A glass substrate lamination tool, a glass substrate end surface polishing method, and a manufacturing method of the glass substrate

A glass substrate and grinding method technology, applied in grinding devices, grinding machine tools, manufacturing tools, etc., can solve the problems of reduced roundness, reduced concentricity of glass substrates, dislocation of glass substrates, etc. Improve the effect of concentricity and roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0032] In this embodiment, the glass substrate lamination tool of this invention is demonstrated.

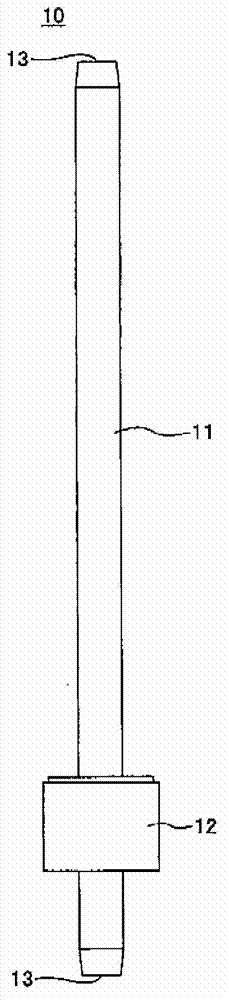

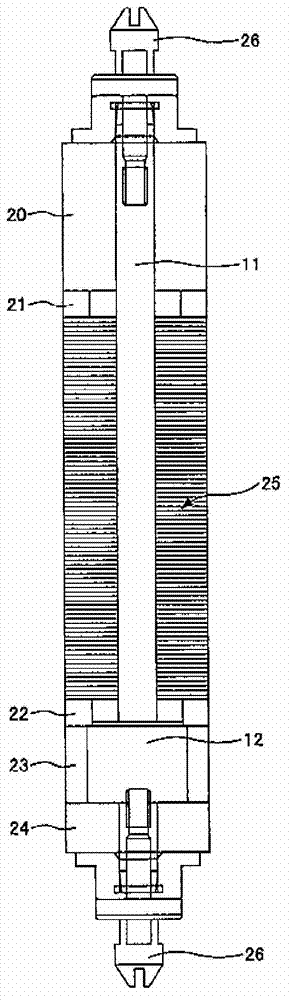

[0033] The glass substrate lamination tool of the present invention used when grinding the outer peripheral end surface and / or the inner peripheral end surface of a glass substrate laminate having a central part having a Disk-shaped glass substrates with round holes are laminated.

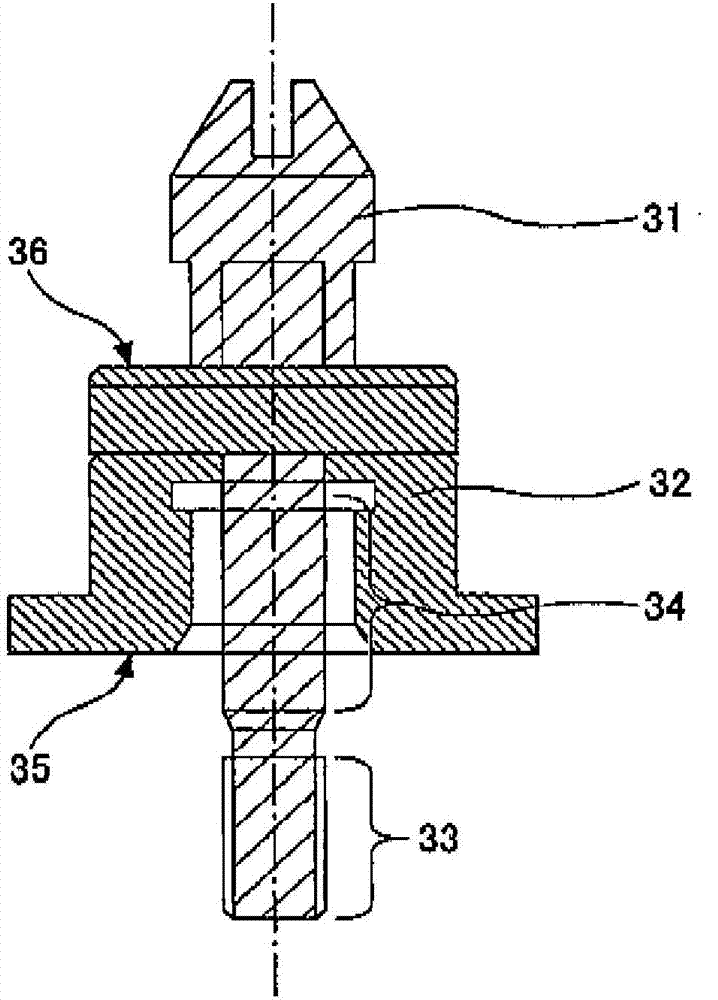

[0034] First, the glass substrate lamination tool of the present invention has a shaft inserted into a circular hole of a glass substrate for magnetic recording media to support the inner peripheral end surface of the glass substrate laminate for magnetic recording media, and to carry out the glass substrate for magnetic recording media. Alignment of substrates. And the said shaft is respectively formed with the set bolt fitting part which fits the set bolt to the both ends of a shaft, and the shaft fixing part which supports a glass substrate laminated body around a shaft.

[0035] Hereinafter, th...

no. 2 approach

[0097] This embodiment demonstrates the end face grinding method of the glass substrate for magnetic recording media using the glass substrate lamination tool demonstrated in 1st Embodiment.

[0098] Specifically, it is a method of polishing the outer peripheral end surface and the inner peripheral end surface of the glass substrate for a magnetic recording medium using the glass substrate lamination tool described in the first embodiment.

[0099] A set bolt was attached to the set bolt fitting part of the shaft which held the glass substrate laminated body, and the outer peripheral end surface of the glass substrate laminated body was grind|polished.

[0100] The shaft holding the glass substrate laminate is fixed to the inner peripheral end surface grinding tool, and after the inner peripheral end surface grinding tool fixes (clamps) the glass substrate laminate, the shaft is drawn out to grind the inner peripheral end surface of the glass substrate laminate.

[0101] Here,...

no. 3 approach

[0106] In this embodiment, the manufacturing method of the glass substrate for magnetic recording media is demonstrated.

[0107] Specifically, the manufacturing method of the glass substrate for magnetic recording media includes: the end face grinding process of grinding the inner peripheral end face and the outer peripheral end face of the glass substrate for magnetic recording media in the shape of a disc; The main plane grinding process of grinding the main plane; and the cleaning process of the glass substrate for the magnetic recording medium. Furthermore, the end face grinding step is a step of performing the end face grinding method described in the second embodiment.

[0108] In addition, it is also possible to provide a step of processing the glass substrate into a disc shape (shape imparting step) before the end face grinding step. The glass substrate used at this time is not particularly limited, and various glass substrates can be used. For example, amorphous gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com