Breakdown failure positioning method of GIS on-site voltage withstand test based on vibration test

A technology of fault location and withstand voltage test, which is applied in the direction of testing the dielectric strength, etc., can solve the problems of affecting the construction progress of the site, the scope is large, and the location of the fault cannot be determined intuitively, so as to avoid the trouble of large-scale disintegration inspection and improve On-site construction progress and the effect of eliminating quality hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

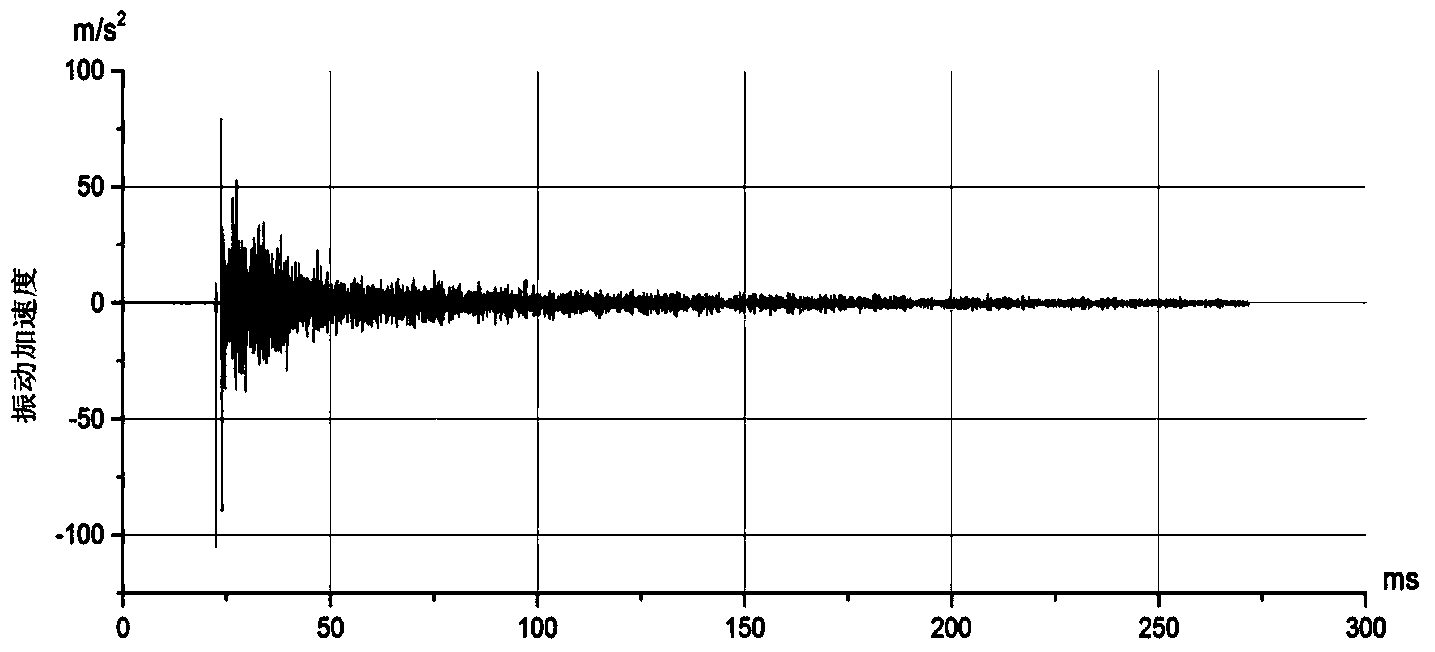

[0020] A breakdown fault location method based on vibration test of GIS field withstand voltage test. Multiple vibration sensors are arranged on the GIS shell within the tested range for monitoring, and vibration signals when GIS breakdown faults occur are collected, and analyzed by comparison. The amplitude difference and time difference between the signals of the measuring points are used to locate the fault. The position vibration sensors described above can cover the tested GIS.

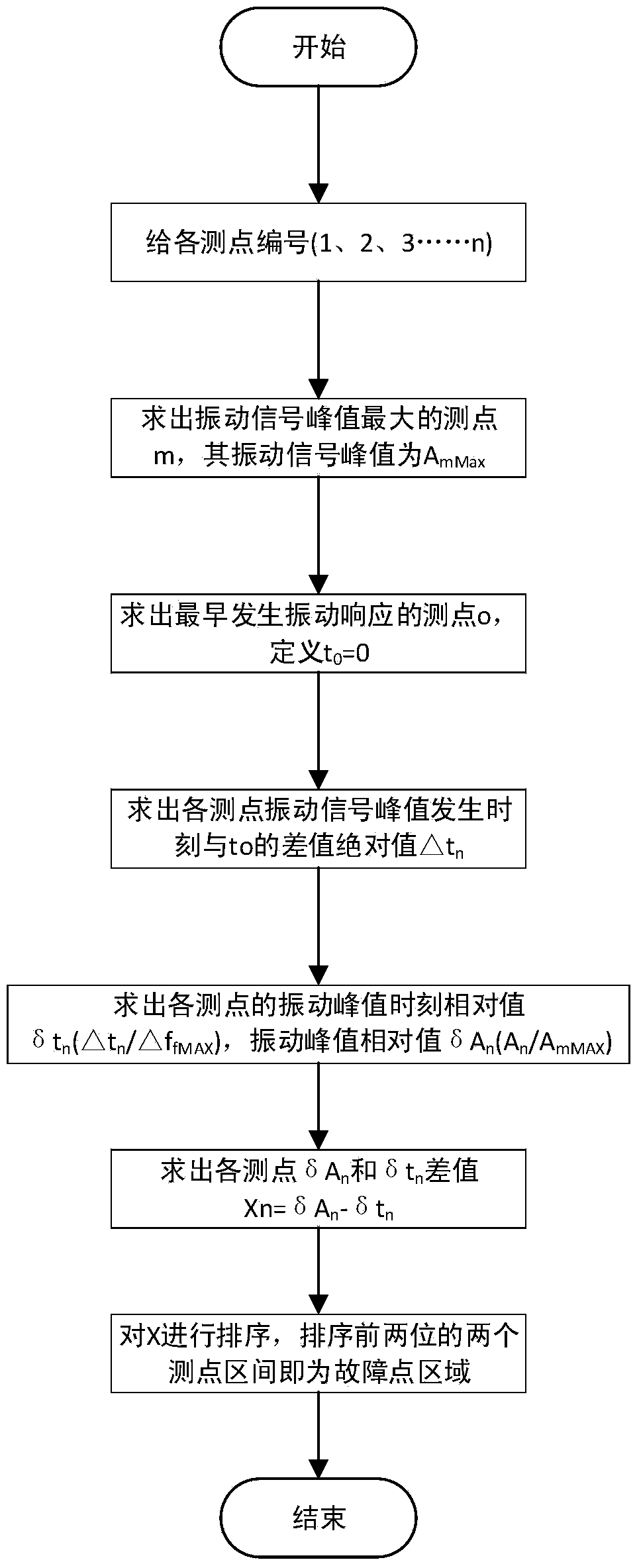

[0021] Such as figure 2 Shown, the present invention specifically comprises the following steps:

[0022] 1) Number n for each position vibration sensor, where n=1, 2...k;

[0023] 2) Find the test point m with the largest vibration signal peak value, and its vibration signal peak value is A mMAX ;

[0024] 3) Obtain the test point O where the vibration response occurs earliest, and define the peak position of the test point as A o , and define the moment corresponding to the peak position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com