Crude oil purification system and oil storage tank cleaning system

A technology for purification systems and oil storage tanks, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve problems such as reducing the utilization rate of storage tanks, affecting the quality of crude oil, and inability to separate moisture and impurities, and achieve Increase oil storage space, improve quality, achieve cleaning and discharge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

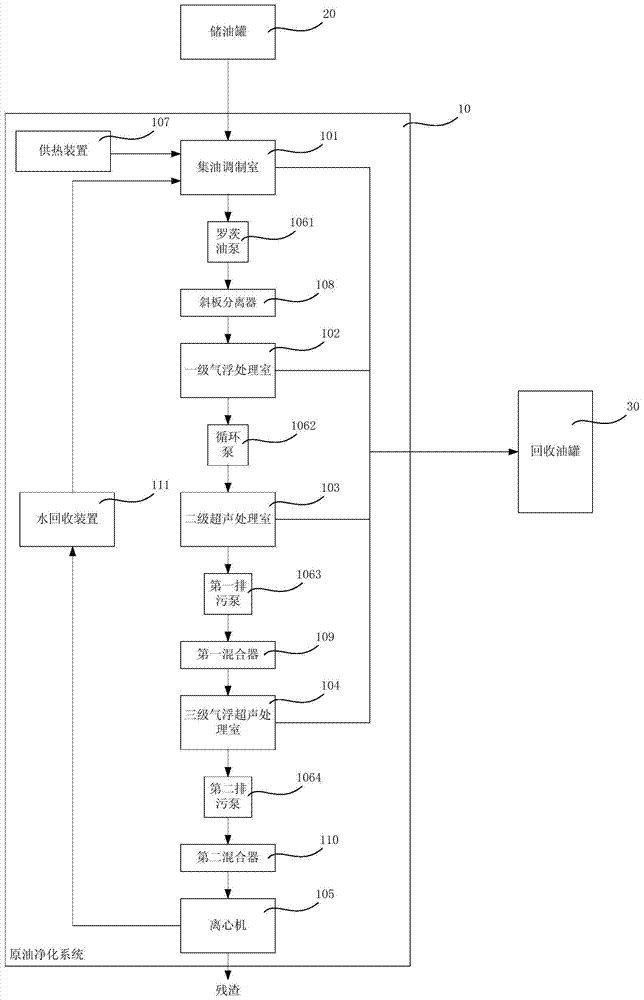

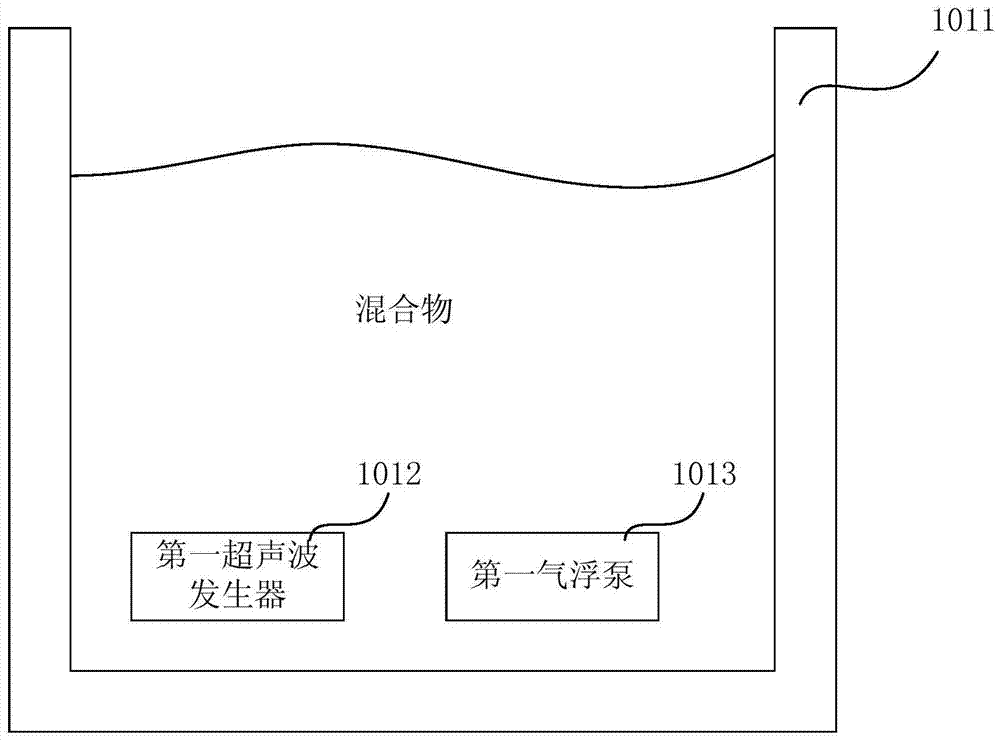

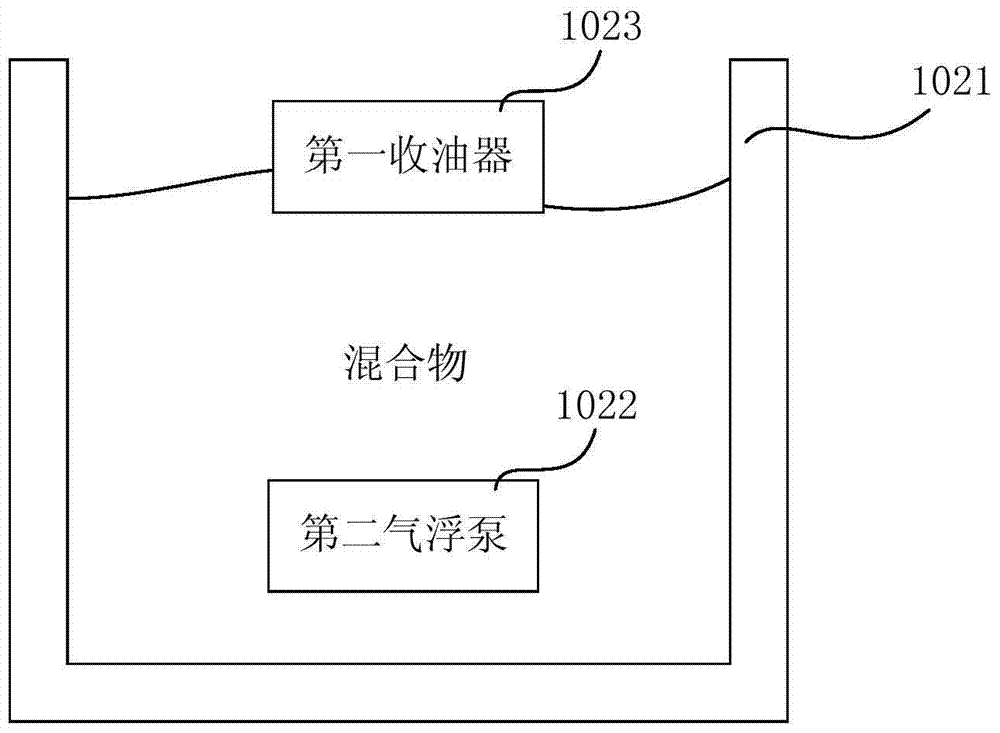

[0069] like figure 1 As shown, the crude oil purification system 10 provided by the embodiment of the present invention mainly includes an oil collection and preparation chamber 101, a primary air flotation treatment chamber 102, a secondary ultrasonic treatment chamber 103, a tertiary air flotation ultrasonic treatment chamber 104, a centrifuge 105 and Conveyor set. Wherein, the oil collection and preparation chamber 101 performs demulsification and stirring of the hot water and the crude oil transported from the oil storage tank 20 to form a mixture. The primary air flotation treatment chamber 102 preliminarily separates the mixture transported from the oil collection preparation chamber 101 under the action of air flotation, and transports the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com