Chain shaft of chain and manufacturing method thereof

A manufacturing method and chain shaft technology, which are applied to the lubrication of belts/chains/gears, chain elements, and engines, can solve the problems of wear and service life of chain components, and the lubrication effect is not easy to last and shorten, so as to increase the oil storage space, The effect of improving smoothness and wear resistance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

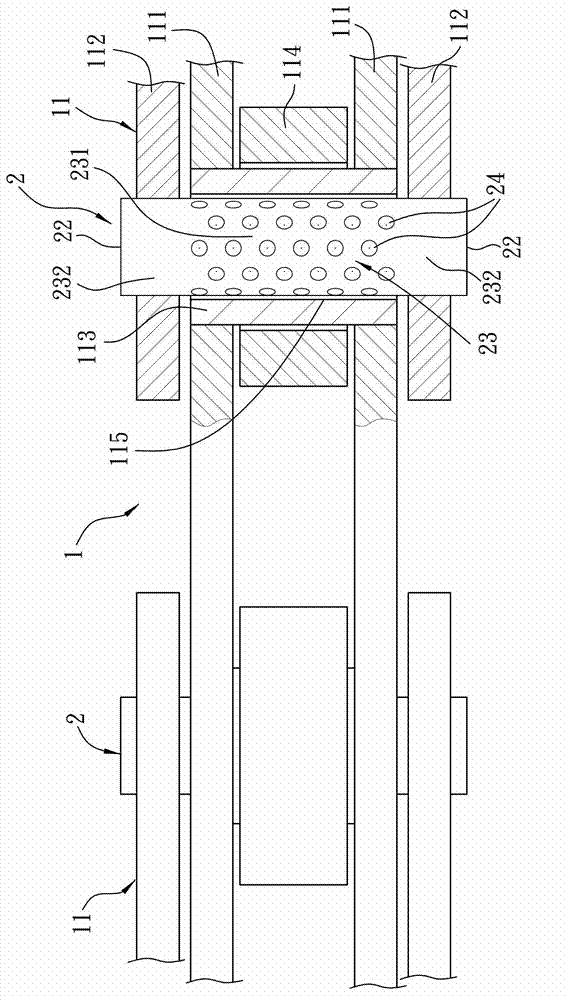

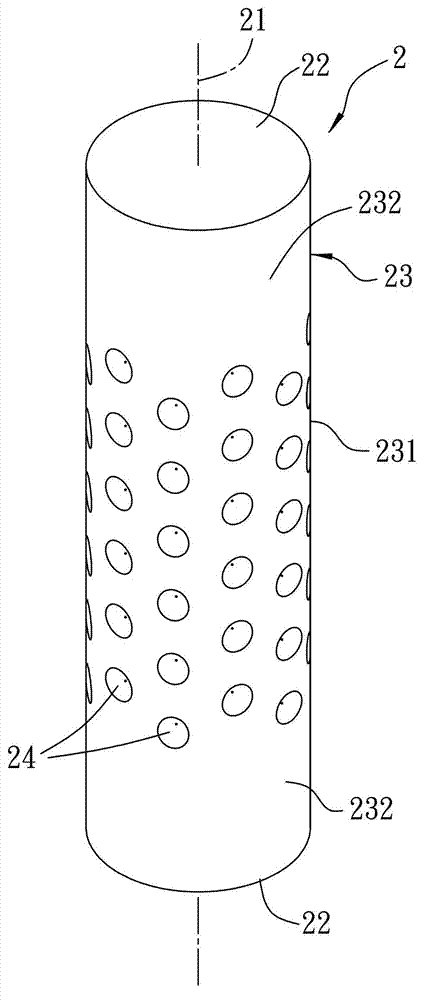

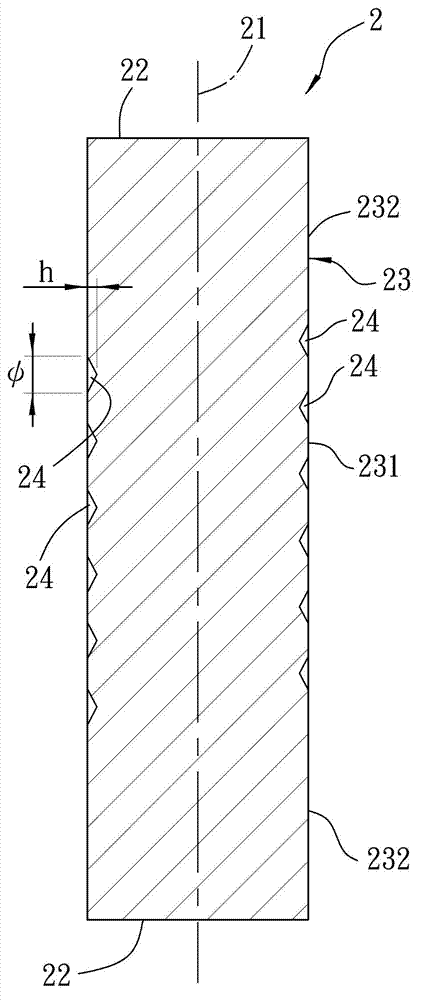

[0027] refer to figure 1 , figure 2 and image 3 , the preferred embodiment of the chain shaft 2 of the present invention is that several are installed at intervals on a chain 1, and the chain 1 includes several ring-shaped series connection units 11 connected in series from head to tail, each of which is connected in series In addition to the chain shaft 2, the unit 11 also includes two inner chain pieces 111 that are sheathed on the outer periphery of the chain shaft 2 at intervals and oppositely, and two inner chain pieces 111 that are respectively located outside the inner chain pieces 111 and are connected to the chain shaft 2. Outer chain pieces 112 at both ends, a bushing 113 sleeved on the periphery of the chain shaft 2 and both ends combined with the inner chain piece 111 , and a bushing 113 sleeved on the periphery of the bushing 113 and located on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com