Automatic safe-guard chain door lock

An automatic anti-theft door lock and lock tongue technology, applied in the direction of building locks, buildings, building structures, etc., can solve the problems of easy failure, poor stability, complex structure of anti-theft door locks, etc. The structure is simple and compact, and the effect of assembly errors is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The following embodiments will be used to further illustrate the present invention in conjunction with the accompanying drawings.

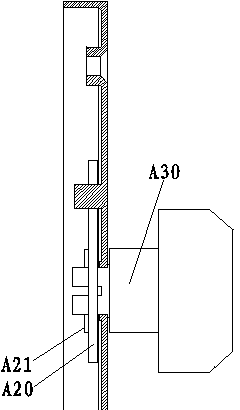

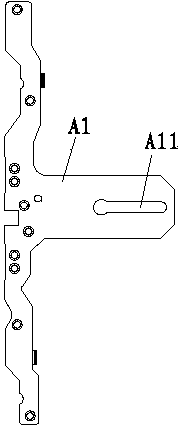

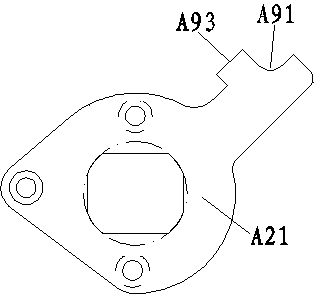

[0077] Such as Figure 1-14 As shown, the automatic anti-theft door lock described in this embodiment includes a deadbolt component installed in the lock housing, including a deadbolt assembly, and is used to install the deadbolt mounting plate A1 of the deadbolt assembly. The lock The tongue member reciprocates along the direction perpendicular to the front panel of the lock housing; the rotating device, the rotating device includes a rotating part A21, which is rotatably arranged in the lock housing, the first connecting part A22, the One end of the first connecting member A22 is hinged to the rotating member A21, and the other end is hinged to the deadbolt mounting plate A1. With the cooperation of the first guide structure that extends or retracts the deadbolt mounting plate A1, The rotating member A21 rotates through the first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com