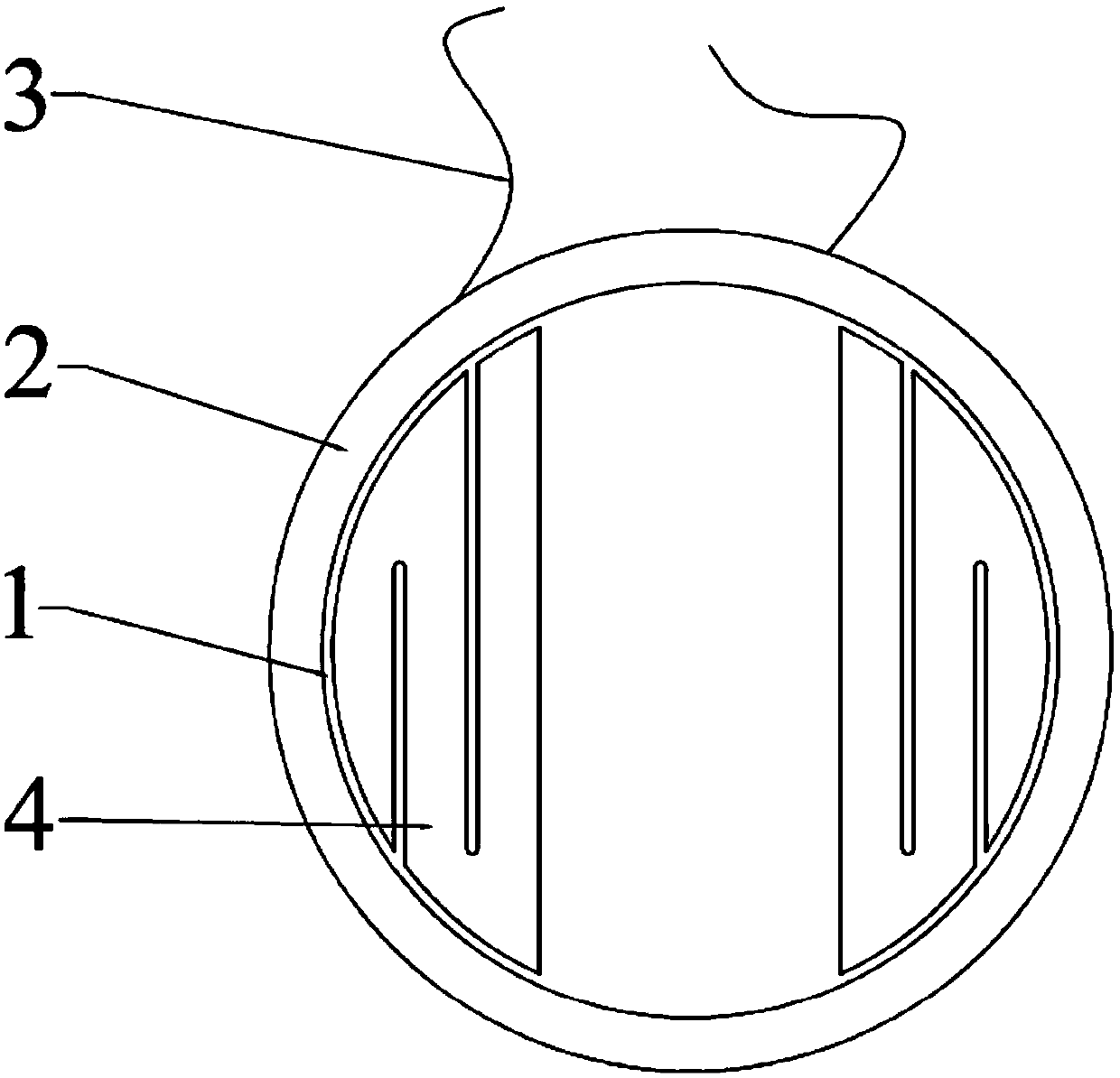

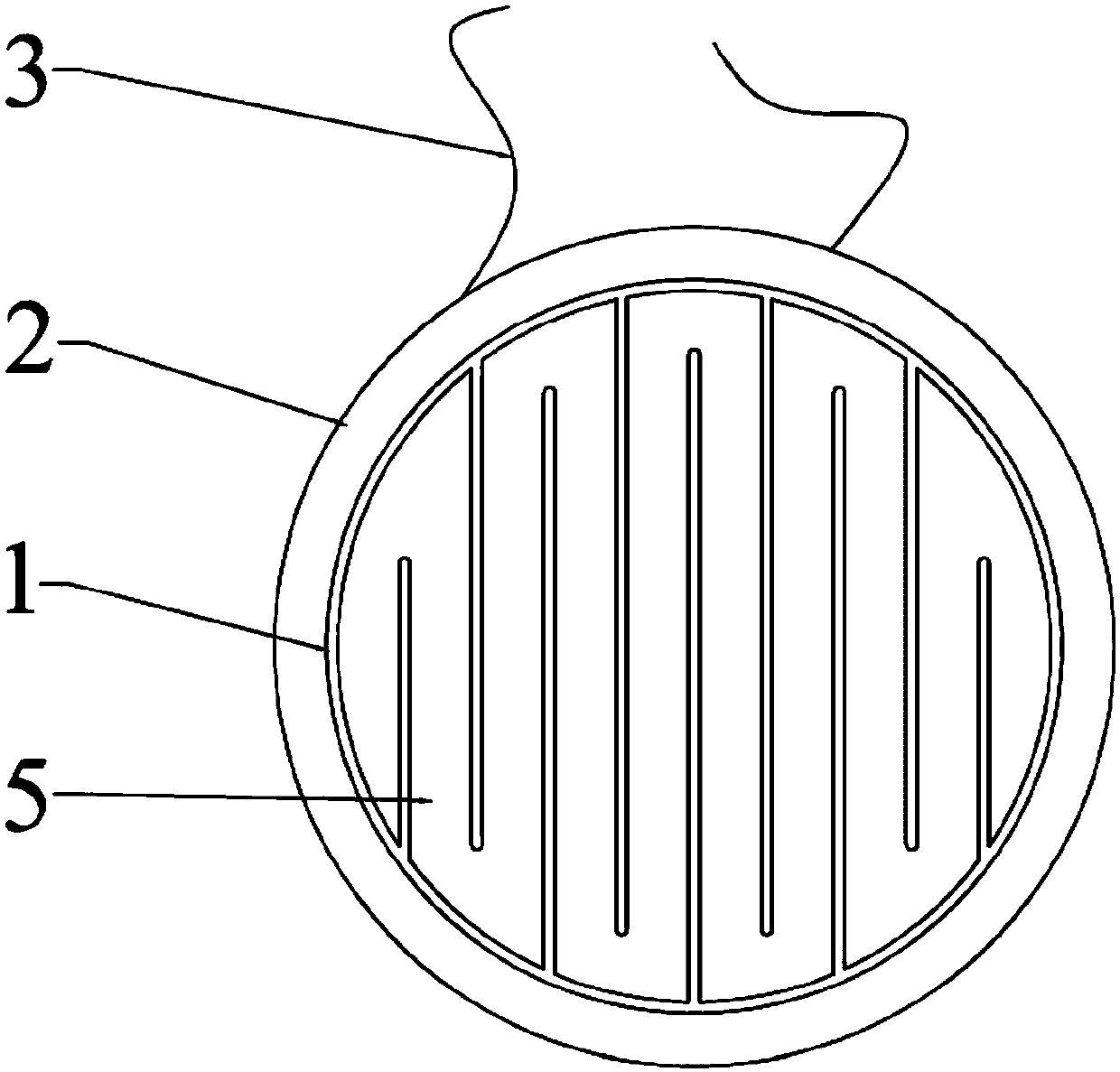

[0026] Such as Figure 1-4 As shown, the labels represent:

[0027] Diaphragm 1, frame 2, wire 3, first sub-coil 4, second sub-coil 5, headband 6, left earmuff 7, right earmuff 8.

[0028] see Figure 2-4 As shown, the present embodiment 1 first proposes a composite diaphragm type planar earphone. The planar earphone has a headband 6, a left earmuff 7 and a right earmuff 8 arranged at both ends of the headband 6, and a flat panel placed in the left and right earmuffs. type transducer. The structure of the planar transducer is the same as that of the conventional planar transducer, including a diaphragm 1 fixed on the frame 2 and a permanent magnet opposite to the coil on the diaphragm 1 . The permanent magnets can be arranged on both sides of the diaphragm 1 (push-pull type) or only on one side (unipolar type). Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com