Magneto-rheological valve structure with a combined three-dimensional helical flow channel

A liquid flow channel, three-dimensional spiral technology, applied in the field of hydraulic control valves, can solve the problems of increasing the valve volume, not making full use of the coil magnetic field, increasing the difficulty of assembling magnetorheological valves, and increasing the failure rate, so as to improve the pressure difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

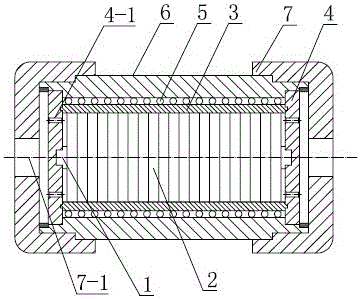

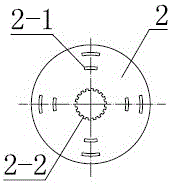

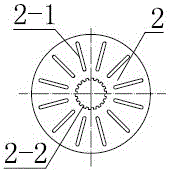

[0013] Referring to the accompanying drawings, a magneto-rheological valve structure with a combined three-dimensional spiral liquid flow channel includes a valve body 6, a valve body end cover 7, an oil inlet and outlet pan 4, an excitation coil 5, and a valve core part. The valve core part It includes: a valve core shaft 1, a liquid flow channel plate 2 and a sleeve 3. The liquid flow channel plate 2 is provided with a group, and the liquid flow channel plate 2 is provided with a liquid flow channel long hole 2-1, and the liquid flow channel Disks 2 are installed on the spool shaft 1 in turn, and the designed installation angles differ between adjacent liquid flow channel disks 2, forming a combined three-dimensional spiral liquid formed between the long holes 2-1 of the liquid flow channel on the liquid flow channel disk 2. The flow channel structure, the spool shaft 1 is installed on the oil inlet and outlet pan 4, the sleeve 3 is set on the outer circle of the flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com