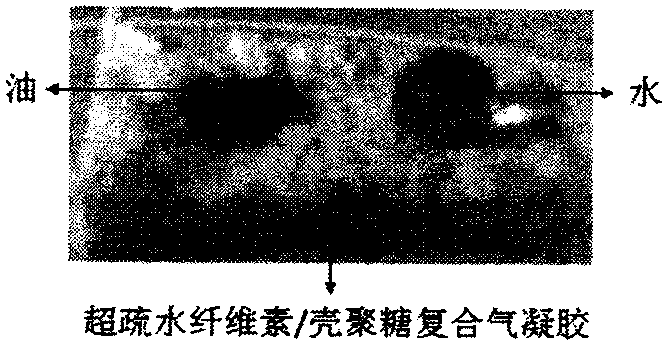

A preparation method of superhydrophobic cellulose/chitosan composite airgel oil-water separation material

A composite aerogel and composite hydrogel technology is applied in the field of preparation of superhydrophobic cellulose/chitosan composite aerogel oil-water separation materials, which can solve the problem of destroying the modified substrate structure, wasting modifiers, modifying Low efficiency and other problems, to achieve the effect of wide source, large oil storage space, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The first step: preparation of cellulose / chitosan composite solution

[0018] Take 40 parts of deionized water, 3.5 parts of sodium hydroxide and 6 parts of urea into the reactor, stir at -15°C for 0.5 hours, then add 0.5 parts of cellulose and 1.5 parts of chitosan, at 1000r / min Stirring 10h at a certain stirring speed to obtain a cellulose / chitosan mixed solution. The obtained mixed solution was cooled to -20°C, frozen for 12 hours to obtain a solid, taken out, thawed and stirred at 25°C for 30 minutes, and obtained a uniform cellulose / chitosan composite solution through 2 freeze-thaw cycles, at 10000r / min Centrifuge for 5 minutes under the condition of rotating speed to remove air bubbles to obtain a transparent cellulose / chitosan composite solution, which is set aside.

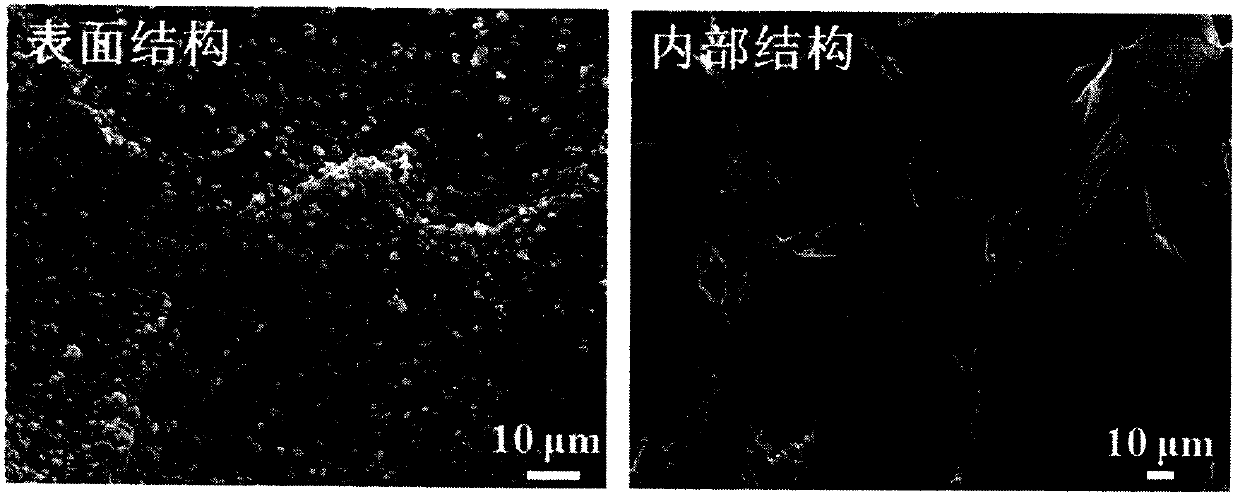

[0019] The second step: Preparation of cellulose / chitosan composite airgel

[0020] Take 30 parts of cellulose / chitosan composite solution, pour it into a mold, freeze at -20°C for 12 hours to obt...

Embodiment 2

[0024] The first step: preparation of cellulose / chitosan composite solution

[0025] Take 50 parts of deionized water, 2.5 parts of sodium hydroxide and 3 parts of urea into the reactor, stir at -15°C for 0.5 hours, then add 1.5 parts of cellulose and 0.5 parts of chitosan, at 800r / min Stir for 12h at a certain stirring speed to obtain a cellulose / chitosan mixed solution. The resulting mixed solution was cooled to -20°C, frozen for 12 hours to obtain a solid, taken out, thawed and stirred at 25°C for 30 minutes, and obtained a uniform cellulose / chitosan composite solution through 3 freeze-thaw cycles, at 10000r / min Centrifuge for 5 minutes under the condition of rotating speed to remove air bubbles to obtain a transparent cellulose / chitosan composite solution, which is set aside.

[0026] The second step: Preparation of cellulose / chitosan composite airgel

[0027] Take 60 parts of cellulose / chitosan composite solution, pour it into a mold, freeze at -20°C for 12 hours to obt...

Embodiment 3

[0031] The first step: preparation of cellulose / chitosan composite solution

[0032] Take 80 parts of deionized water, 7 parts of sodium hydroxide and 12 parts of urea into the reaction kettle, stir at -15°C for 1 hour, then add 2.5 parts of cellulose and 1.5 parts of chitosan, at 1200r / min Stir at a stirring speed for 10 h to obtain a cellulose / chitosan mixed solution. The obtained mixed solution was cooled to -20°C, frozen for 12 hours to obtain a solid, taken out, thawed and stirred at 25°C for 30 minutes, and obtained a uniform cellulose / chitosan composite solution through 4 freeze-thaw cycles, at 10000r / min Centrifuge for 5 minutes under the condition of rotating speed to remove air bubbles to obtain a transparent cellulose / chitosan composite solution, which is set aside.

[0033] The second step: Preparation of cellulose / chitosan composite airgel

[0034] Take 90 parts of cellulose / chitosan composite solution, pour it into a mold, freeze at -20°C for 12 hours to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com