Stacking-type full-height centrum forming device

A vertebroplasty and superimposed technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of unfavorable kyphosis recovery and other problems, to avoid loss of vertebral body height, easy to popularize and use, reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

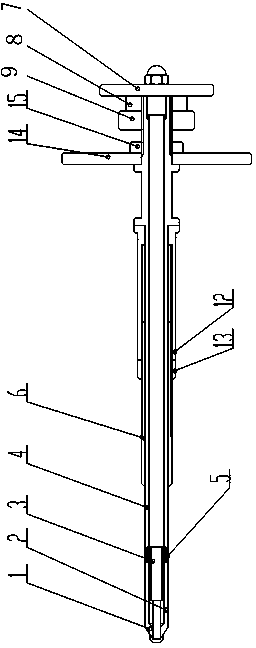

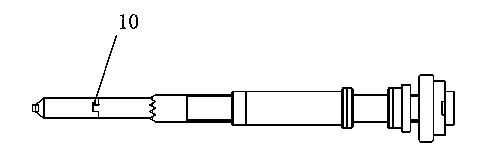

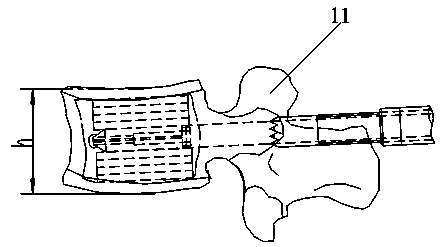

[0021] Such as Figure 1~3 The superimposed full-height vertebral body 11 shaper shown includes a superimposed implant component, which is connected with an instrument part component, and its difference lies in that the superimposed implant used in the present invention Incoming components include overlay components. At the same time, the instrument part assembly includes an internal fixation rod 3, and the internal fixation rod 3 is connected to the superimposed sheet assembly. Specifically, an outer conduit 4 is arranged on the outside of the inner fixing rod 3 , and a handle assembly 5 is arranged at the front section of the outer conduit 4 , and the handle assembly 5 is in contact with the superimposed sheet assembly. In addition, a guiding and fixing pipe 6 is arranged on the outer periphery of the middle section of the outer catheter 4 , and an adjustment assembly is connected to the guiding and fixing pipe 6 , and a separating assembly is arranged at the tail section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com