Construction technology of large-inclined-angle and large-mining-height fully-mechanized coal mining equipment passing through geological-structured fracture zone

A technology of fully mechanized mining equipment and geological structure, applied in mining equipment, ground mining, earth-moving drilling, etc., can solve problems such as difficulty in pushing and sliding racks, failure of normal mining in working face, and roof collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

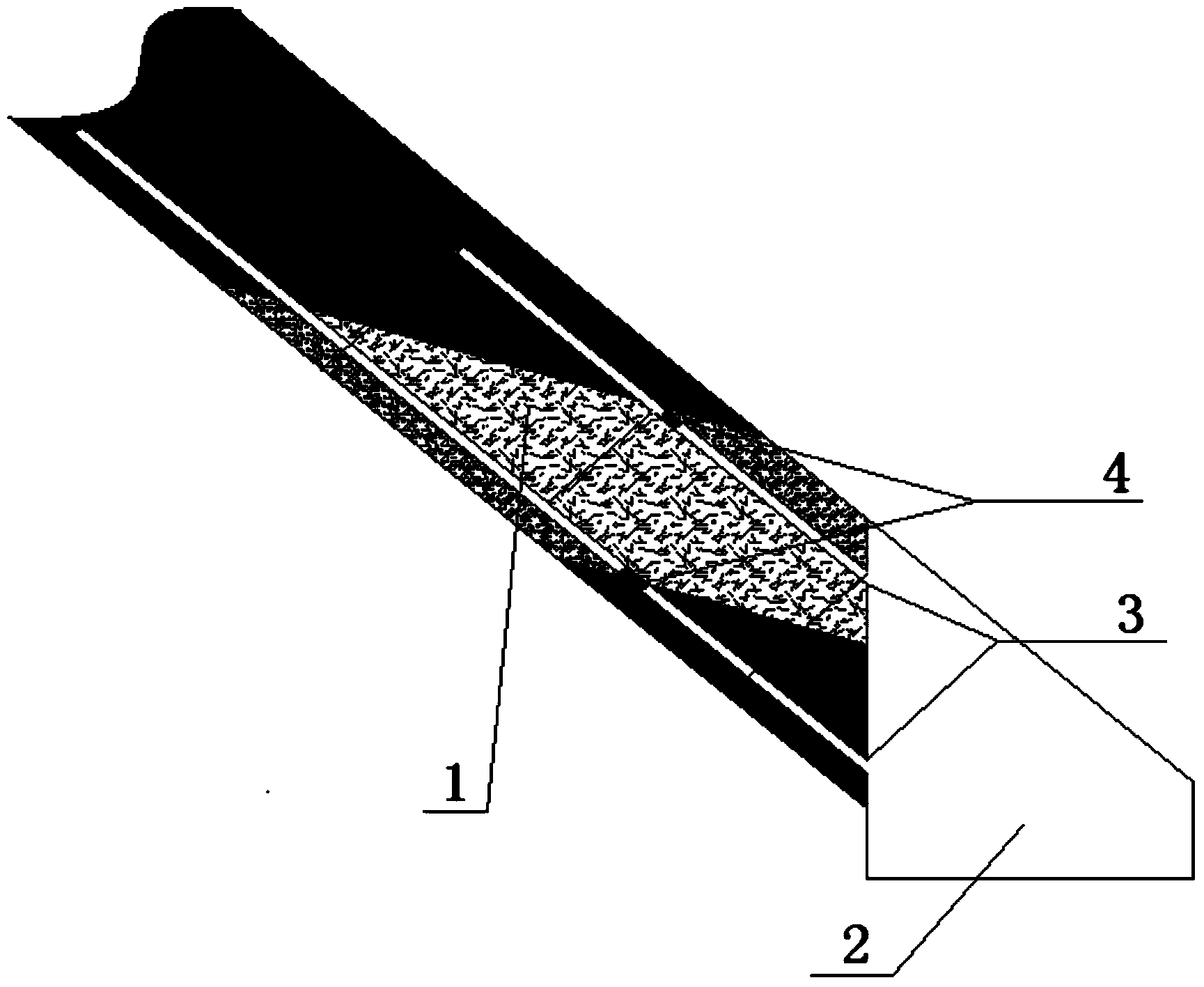

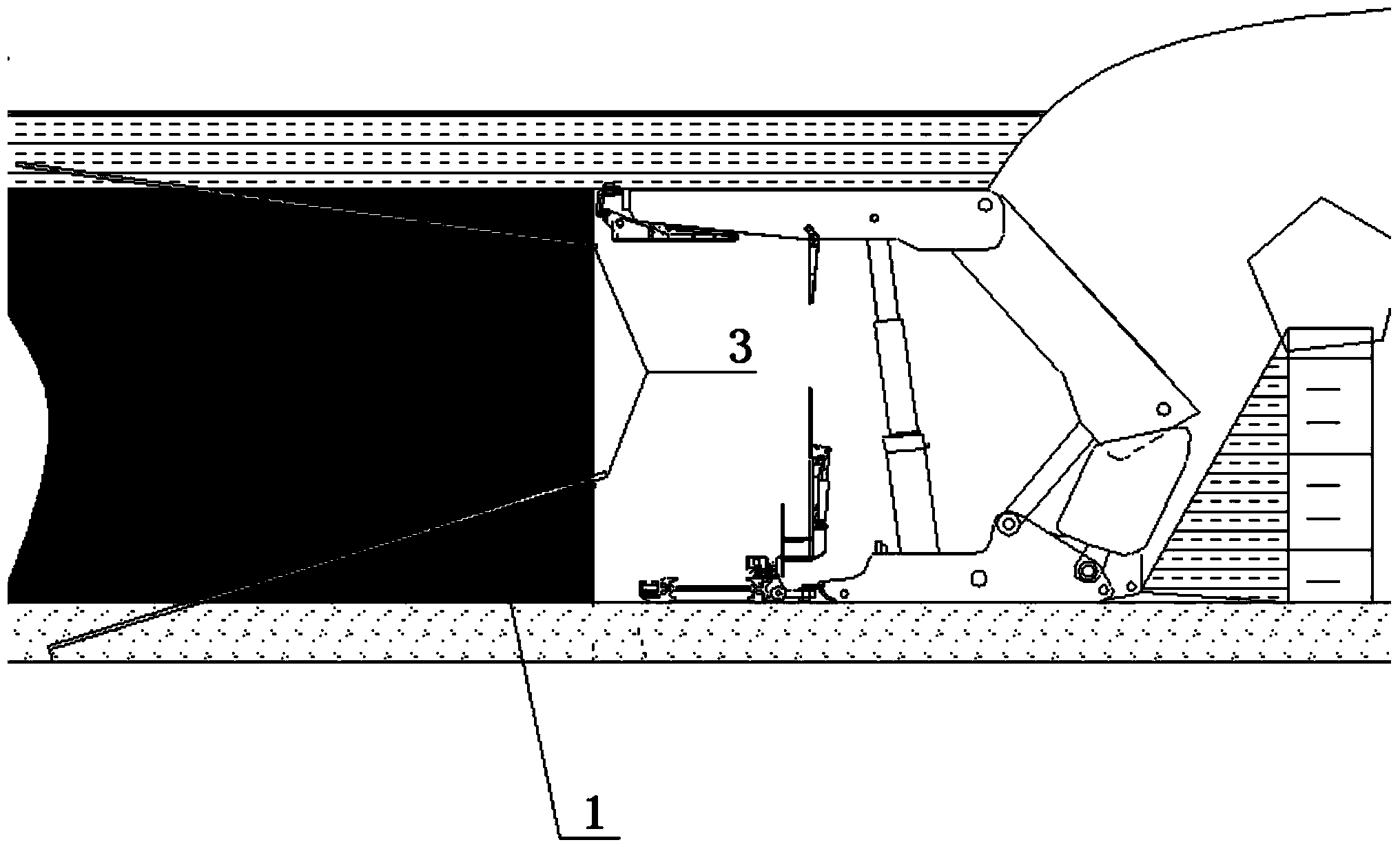

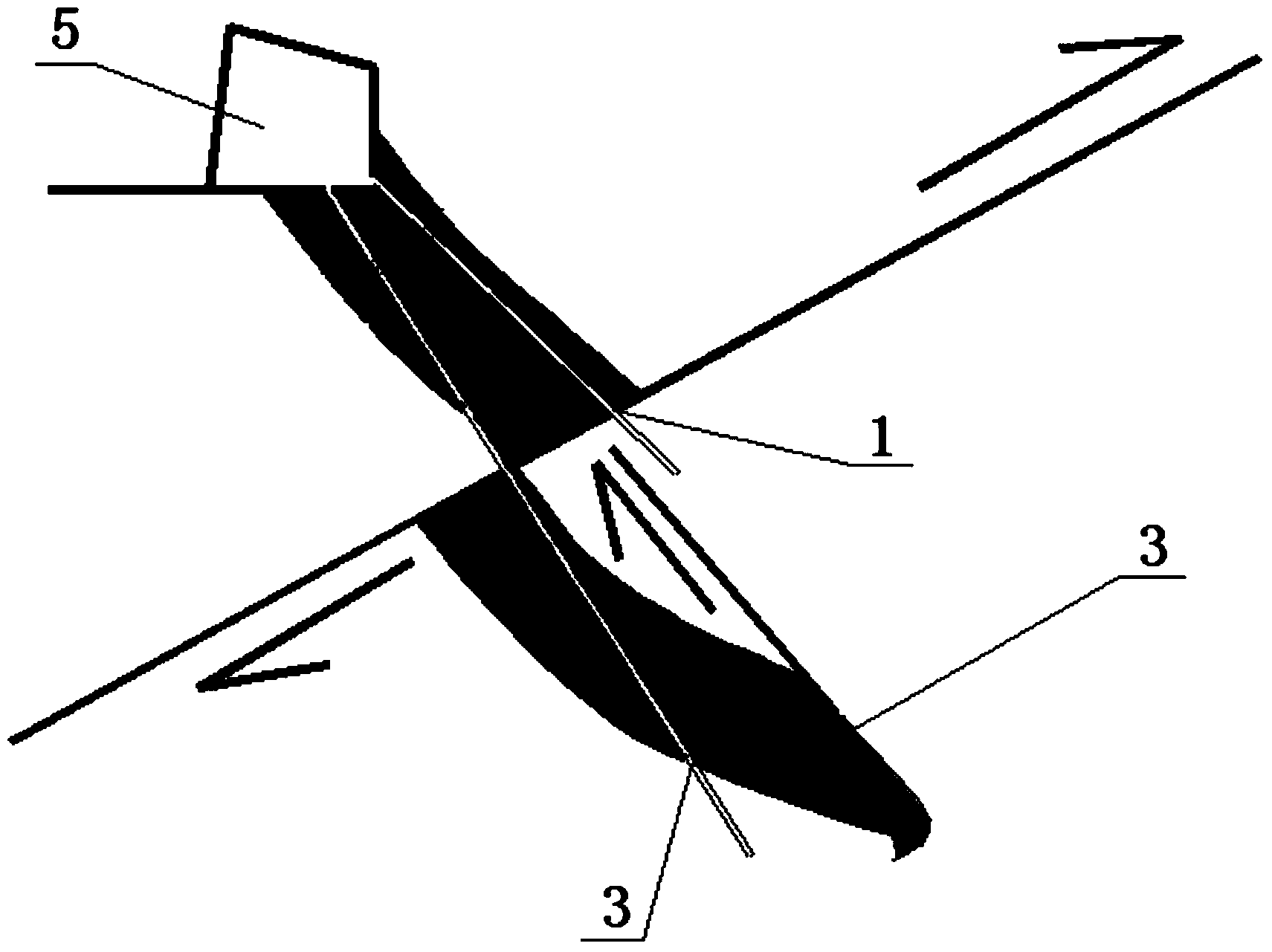

[0021] The construction process of fully mechanized mining equipment with large inclination angle and high mining height through the fracture zone of geological structure includes coal cutting process, hydraulic support moving process and scraper conveyor moving process, and the coal wall and roof grouting reinforcement process is carried out before the coal cutting process.

[0022] The details of the coal wall and roof grouting reinforcement procedures are as follows:

[0023] The coal wall and roof are solidified in deep holes by using Meigu 364 two-component soluble silicate resin produced by BASF Chemical Building Materials (China) Co., Ltd.

[0024] Meigu 364 has strong permeability and can penetrate into gaps with a width of more than 0.14mm. The solidification time is about 2 minutes; the bond strength reaches 4MPa after 6 minutes of sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com