Blade Tensioning Structure of Thermal Cutting Device for Plastic Profiles

A cutting device and blade technology, which is applied in metal processing and other directions, can solve the problems of different sizes of profile sections, uneven cutting sections of profiles, bending and deformation of blades, etc., to achieve regular cutting sections, not easy to break and damage, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

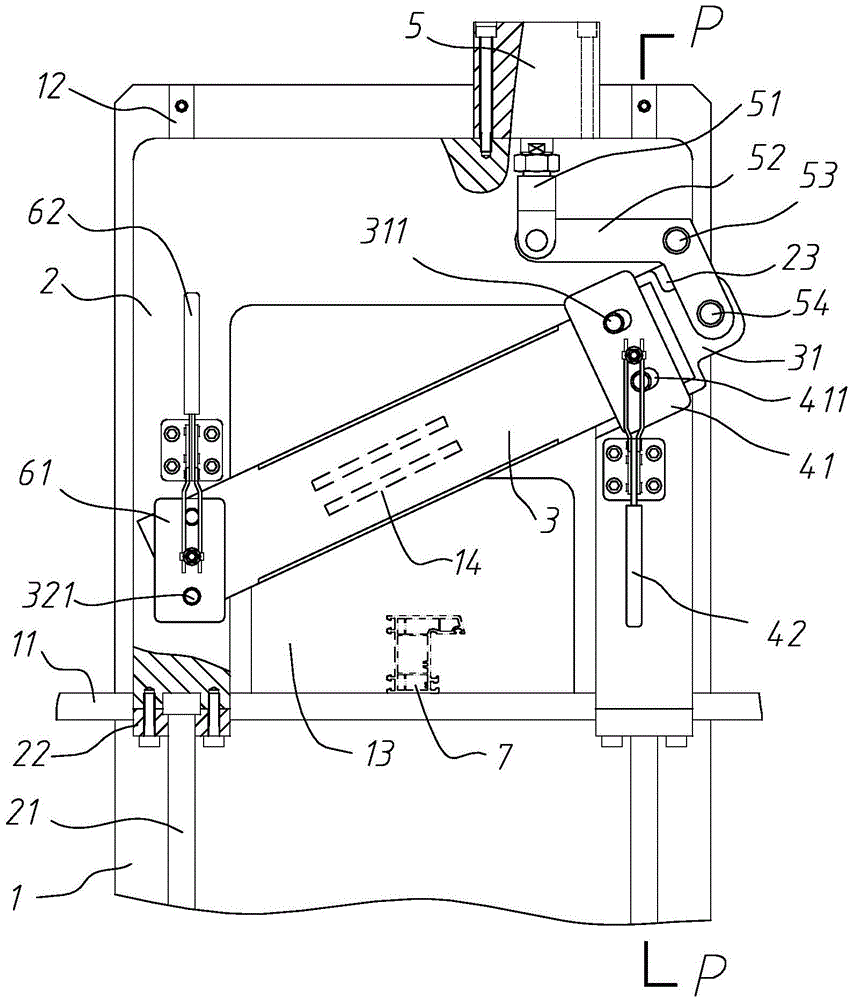

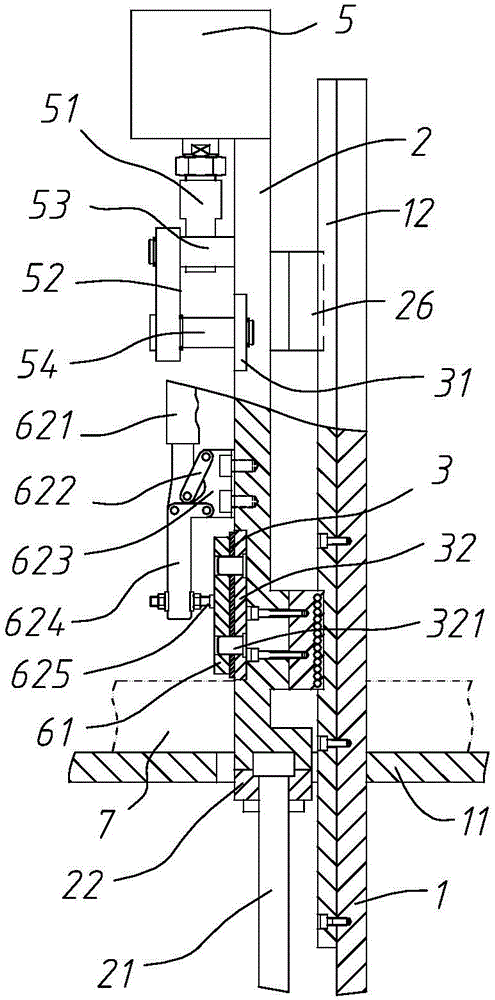

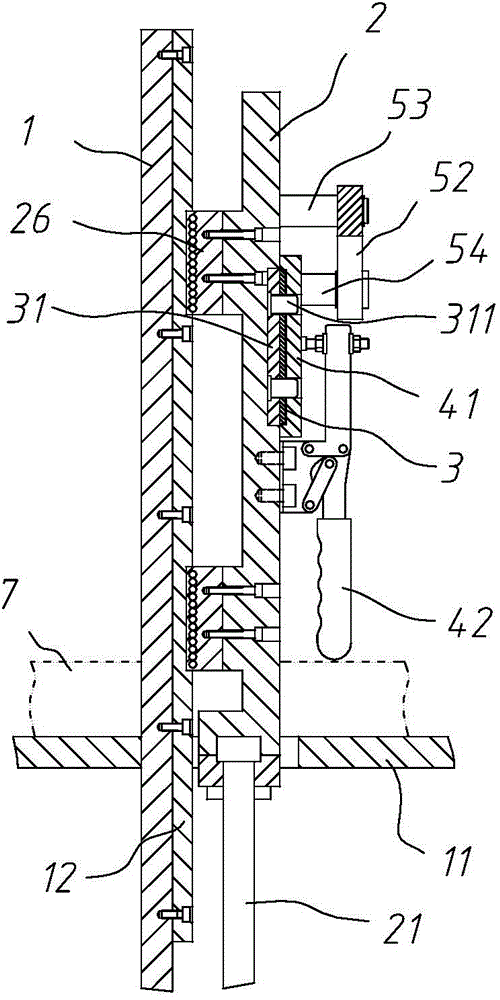

[0015] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a frame 1 , a tool holder 2 and a blade 3 . The frame 1 is a vertical base plate, and the middle part of the frame 1 is provided with a horizontal base plate 11 as a workbench, and in the middle of the frame 1 above the horizontal base plate 11, there is a hole 13 for the profile 7 to be cut to pass. The tool holder 2 is in the shape of an inverted U. Linear guide rails 12 are provided on both sides of the frame 1. Sliders 26 cooperating with the linear guide rails 12 are fixed on both sides of the tool holder 2. The tool holder 2 can be raised and lowered through the cooperation of the sliders 26 and the linear guide rails 12. fixed on rack 1. The electric heating device 14 that heats the blade 3 fixed on the knife holder 2 is housed on the frame 1 . A pair of pull rods 21 are respectively fixed on both sides of the lower end of the knife rest 2 by a gland 22, and the lower ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com