A prestressed anchor rod preventing pulling out from the anchor hole

A technology of prestressing and bolting, which is applied in the direction of installing bolts, sheet pile walls, mining equipment, etc., and can solve the problem of not being able to adapt to the immediate support of weak rock and soil, restricting the application and development of rock and soil anchoring technology, and the inability of grouting Provide anchoring force and other issues to achieve the effect of improving the load transfer mechanism, optimizing the load transfer mechanism, and improving the effect of rock and soil reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

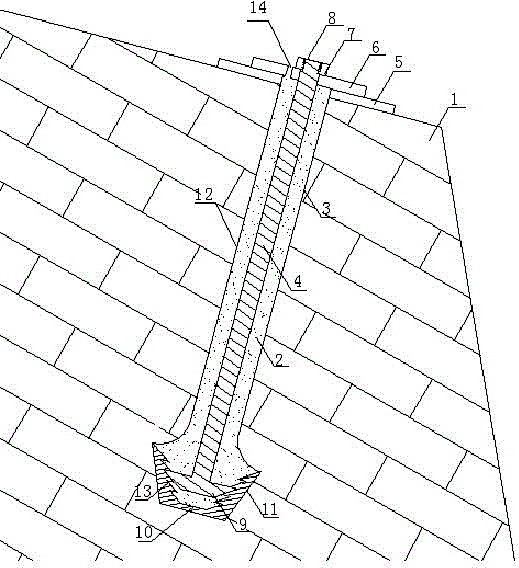

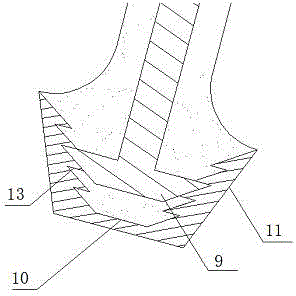

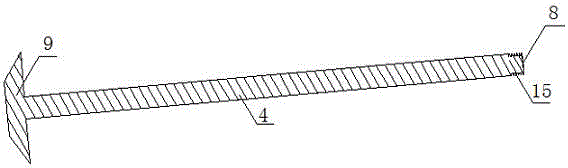

[0027] Such as Figure 1~7 As shown, a prestressed anchor rod that prevents being pulled out from the anchor hole includes an anchor rod body 4 with an expansion plug 9 at the bottom, an expansion tooth bowl 10, a base 5, a backing plate 6, and a nut 7. Both the base 5 and the base 6 are provided with anchor holes; the top 8 of the anchor body 4 passes through the anchor holes of the base 5 and the base 6 in turn and is connected with the nut 7; the expansion plug 9 is placed on the expansion gear Inside the bowl 10.

[0028] Wherein: the expansion plug 9 is in the shape of a truncated cone.

[0029] Threads 15 are provided on the top 8 of the anchor rod body 4 .

[0030] The expansion tooth bowl 10 is in the shape of a bowl with a large mouth and a small bottom. The inner surface coincides with the side of the expansion plug 9.

[0031] A grouting hole 14 is opened on the backing plate 6 .

[0032] During use, (1) drill hole 3 to rock and soil body 1 according to the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com