Laminated plate type spreading mechanism

A spreading mechanism and laminated plate technology, which is applied to roads, road repairs, roads, etc., can solve the problems of easy blockage of nozzles, increased construction costs, and heavy maintenance workload, achieving large coverage, good spreading uniformity, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

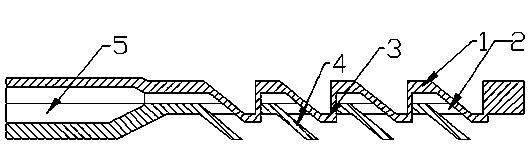

[0015] Further description will be given below in conjunction with the accompanying drawings

[0016] like figure 1 As shown, a laminated plate spreading mechanism, the spreading mechanism includes two structural plates A2 and structural plate B1 that are attached to each other, and the spreading mechanism is provided with a semi-closed through hole formed by the inner concave surface of the structural plate A2 and the structural plate B1;

[0017] The structural plate A2 is provided with a number of deflectors 4 which are formed by the structural plate A2 being turned outward, and the structural plate B1 is provided with a number of inner concave surfaces 3 corresponding to the position of the structural plate A2;

[0018] The inner concave surface 3 and the deflector plate 4 folded outward form the asphalt flow guide channel;

[0019] The open end of the semi-closed through hole is circular, and the open end is connected with an asphalt feed pipe.

[0020] A sealing rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com