Bead type tubular anchor rod

A technology of tubular and anchor rods, which is applied in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of inability to provide pull-out resistance, inability to adapt to weak rock and soil immediate support, and failure of rock and soil anchoring. Achieve the effects of improving the load transfer mechanism, optimizing the load transfer mechanism, and speeding up the project progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

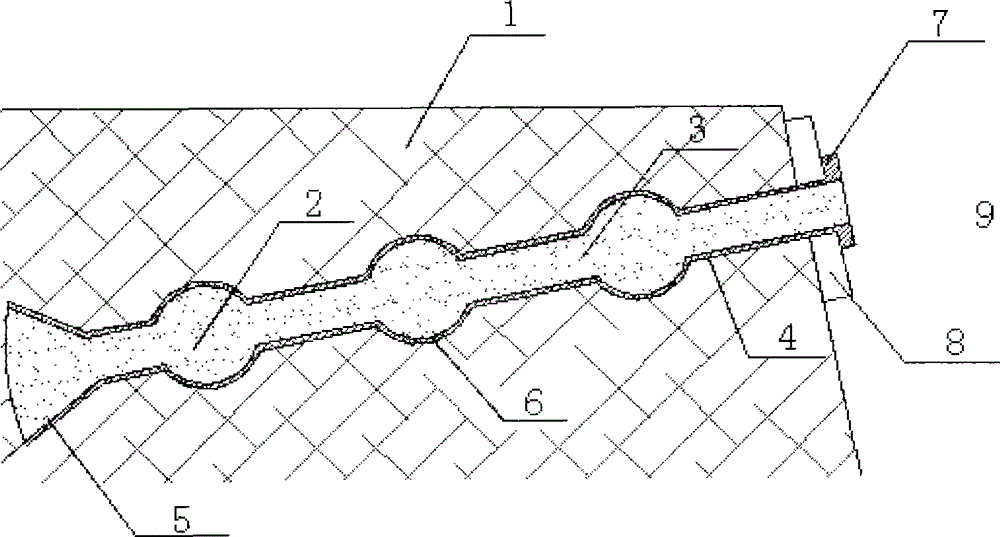

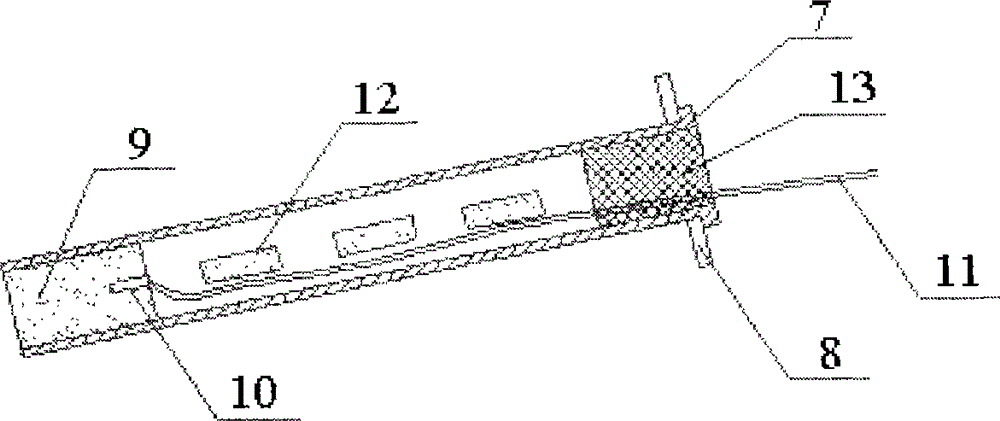

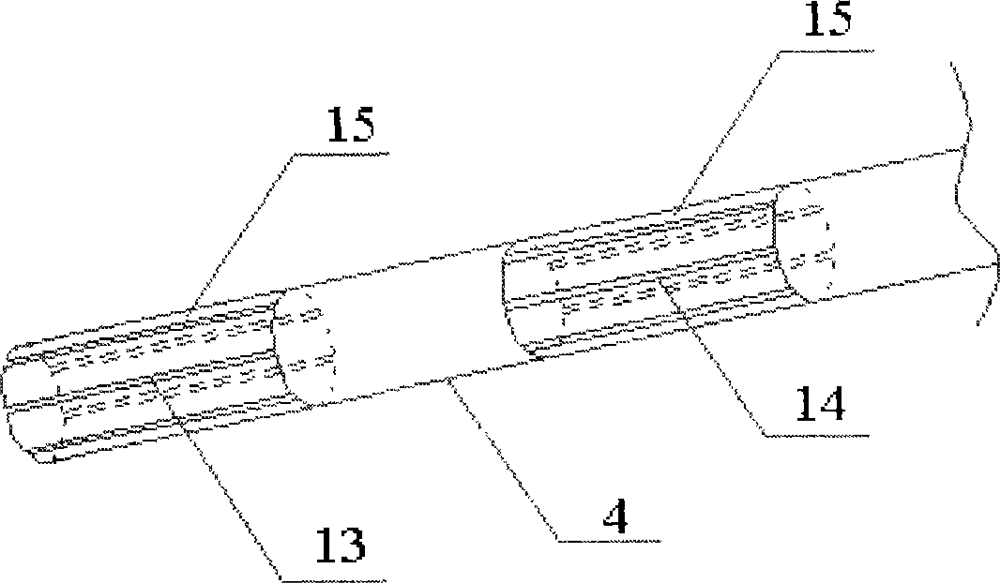

[0018] Such as Figure 1~3 As shown, the beaded tubular anchor rod includes a hollow tubular anchor rod body 4 with openings at both ends, a retaining ring 7 and a backing plate 8 . The bottom end of the tubular anchor rod body 4 is provided with axial grooves 14 penetrating the pipe wall 15 at equal intervals in the axial direction along the circumferential direction, and a retaining ring 7 with a backing plate 8 is provided at the top end thereof.

[0019] Wherein: the bottom end of the tubular anchor rod body 4 is provided with a detonator 9 with a detonator 10 inside the tube wall 15 having an axial groove 14; A cylindrical charge 12 is arranged inside the tubular wall 15 of the tubular anchor body 4 that is equally spaced axially by the axial grooves 14 .

[0020] During use, (1) carry out drilling 3 to weak rock-soil body 1 according to the design requirement; (2) insert tubular anchor rod body 4 in the borehole 3, fill the blasting mud 13 at the top of tubular anchor r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com