Hollow rotating and twisting sealing structure for fried dough twist machine

A kind of twist machine and hollow technology, which is applied in the direction of engine sealing, dough twisting machinery, mechanical equipment, etc., can solve problems such as leakage, and achieve the effect of tightness, no leakage and good sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

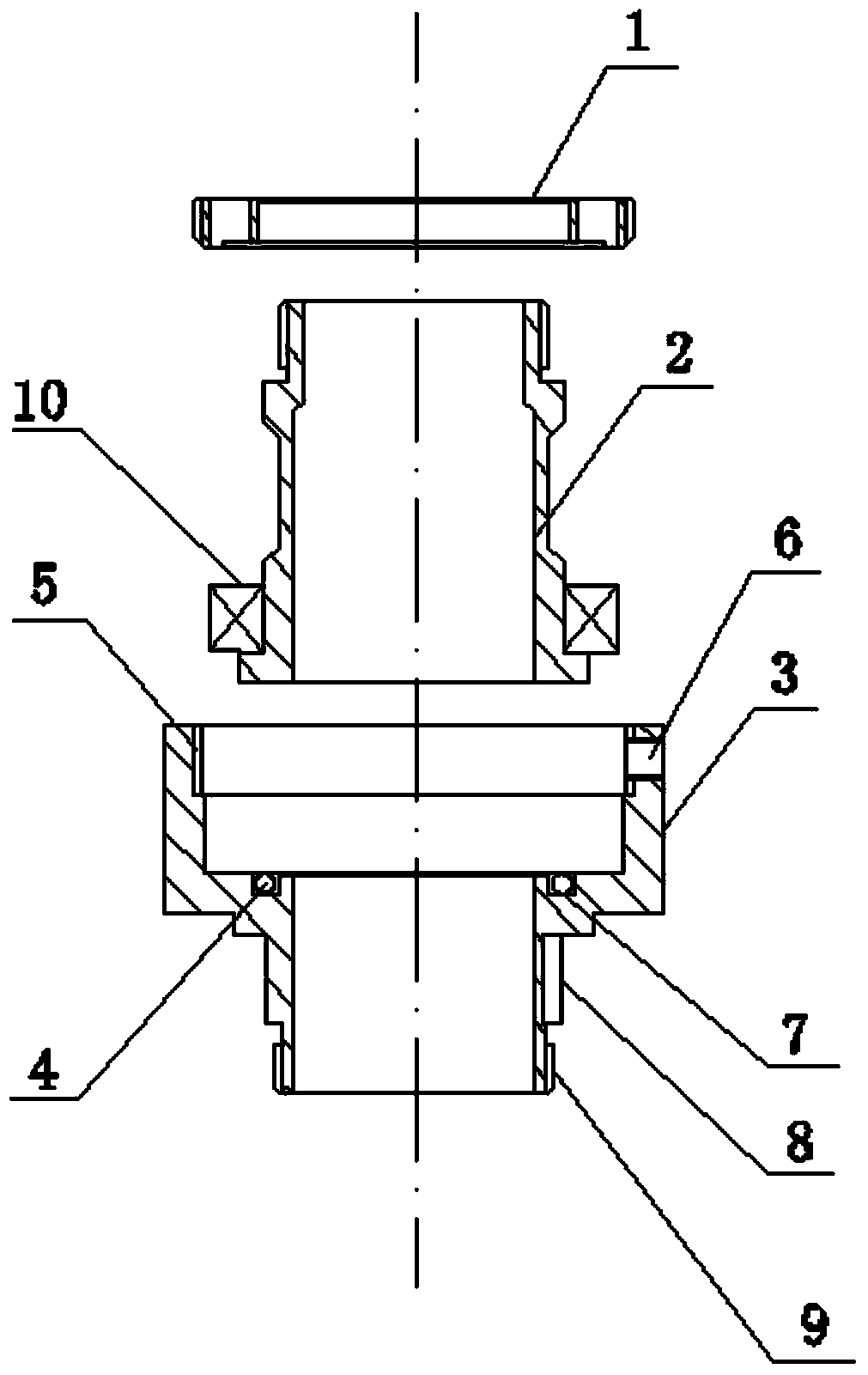

[0010] As shown in the drawings, the hollow rotary twisted strand sealing structure of a twist machine in this embodiment is composed of a compression adjustment cover 1, a small noodle cylinder 2, a small noodle bowl 3, an O-ring 4 and a bearing 10. , the O-shaped sealing ring 4 is located in the groove 7 on the bottom surface of the large round hole provided on the top of the small noodle bowl 3, and the small noodle cylinder 2 is arranged in the large circular hole provided on the top of the small noodle bowl 3 and the lower end surface of the small noodle cylinder 2 will be O Type sealing ring 4 is fixed in the groove 7 of the bottom surface of the big round hole, and the bearing 10 is located at the bottom of the small noodle cylinder 2 and is positioned between the outer wall of the small noodle cylinder 2 and the inner wall of the large round hole of the small noodle bowl 3. The top of the face bowl 3 large circular hole inwalls is connected and the bearing 10 is fixed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com