Solid state fermentation control method based on neural network and particle swarm algorithm

A particle swarm algorithm and neural network technology, applied in the field of bioengineering equipment, can solve the problems of low solid-state fermentation production efficiency, pollution, and inability to detect the temperature, humidity, pH physical parameters of solid materials in real time online, etc., to improve production efficiency, Avoid contamination, control process reliably and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

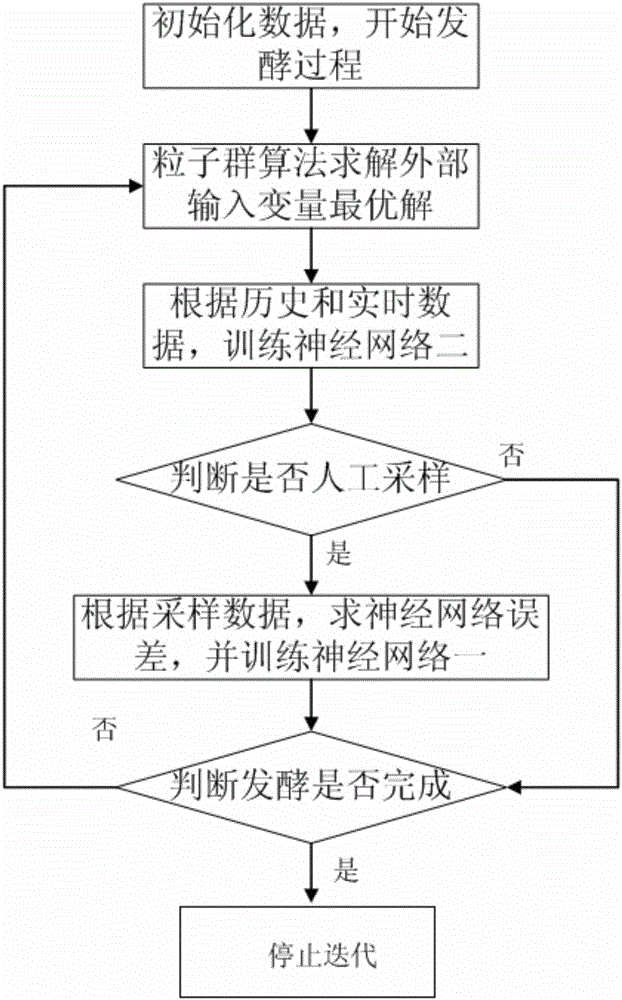

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

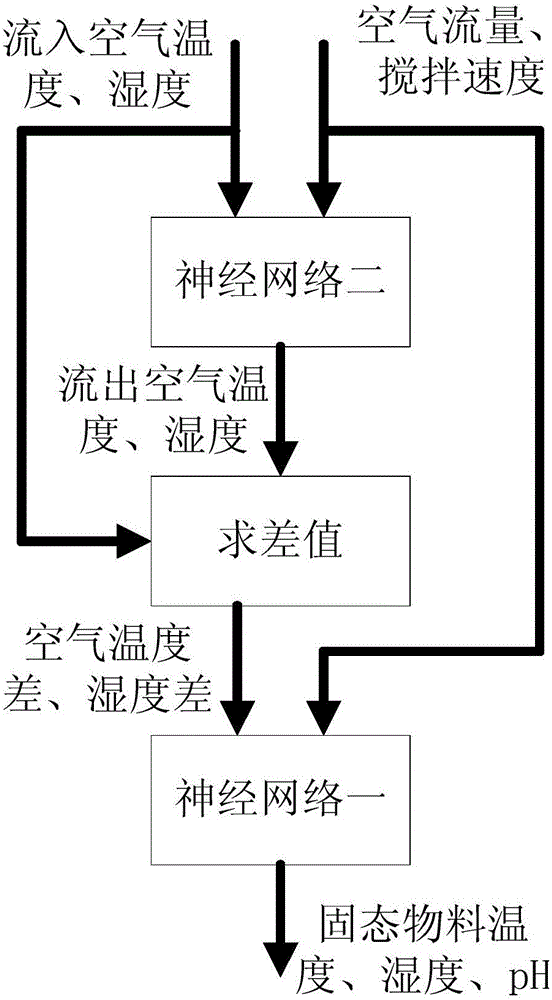

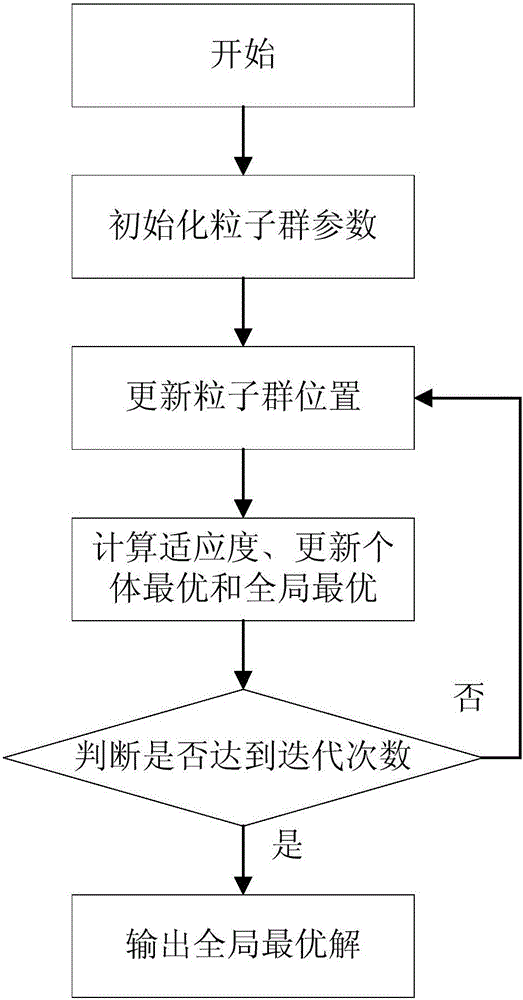

[0033] During the solid-state fermentation process, the air flow rate, the temperature and humidity of the air flowing into the fermentation equipment, and the temperature and humidity of the air flowing out of the fermentation equipment can be measured in real time, but the three physical quantities of the temperature, humidity, and pH value of the solid material are difficult to measure and are accurate. The fermentation problem is very important. The present invention first uses a neural network to establish the mapping relationship between the temperature difference, humidity difference, air flow rate, stirring rate and the temperature, humidity and pH value of the solid-state fermentation material, and then uses Another neural network establishes the mapping relationship between the flow rate, temperature, humidity, stirring speed of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com