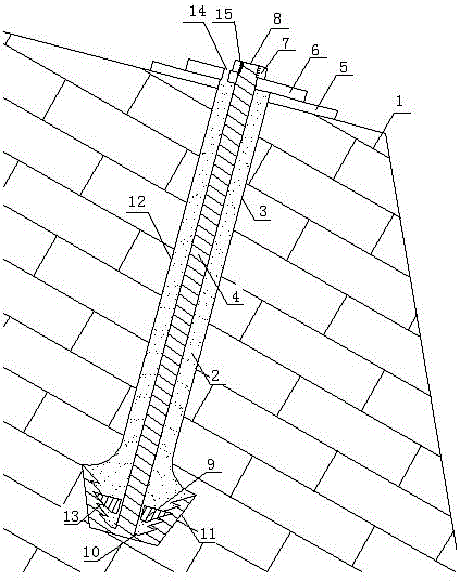

Prestressed anchor rod to prevent pulling out of the anchor hole

A prestressed and smooth technology, which is applied in the direction of installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problem of not being able to adapt to the immediate support of weak rock and soil, restricting the application and development of rock and soil anchoring technology, and the grouting body cannot provide Anchor force and other issues to achieve the effect of optimizing the load transfer mechanism and improving the load transfer mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

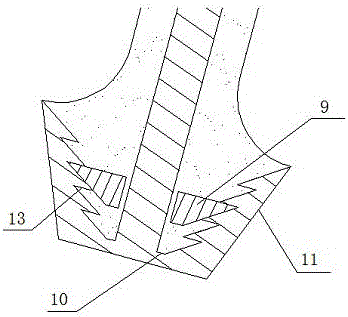

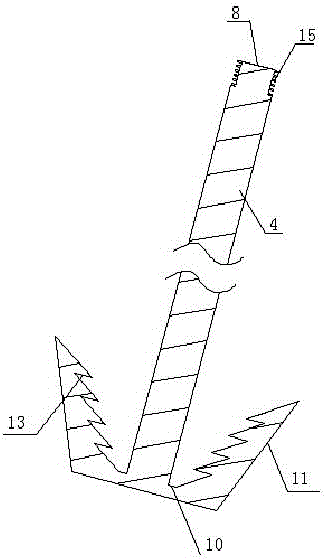

[0032] Example 1 (1) According to the design requirements, the rock and soil body 1 is drilled with the borehole 3, and the construction of the pad 5 is carried out at the mouth of the borehole 3; (2) The top of the anchor rod body 4 is passed through the expansion plug 9 with the central hole 16 of the expansion plug until Push the expansion plug 9 into the expansion tooth bowl 10 attached to the bottom end of the anchor rod body 4, so that the round table side of the expansion plug 9 coincides with the inner surface of the expansion tooth bowl 10 teeth 11; Place them together in the borehole 3 until the expansion tooth bowl 10 carried by the bottom end of the anchor rod body 4 is pushed to the bottom of the borehole 3; , apply a thrust to the round tube, and drive the frustum-shaped expansion plug 9 to the bottom of the expansion tooth bowl 10 through the round tube, and at the same time squeeze the teeth 11 of the expansion tooth bowl 10 to spread around and press into the...

Embodiment 2

[0033] Example 2 (1) According to the design requirements, the rock and soil body 1 is drilled with the borehole 3, and the construction of the pad 5 is carried out at the mouth of the borehole 3; (2) The top of the anchor rod body 4 is passed through the expansion plug 9 with the central hole 16 of the expansion plug until Push the expansion plug 9 into the expansion tooth bowl 10 attached to the bottom end of the anchor rod body 4, so that the side surface of the thin circular table of the expansion plug 9 coincides with the inner surface of the expansion tooth bowl 10 teeth 11; 4 are placed together in the borehole 3 until the expansion tooth bowl 10 carried by the bottom end of the anchor rod body 4 is pushed to the bottom of the borehole 3; 4, then add a backing plate 6 at the top 8 of the anchor rod, that is, the top 8 of the anchor rod passes through the 6 holes of the backing plate, so that the backing plate 6 is pressed on the upper end of the round pipe, and the nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com