Patents

Literature

54results about How to "Speed up on-site construction progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

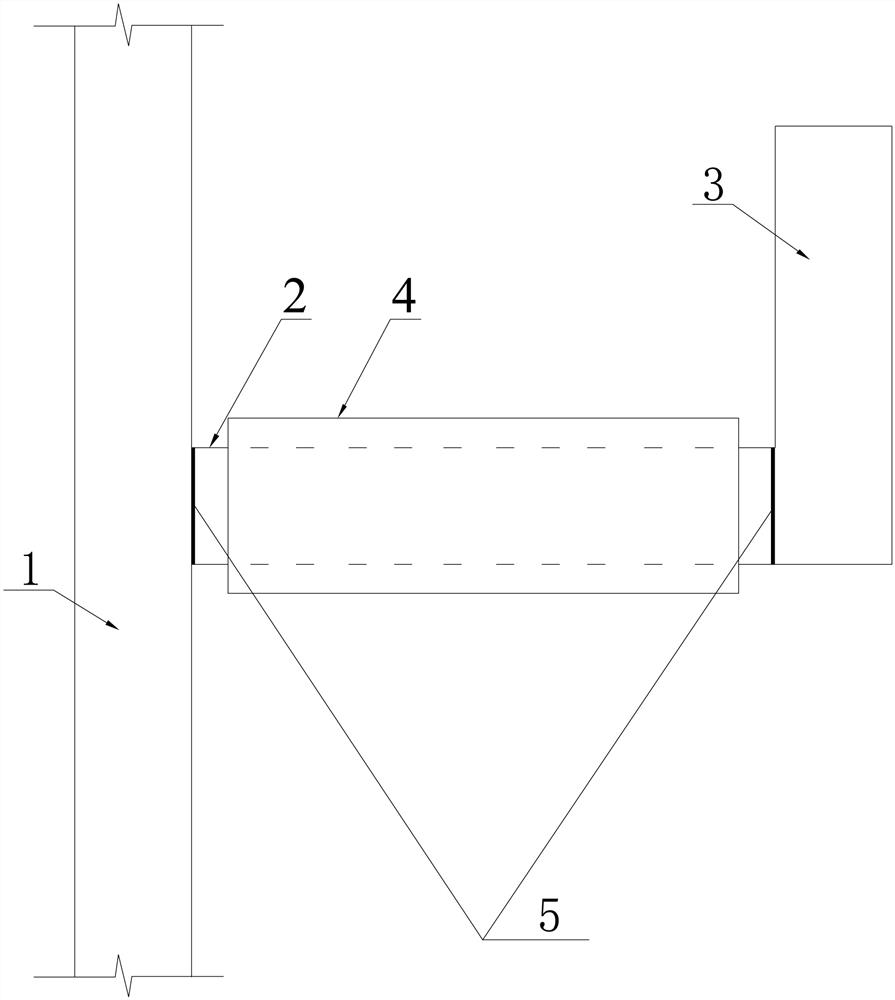

Bidirectional prefabricated segment splicing construction method for large-sized underpass

ActiveCN105002931AReduce distractionsUniform stress distribution on the bonding surfaceArtificial islandsUnderwater structuresSteel platesRebar

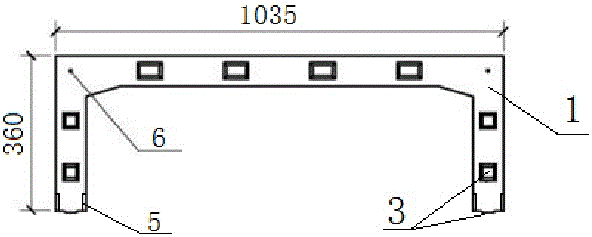

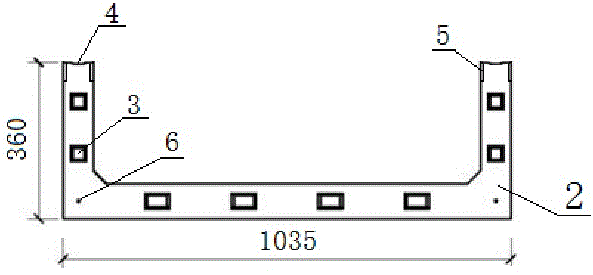

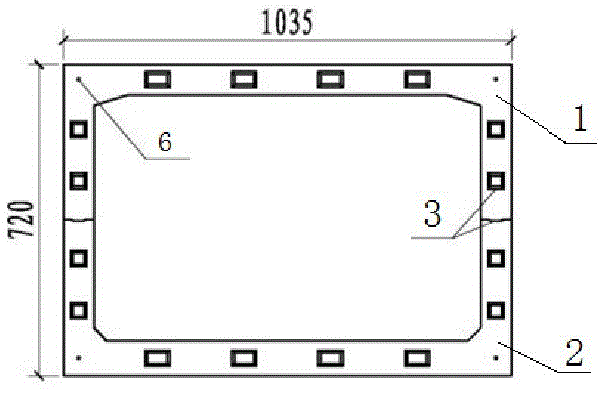

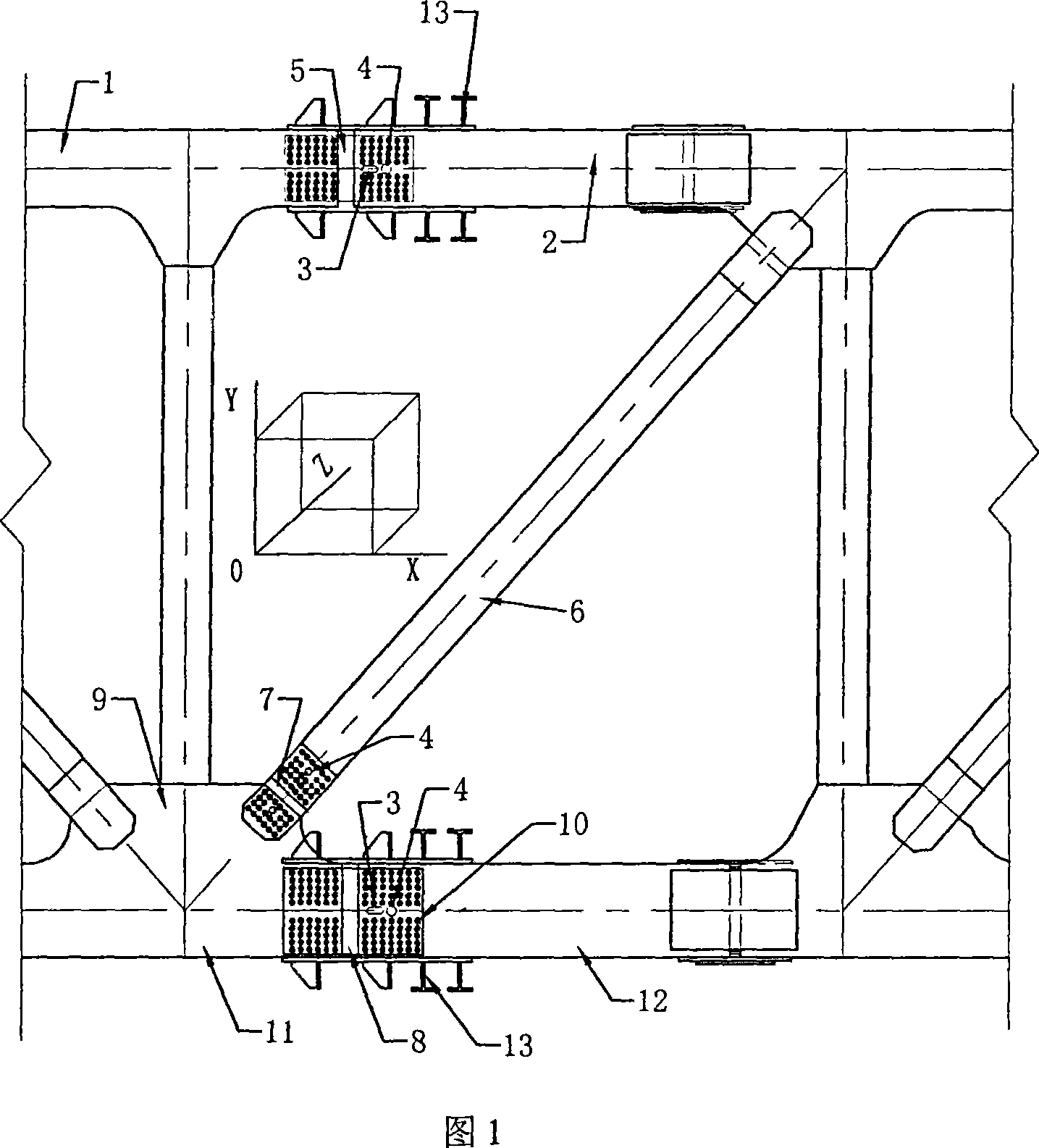

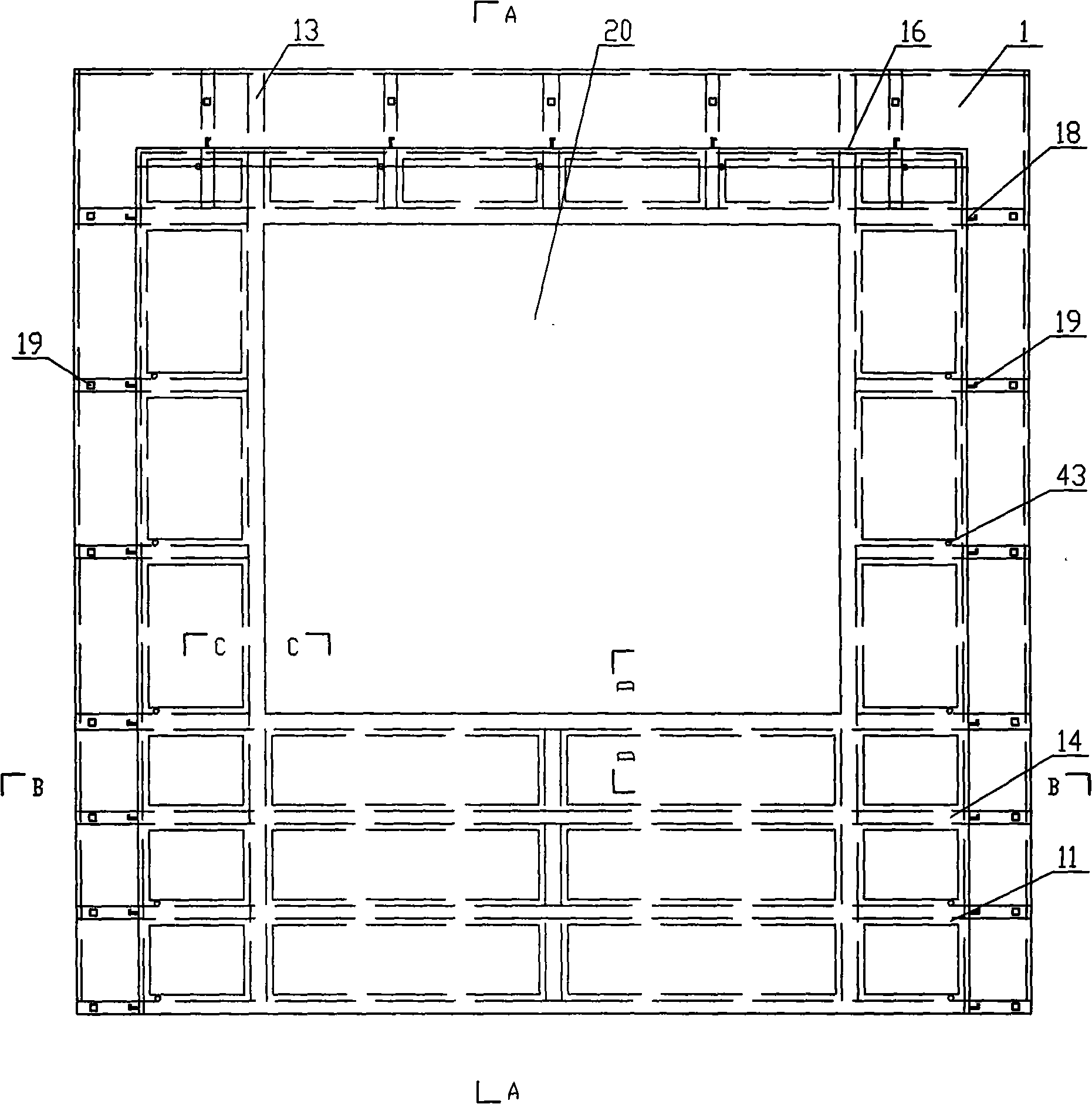

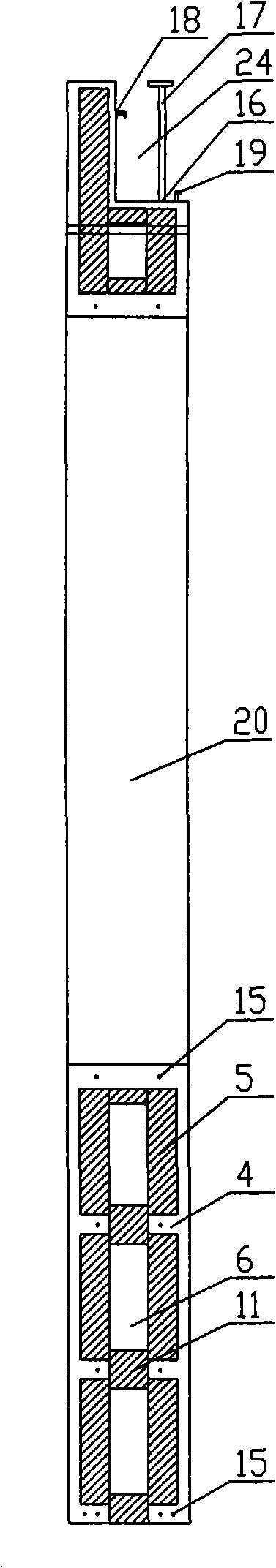

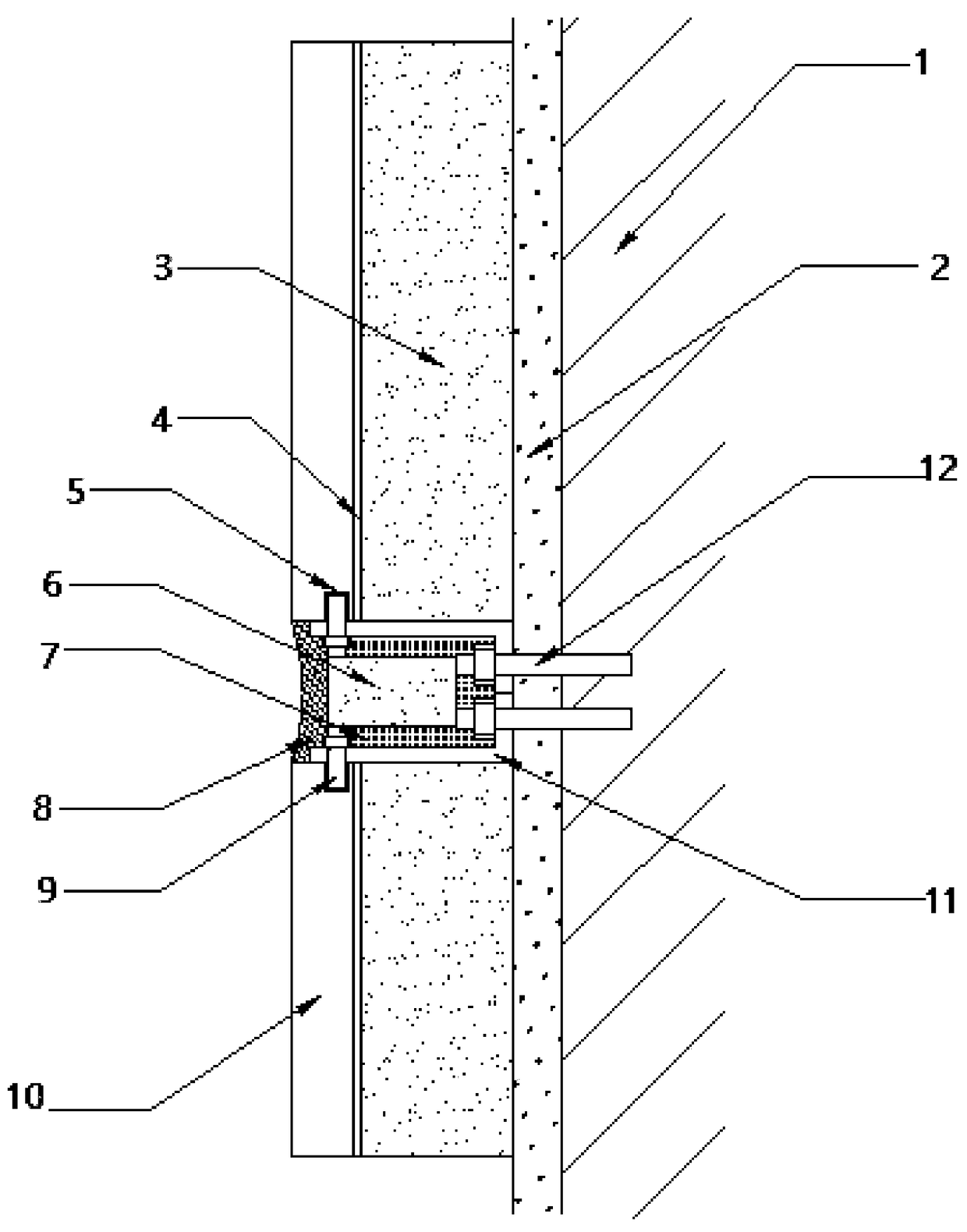

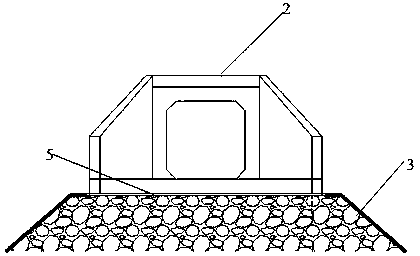

The invention discloses a bidirectional prefabricated segment splicing construction method for a large-sized underpass and belongs to the technical field of traffic engineering. A closed frame structure of the underpass is formed through splicing by adopting the prefabricated segment splicing construction method. Shear keys are arranged on longitudinal splicing surfaces and vertical splicing surfaces respectively. Splicing seams are bonded through structural adhesives. Pressure is formed for vertical splicing by means of self-weight. The vertical splicing seams are provided with connecting steel plates. The connecting steel plates are welded to pre-embedded steel plates of upper segments and lower segments after bonding is completed. Temporary pre-stressing force is set for longitudinal splicing. Large-segment post-tensioning permanent pre-stressing force is longitudinally formed, so that the integrality of each large segment is guaranteed for a long time. Factory-like prefabrication of the prefabricated segments is adopted and carried out in synchronization with excavation of a foundation pit. Thus, certain-scale urban road reconstruction bringing traffic interference seriously influencing production and life in the construction period is carried out smoothly, the construction duration is greatly shortened, the on-site construction progress is promoted, the number of construction procedures of on-site formwork erection, reinforcing steel bar cutting, binding and welding, concrete pouring and the like is substantially reduced, and dust and noise pollution to perimeter zones is reduced.

Owner:XIAMEN MUNICIPAL ENGINEERING DESIGN INSTITUTE CO LTD

Large-span bridge steel girder closing construction method

InactiveCN101158147AHigh precisionRealize zero error closingBridge erection/assemblyEngineeringMiddle line

The invention relates to a construction method of steel girder closure in large span bridges, and is characterized in that: a lower chord is closed firstly, an upper chord is closed secondly, and slant rods are closed finally. In construction, a structure method of 'a long round hole plus a round hole closure hinge' is adopted. The Z-direction of a left lower chord rod and a right lower chord rod of the closure point is adjusted at first to go through two trusses midline; then the Y direction is adjusted to close the long round hole on the lower chord closure with nails punched; and the X direction is adjusted after the closure of the long round hole and then a high bolt goes through the round hole in the lower chord closure point to close. If Z direction deviation is not big, a jack can be arranged on the top face and bottom face of the left lower chord rod of the closure point and the right chord rod of the closure point and tension adjustment is conducted in the two sides of the closure segment. According to calculation, every cable release tension at different tons to diminish the deviations in Y and Z directions to be close to closure requirements. The lower chord rod and the slant rod are closed in order. The invention has the advantages that by adopting the structure method of 'a long round hole plus a round hole closure hinge', the steel girder closure precision is high and zero error closure is achieved; the construction risk of field operation is lowered; and field construction progress is quickened.

Owner:THE 2ND ENG CO LTD MBEC

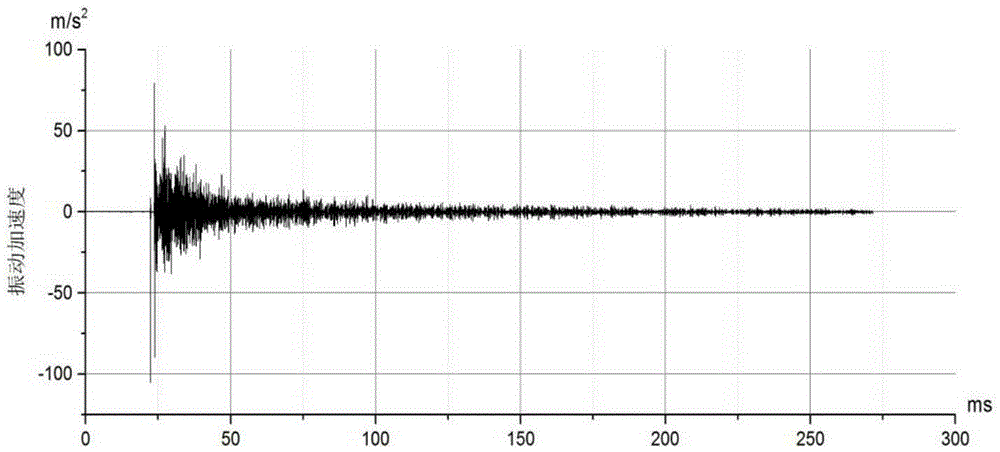

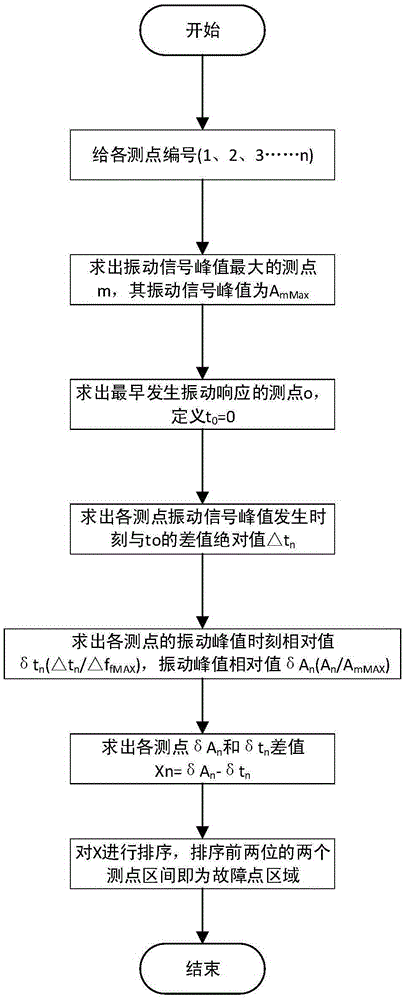

Breakdown failure positioning method of GIS on-site voltage withstand test based on vibration test

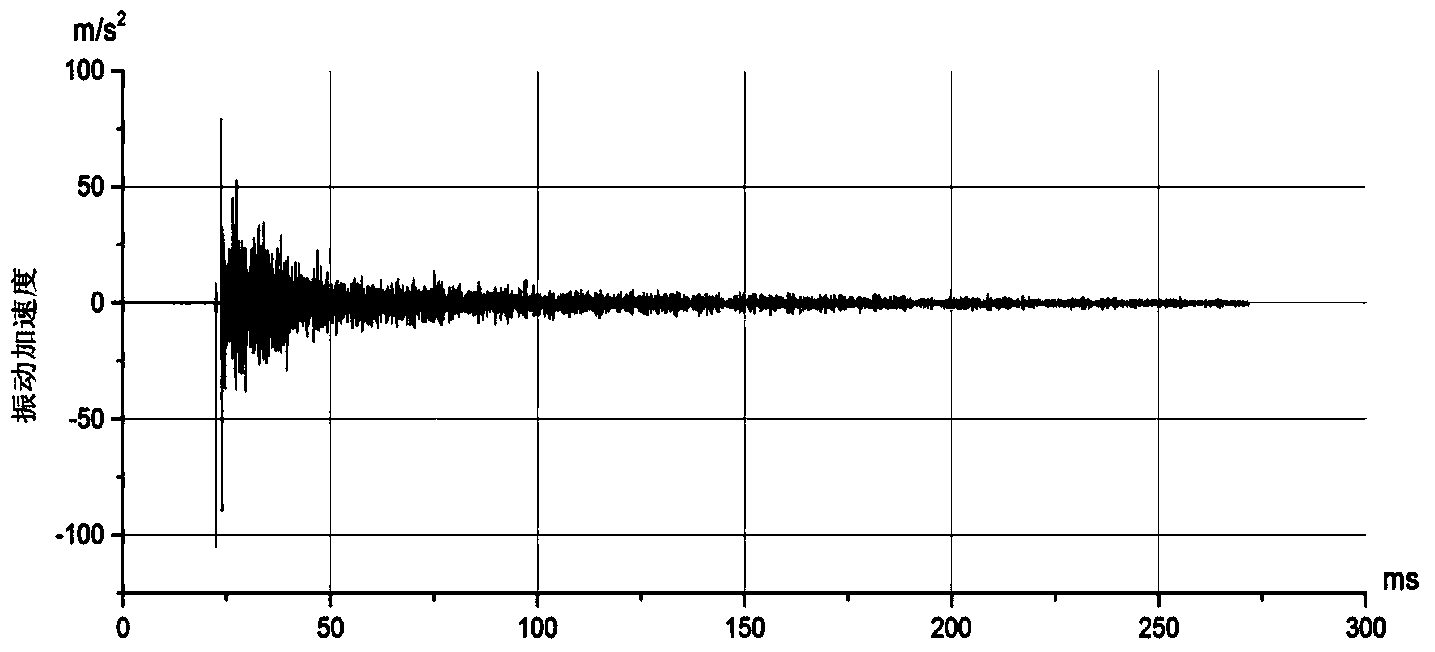

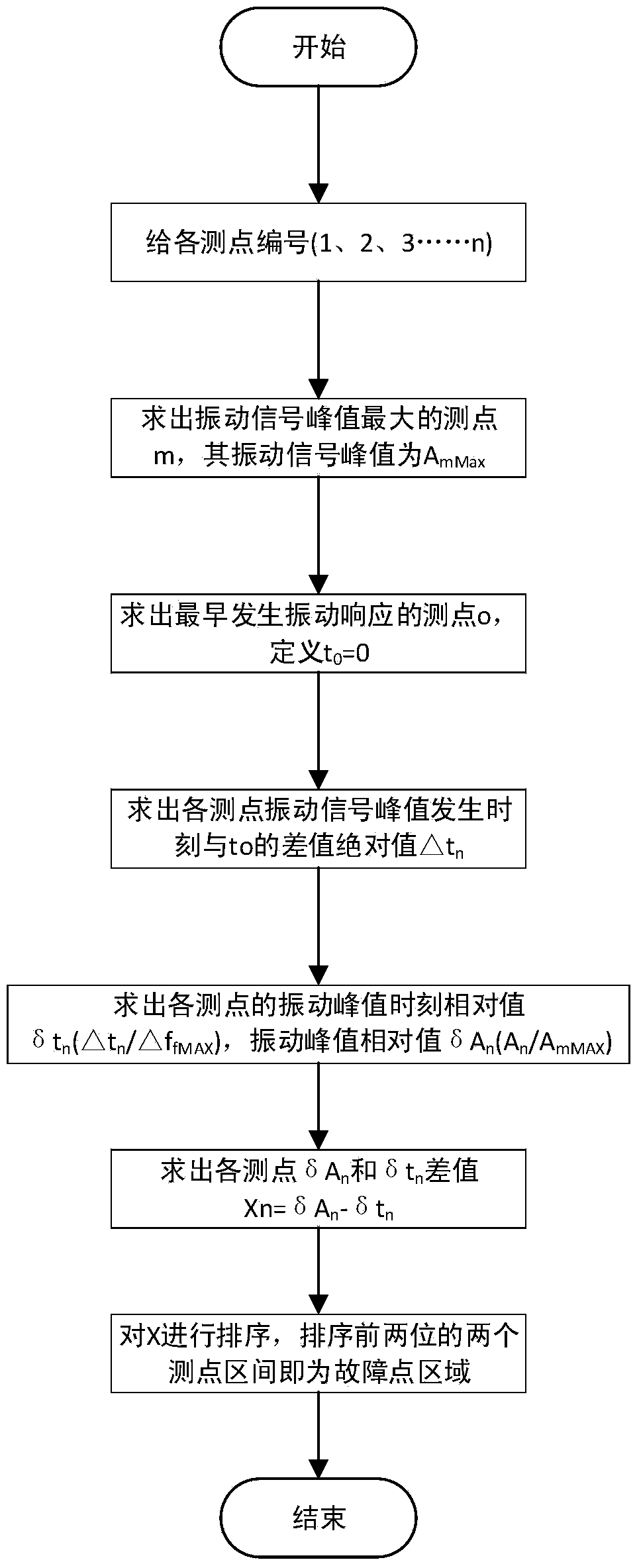

ActiveCN103777124AImprove test accuracyAvoid the trouble of large-scale disassembly inspectionTesting dielectric strengthTime differenceReliability engineering

The invention relates to a breakdown failure positioning method of a GIS on-site voltage withstand test based on a vibration test. A plurality of vibration sensors are distributed on a GIS outer shell within a test range to carry out monitoring, the vibration signals generated when a GIS breakdown failure occurs are collected, and failure positioning is carried out by comparing the amplitude difference and time difference between monitoring point signals. Compared with the prior art, the breakdown failure positioning method of the GIS on-site voltage withstand test based on the vibration test has the advantages of being high in test accuracy and saving the trouble of large-area detachment examination by achieving failure positioning through the vibration test, thereby effectively improving the on-site construction progress, and meanwhile eliminating quality hidden risks caused by large-area detachment.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

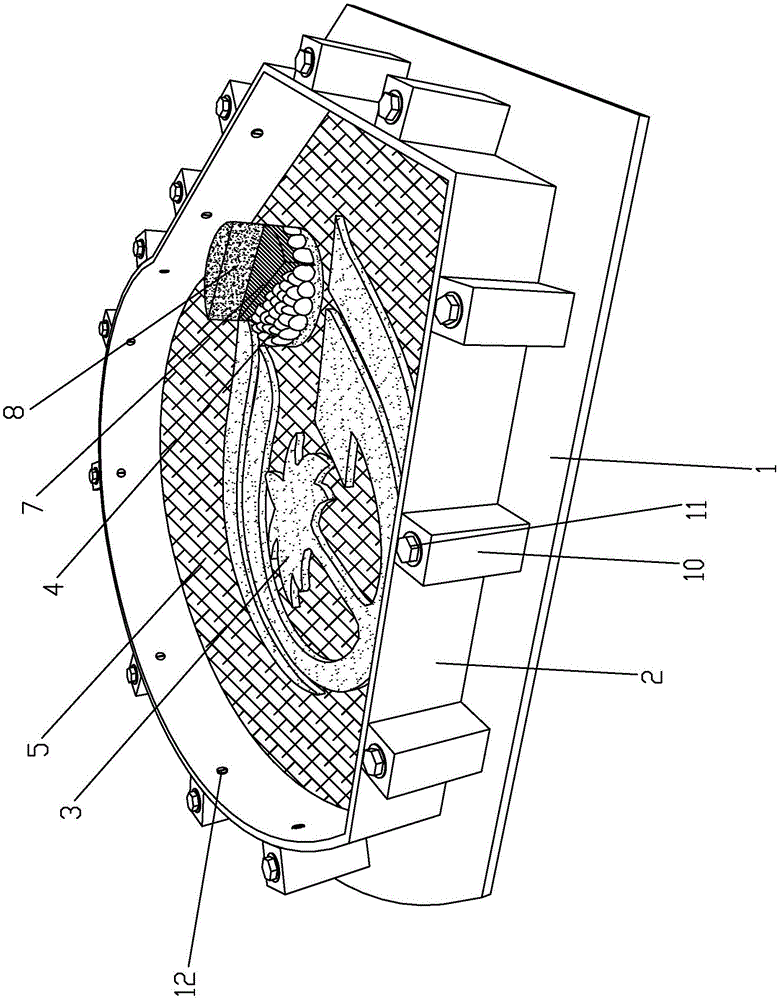

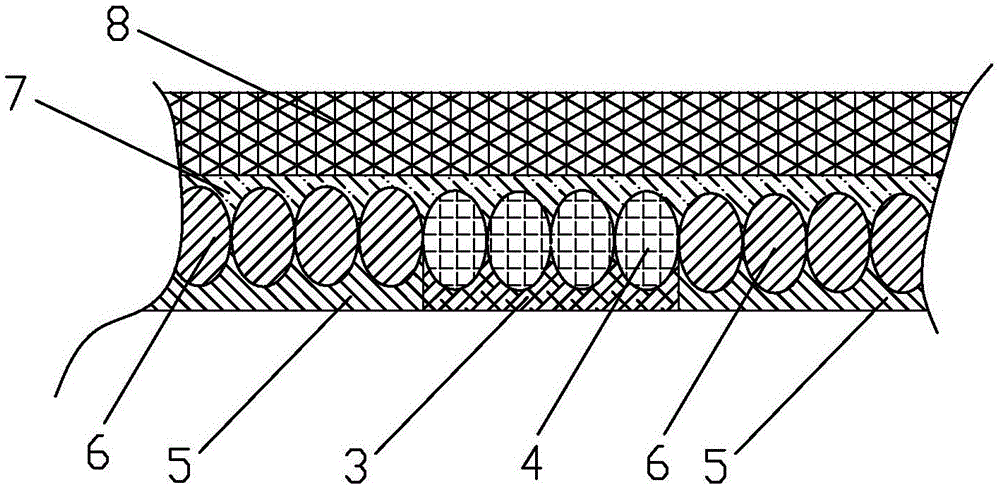

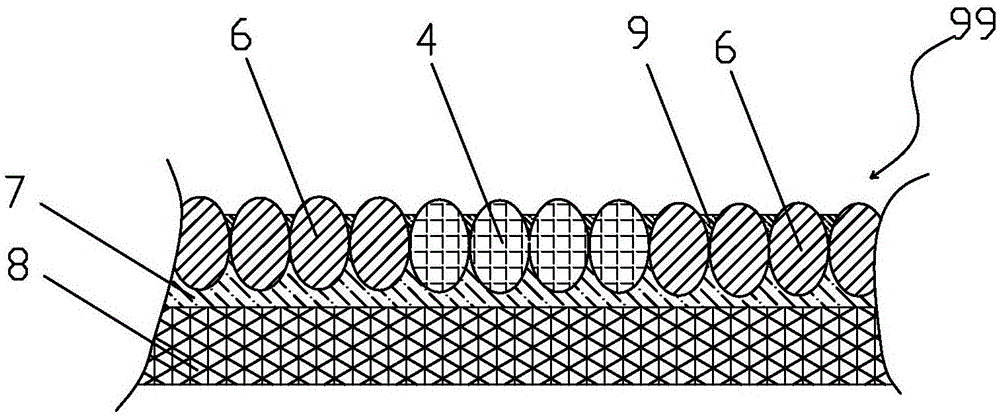

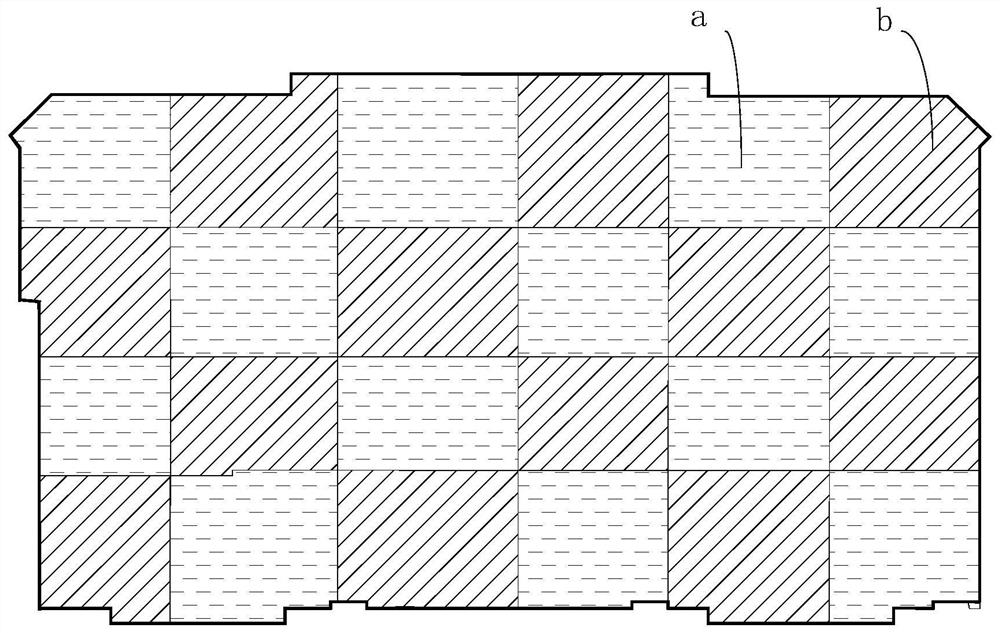

Light energy-conservation large-module combined exterior wall and method of manufacturing the same

The invention relates to a light energy-saving large module combined-type external wall body and a preparation method thereof. The wall body board is divided into two blocks for manufacture; a technical column is added in the middle; the 10 mm that depth minus width is the clearance for wall body installation and alignment; the total thickness of the wall body is 250 mm; the wall body is filled with light thermal insulating mortar; the external wall body is formed by a strengthening surface layer of two external wall surfaces, a double-layer thermal insulation board nested on the inner side of the surface layer, and a layer of cavity left in the middle; and a steel mesh is arranged in the strengthening surface layer of the two external wall surfaces, and is positioned on the surface layer by a retaining frame. The external wall body and the preparation method fully use the air layer, enhance the thermal insulation effect, save the heat insulating material, and prevent the phenomenon of rainwater infiltration in the wall body due to the cracks of the external wall. The air chamber in the thermal insulation board accounts for 30 percent of the sectional area of the thermal insulation board; the material can be saved by 30 percent by using the polystyrene foam as the heat insulating material; and the material can be saved by 20 percent by using the plastic board as the heat insulating material.

Owner:韩重博 +2

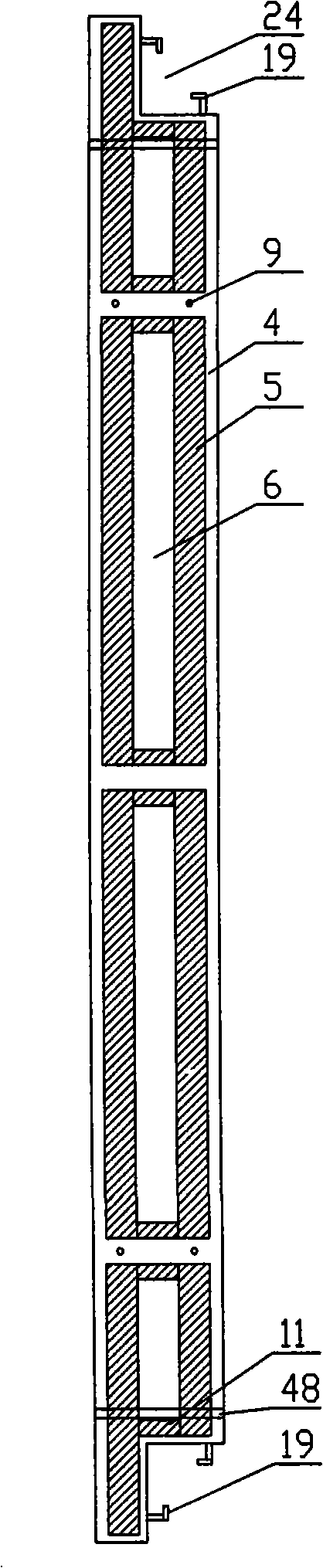

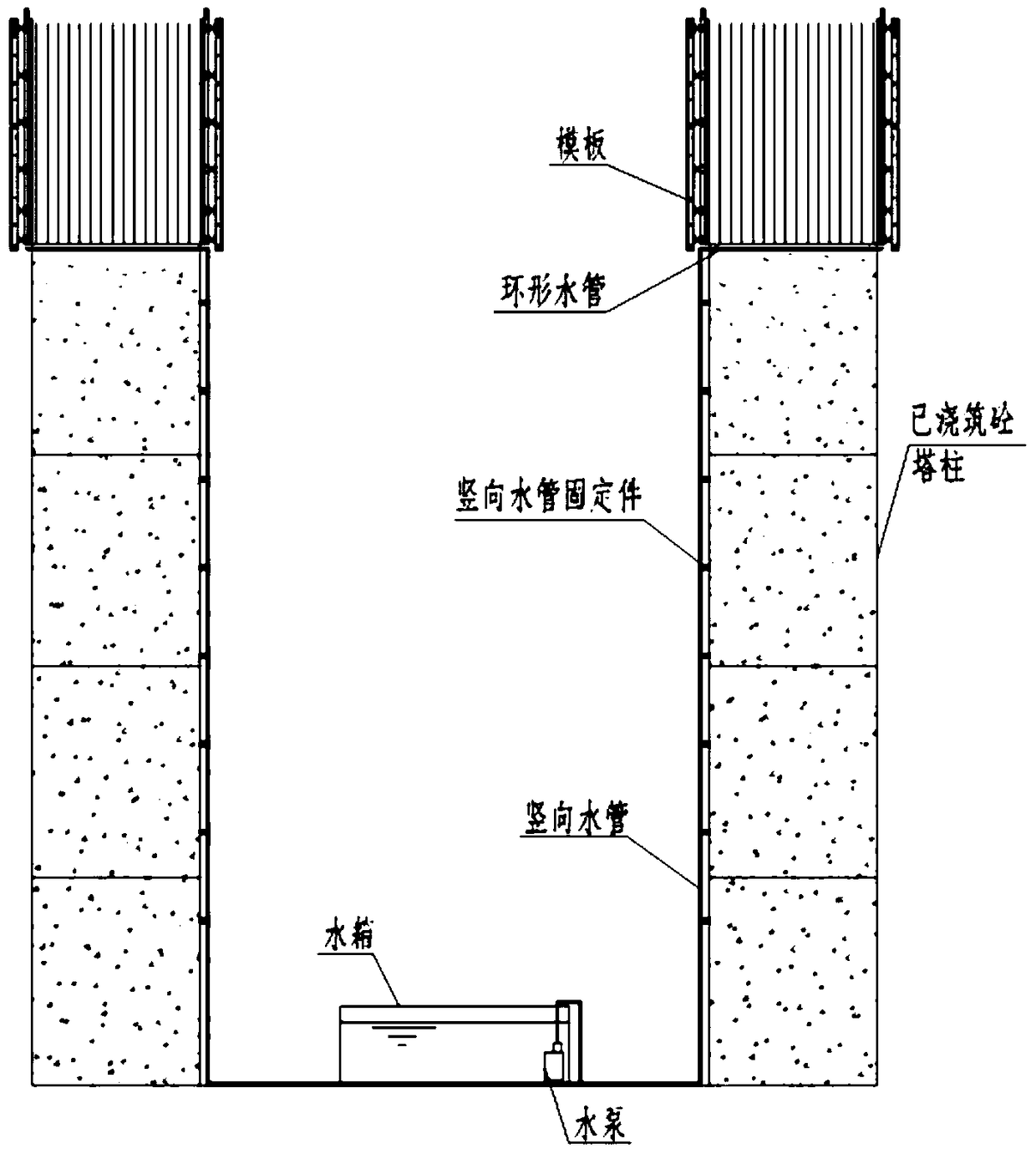

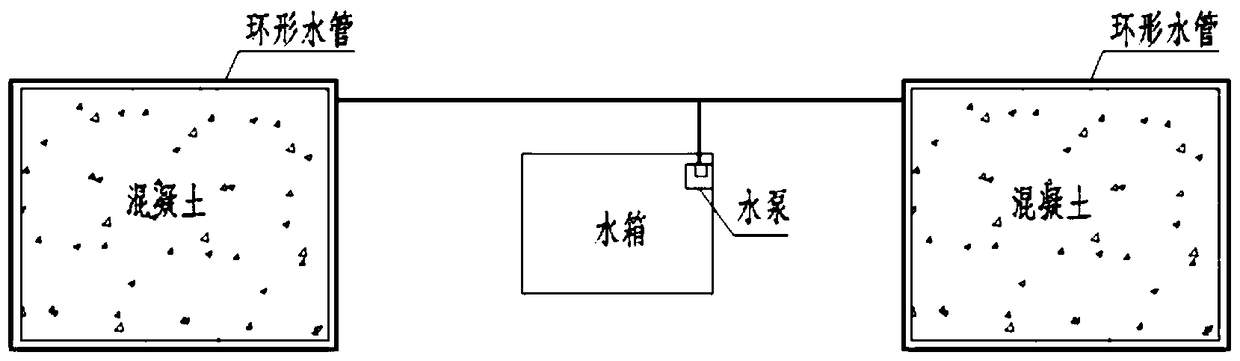

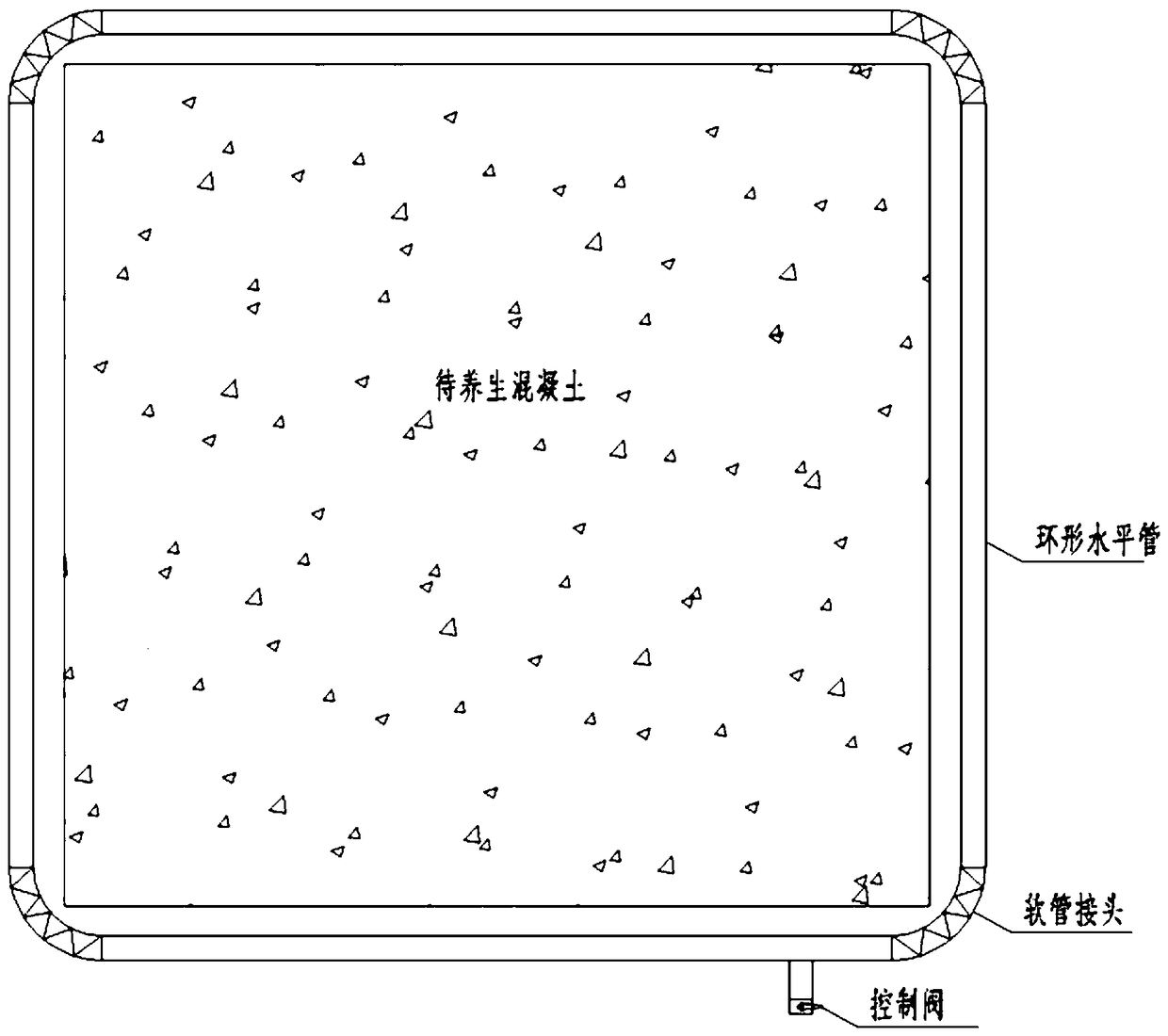

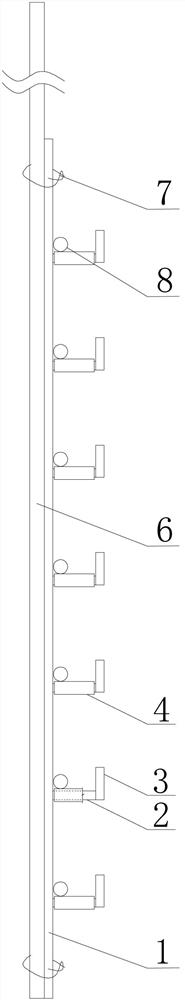

Simple high-pier tower column concrete side face maintenance construction method

ActiveCN108342986AQuality assuranceAchieve health goalsBridge erection/assemblyBridge materialsThermal insulationEngineering

The invention provides a simple high-pier tower column concrete side face maintenance construction method. The method is characterized in that a simple maintenance water pipeline system is arranged, maintenance water is pumped to tower tops through a high-lift water pump, horizontal annular maintenance water pipes are arranged on the periphery of concrete on the top face of each tower column, a water outlet with the diameter of 8 mm is formed in each annular water pipe every 35 cm, and the annular maintenance water pipes are suspended below formworks through arranged simple lifting rings. 7-mminflaming retarding thermal insulation boards with tinfoil and a geotechnical cloth combined material are adopted as moisture preservation maintenance films on the side faces of the to-be-maintainedconcrete, the maintenance films are suspended below the formworks, simple reverse press devices are arranged on the backs of the formworks and revelry press and tighten the maintenance films to the faces of the concrete, the water pump is started, the maintenance films are wet by the maintenance water through the annular maintenance water pipes, and a concrete maintenance purpose is achieved.

Owner:四川路桥华东建设有限责任公司

Prefabricating and mounting method for pebble-pattern prefabricated slab

ActiveCN105088914APavement quality is stableGuaranteed accurate textureSingle unit pavingsSidewalk pavingsEngineeringCement paste

The invention discloses a prefabricating and mounting method for a pebble-pattern prefabricated slab. The method comprises the steps that a bottom plate and a prefabricated frame with the area not larger than 1m<2> are made; graph paper is printed and is fixed to the bottom plate; the prefabricated frame is mounted on the bottom plate and surrounds the graph paper; a figure river sand layer is laid on graph paper figures; figure pebbles are laid on the figure river sand layer; a bottom river sand layer is laid on the non-figure position of the graph paper; bottom pebbles are laid on the bottom river sand layer; unqualified pebbles are replaced; a cement paste sticking layer is laid on the pebble layer; a concrete cushion is laid on the cement paste sticking layer; after the concrete cushion is cured, the prefabricated frame is removed, and 180-degree turning is carried out; the figure river sand layer and the bottom river sand layer are swept out; a cement mortar layer is brushed on the pebble layer; the pebble layer protrudes out of the cement mortar layer by 8mm to 10mm; a concrete base layer is laid; the cement mortar layer is laid on the concrete base layer; and multiple pebble-pattern prefabricated slabs are put on the cement mortar layer; and the pebble-pattern prefabricated slabs are jointed. The site operation efficiency is high, and the quality is stable.

Owner:PALM ECO TOWN DEV CO LTD

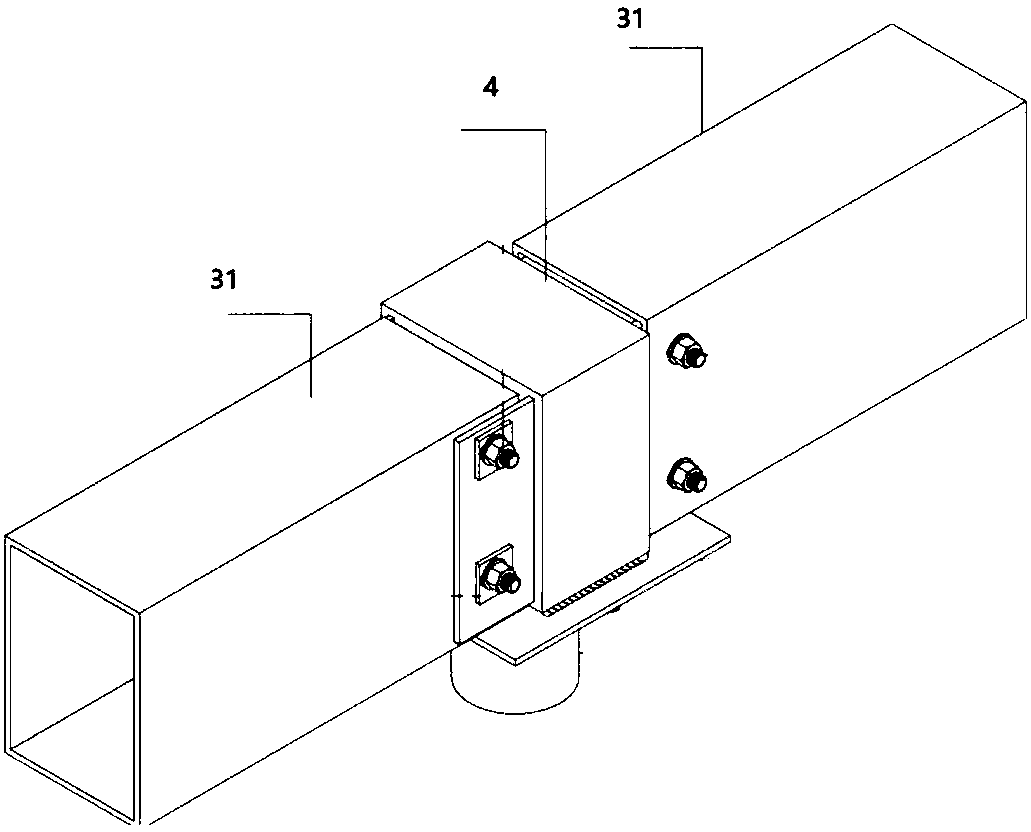

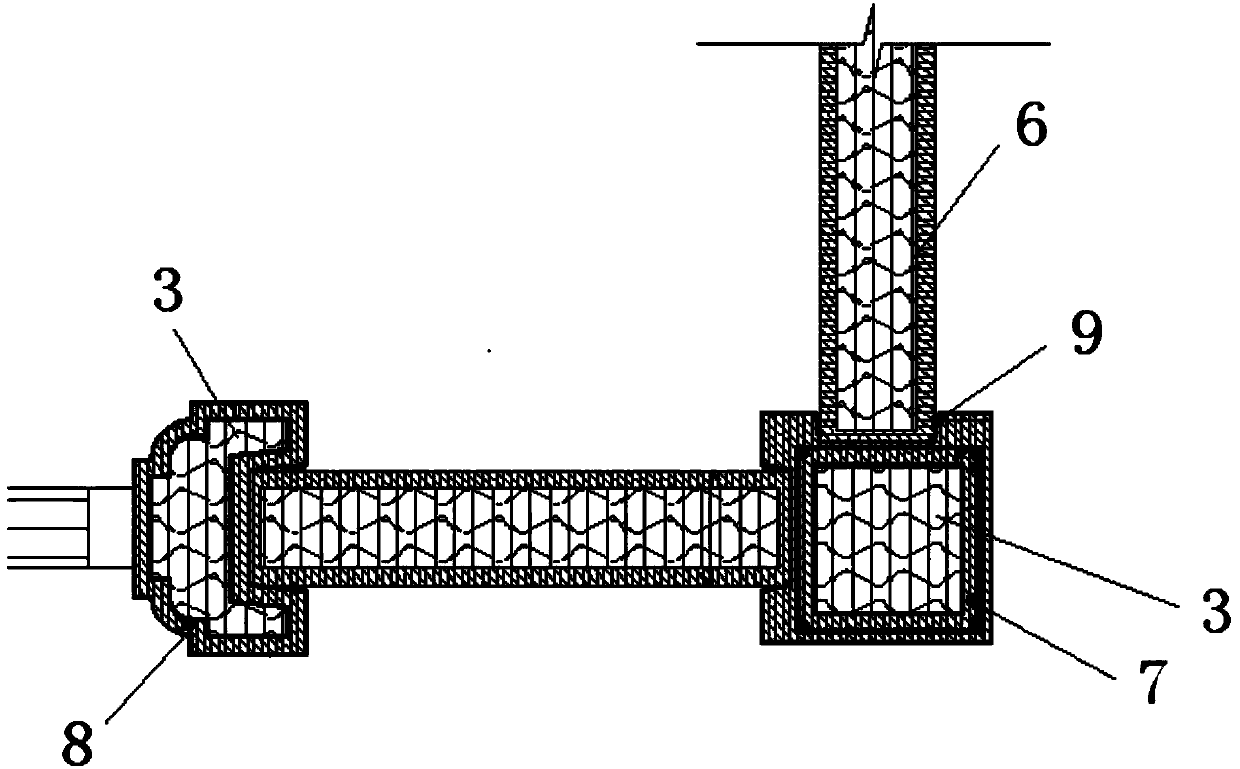

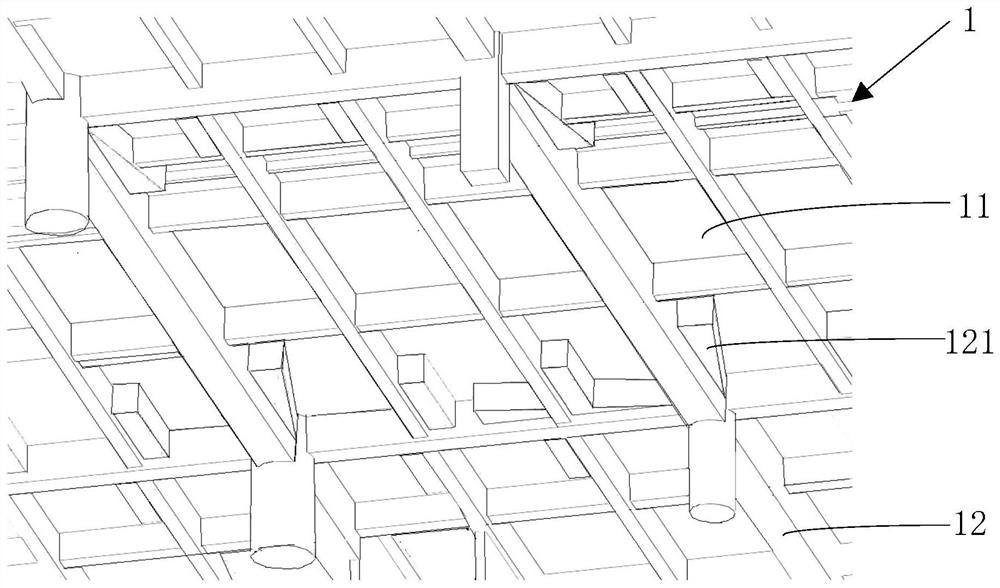

Safety and wind-resistant metal roofing structure system and installation technology thereof

PendingCN108166659AEffective immobilizationEffective limitBuilding roofsRoof covering using slabs/sheetsEngineeringTemperature difference

The invention discloses a safety and wind-resistant metal roofing structure system including a roofing system, a main steel structure and a roof decoration structure. The roofing system is connected with the main steel structure by sandalwood strips, wherein the sandalwood strips include main sandalwood strips and auxiliary sandalwood strips. The main sandalwood strips are arranged on the upper portion of the main steel structure, and are connected with the main steel structure by connectors. Sleeved pipes are arranged on the main sandalwood strips, and long circular holes are formed in the main sandalwood strips. The sleeved pipes penetrate the long circular holes, and are connected with the main sandalwood strips by bolt assemblies. The sleeved pipes and the main sandalwood strips are positioned by lug plates. Cushion plates are arranged between the bolt assemblies and the long circular holes, and the sleeved pipes are connected with the main sandalwood strips by connecting steel plates. The auxiliary sandalwood strips are connected with the main sandalwood strips by connecting plates. The roof decoration structure is arranged on the upper portion of the roofing system, and is connected with the roofing system by U-shaped adapters. The safety and wind-resistant metal roofing structure system is provided with the sleeved pipes and the lug plates, and the connection between thesleeved pipes and the main sandalwood strips is realized by the bolt assemblies penetrate through the long circular holes, so that the problem of flexibility of the sandalwood strips caused by temperature difference is solved well.

Owner:SHANDONG YABAITE SCI & TECH CO LTD

A kind of wall building material and preparation method thereof

The invention discloses a wall building material, comprising the following components in parts by weight: 50-80 parts of ceramic polishing residue, 0-30 parts of feldspar, 2-10 parts of calcined soapstone, 10-20 parts of red mud, 0-10 parts of lithium feldspar, 0-15 parts of dickite, 0.5-2 parts of silicon carbide, 1.5-3 parts of stabilizer and 40-50 parts of water. The invention also provides a preparation method of the wall building material. The method comprises the following steps: ball-milling, drying, loading into a cellar, sintering and cutting. The wall building material disclosed by the invention is light in dead load, good in anti-seismic effect, high in thermal insulation properties and good in sound insulation.

Owner:河南中传装备有限公司

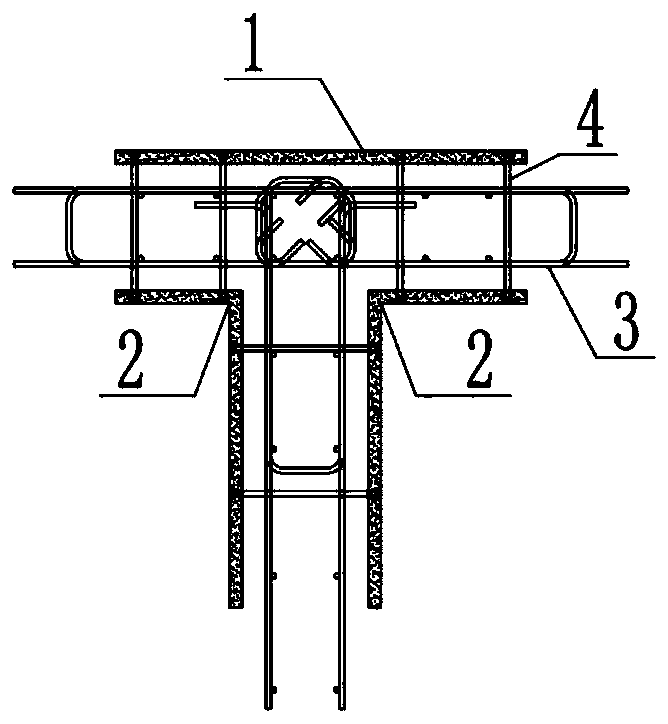

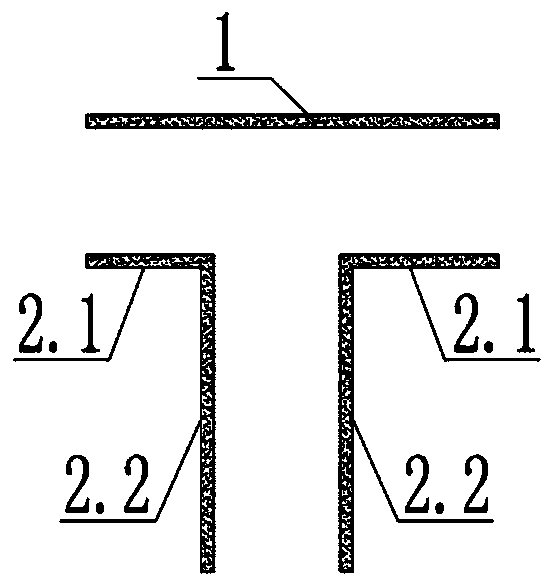

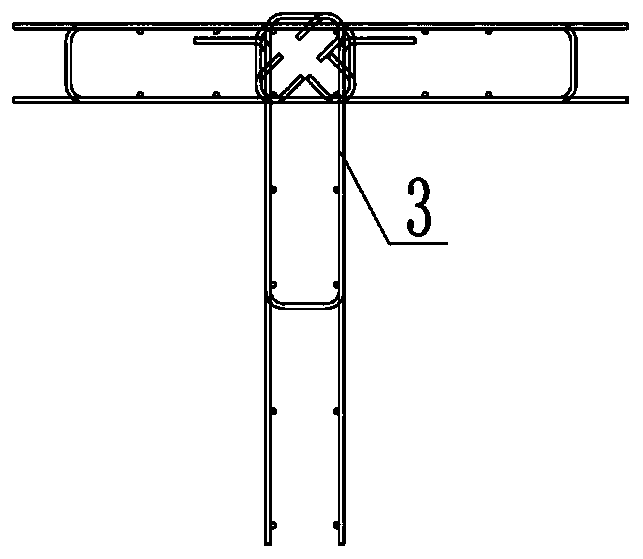

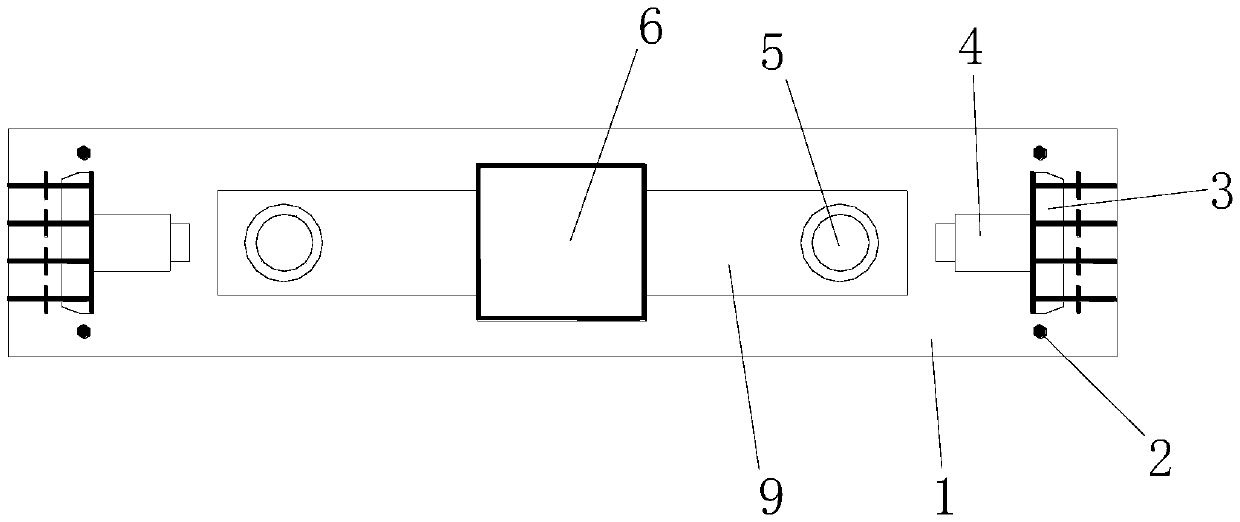

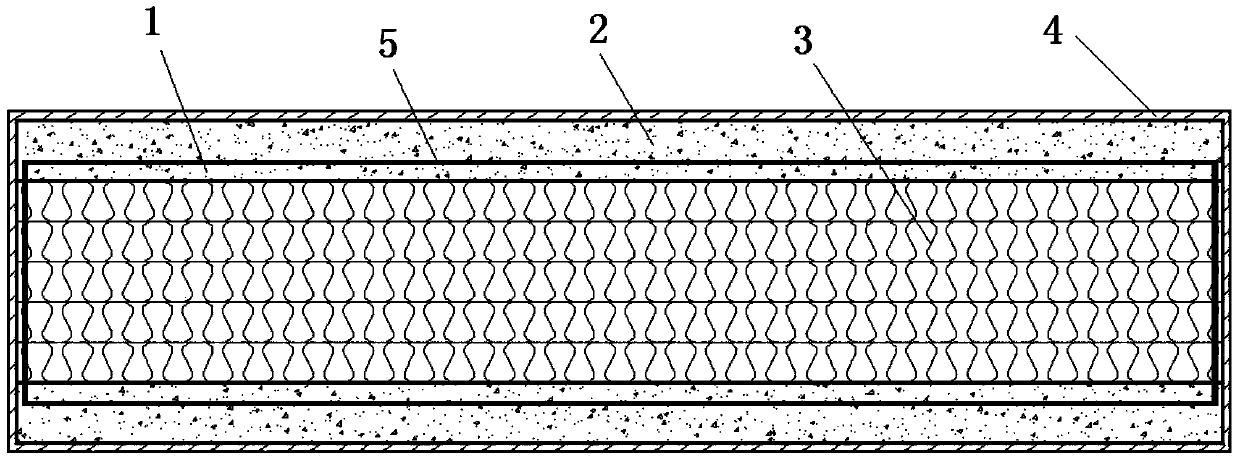

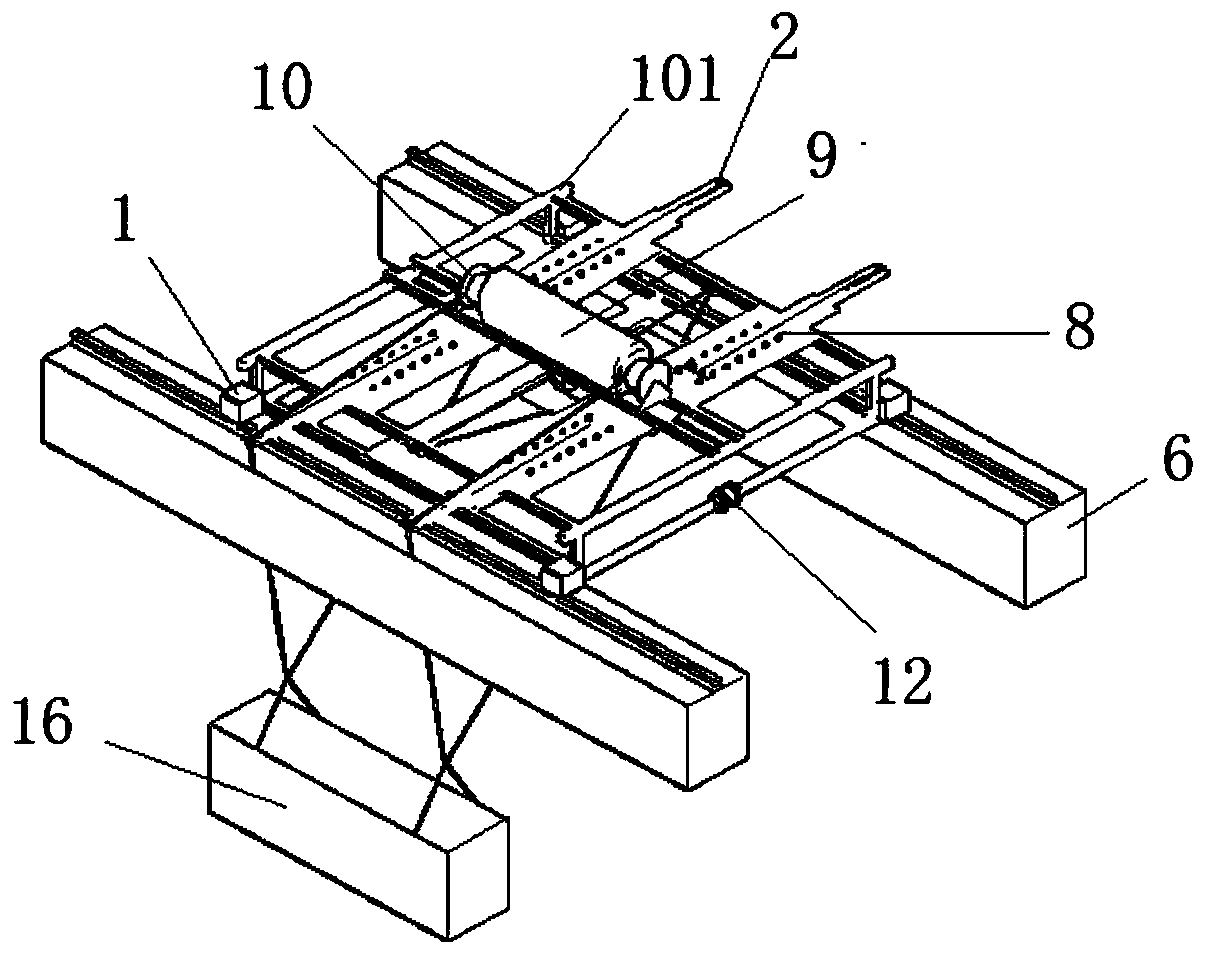

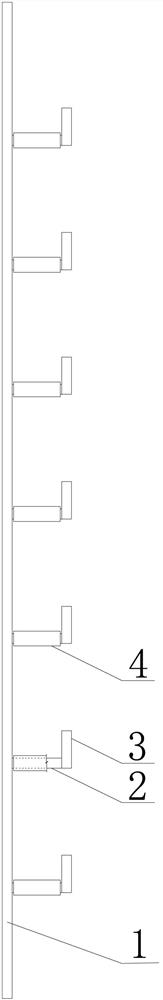

Rebar formwork integrated T-shaped wall member and production method

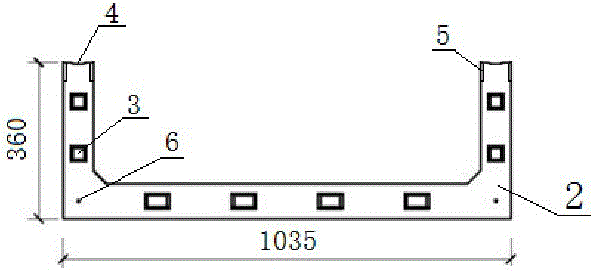

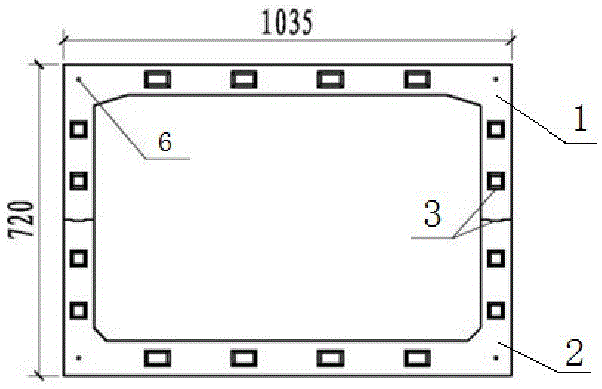

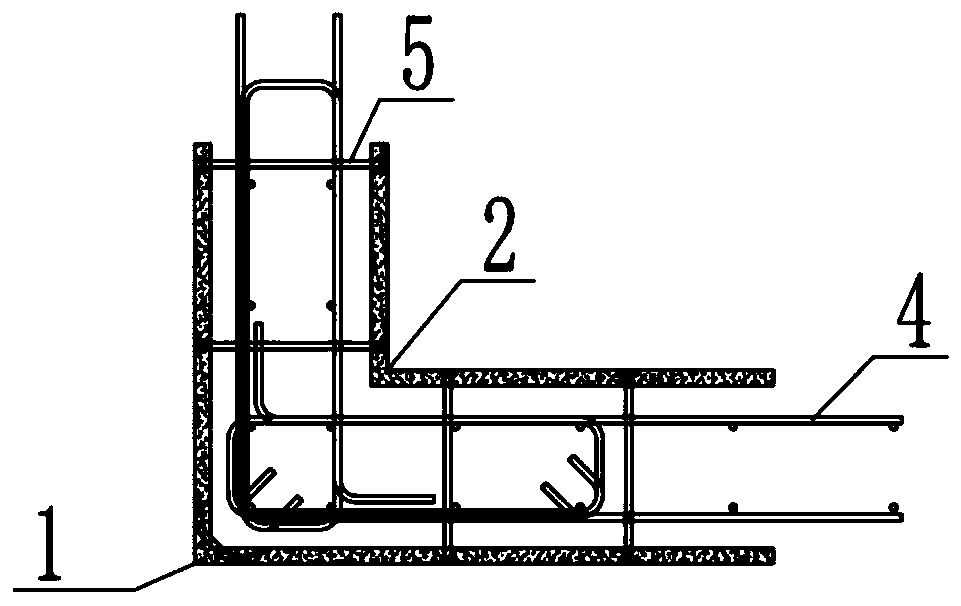

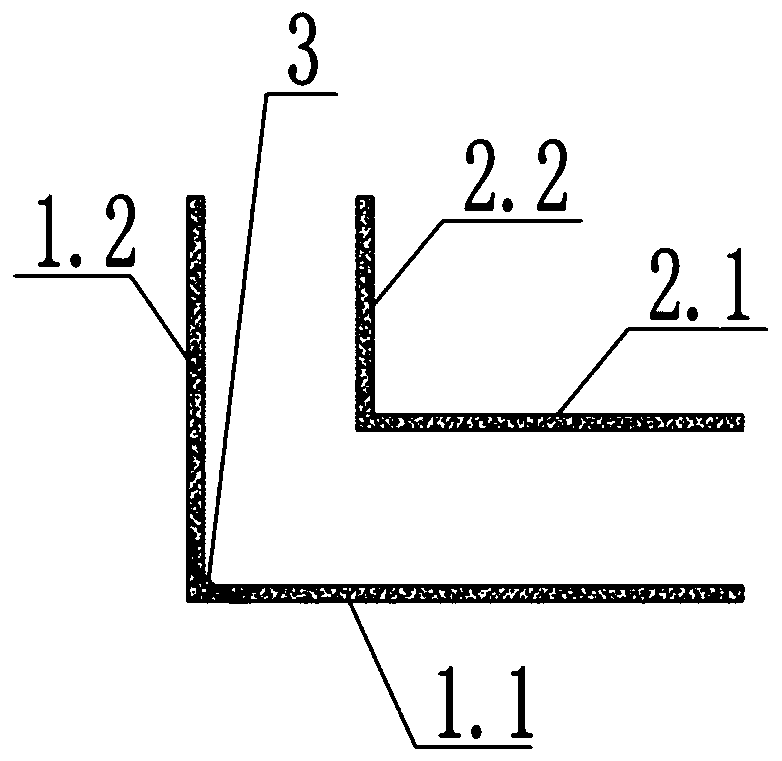

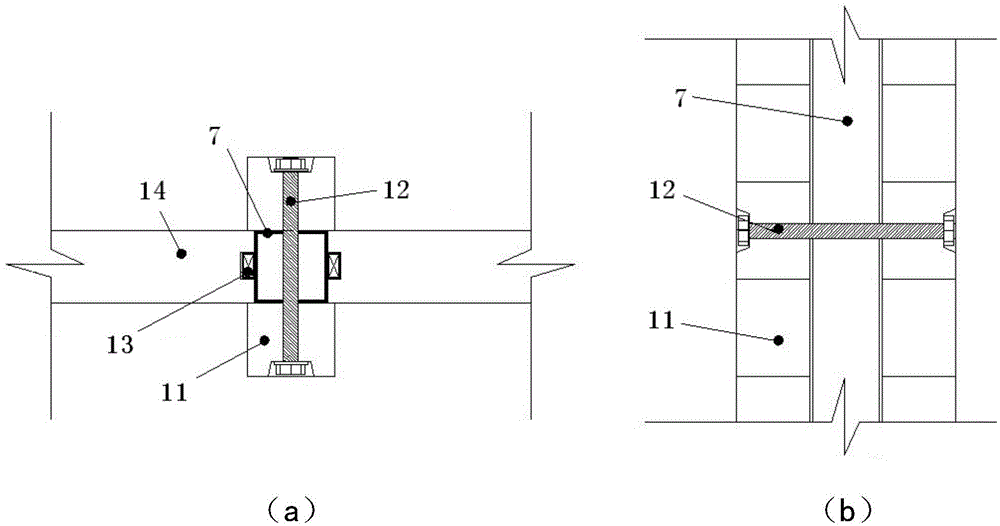

PendingCN110042958ASpeed up on-site construction progressReduce weightWallsCeramic shaping apparatusRebarShear wall

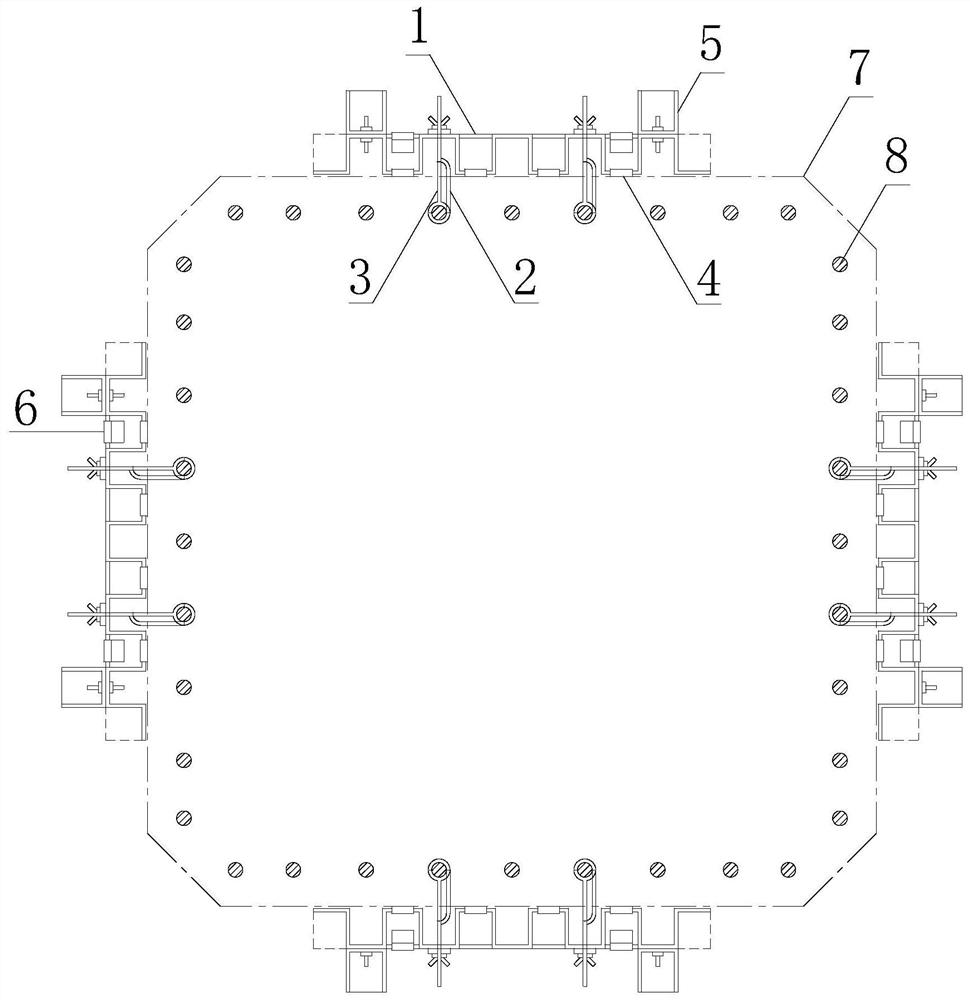

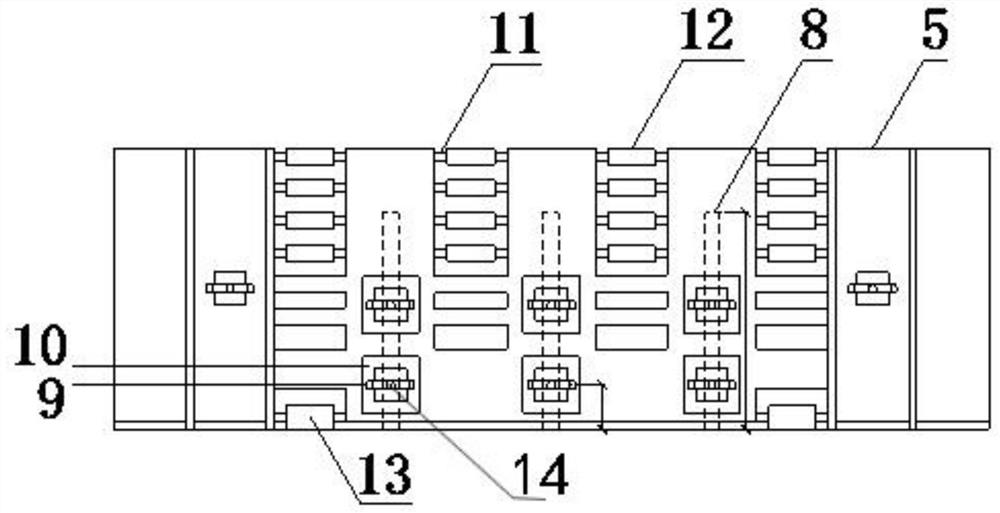

The invention discloses a rebar formwork integrated T-shaped wall member and a production method. The rebar formwork integrated T-shaped wall member comprises a linear formwork, internal corner L-shaped formworks, a T-shaped wall rebar skeleton and split connecting pieces; the internal corner L-shaped formworks are located at two internal corners of the rebar formwork integrated T-shaped wall member and are composed of first internal corner L-shaped formwork branch limbs and second internal corner L-shaped formwork branch limbs, wherein the first internal corner L-shaped formwork branch limbsare perpendicular to the second internal corner L-shaped formwork branch limbs; the first internal corner L-shaped formwork branch limbs are parallel to the linear formwork, and the two second internal corner L-shaped formwork branch limbs are parallel to each other; the T-shaped wall rebar skeleton is in a T shape; and two ends of the split connecting pieces are arranged in the two parallel formworks in a buried mode correspondingly, the middle parts of the split connecting pieces are fixed to the T-shaped wall rebar skeleton, and the linear formwork, the internal corner L-shaped formworks and the T-shaped wall rebar skeleton are enabled to form the integrated member. According to the rebar formwork integrated T-shaped wall member and the production method, rebars and formworks of an L-shaped wall in a shear wall structure are integrated, the formworks do not need to be dismantled, and the site construction progress is accelerated; and the integrated member is light in weight, convenient to install, and convenient to produce and machine.

Owner:CHINA RAILWAY CONSTR GROUP +1

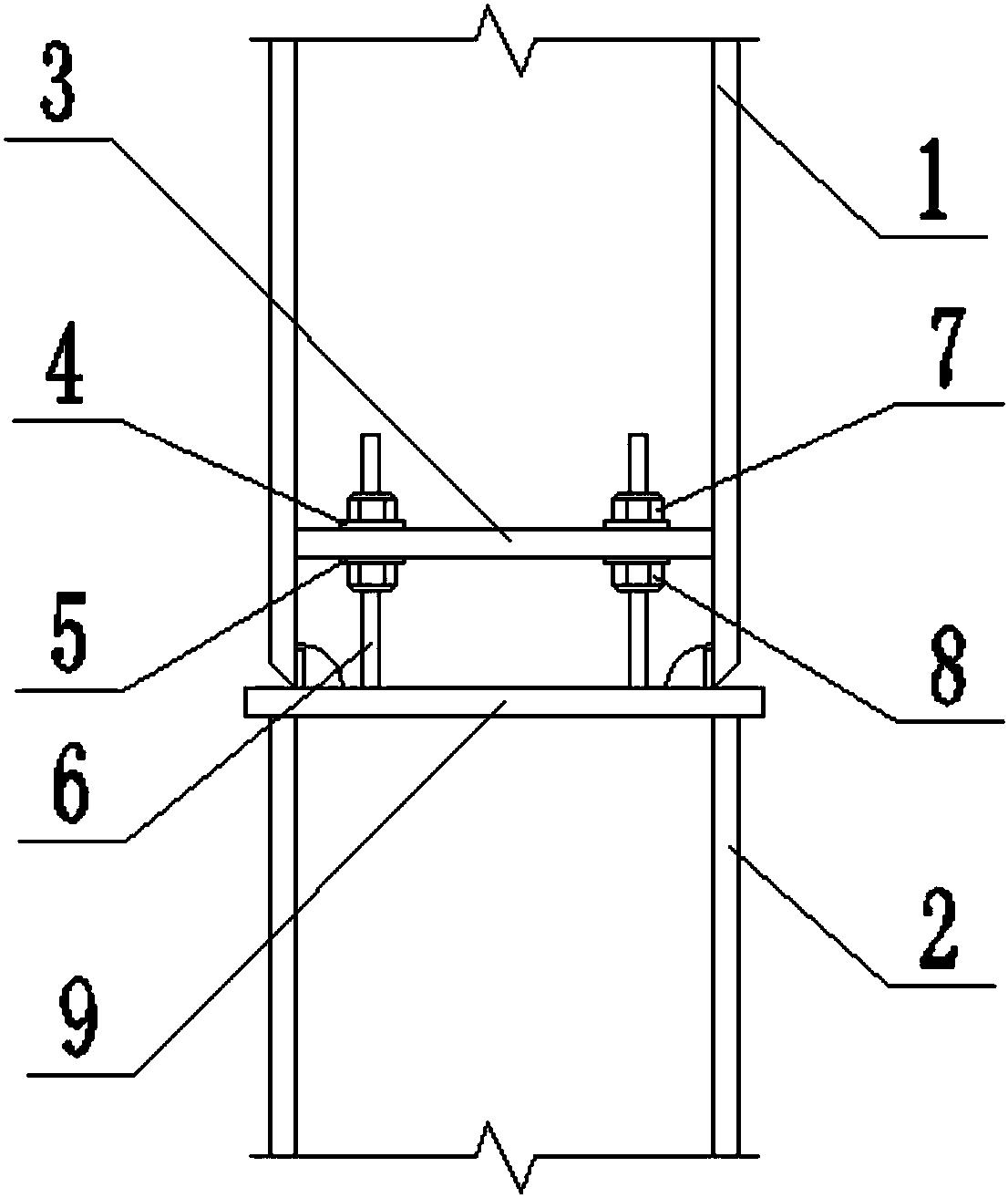

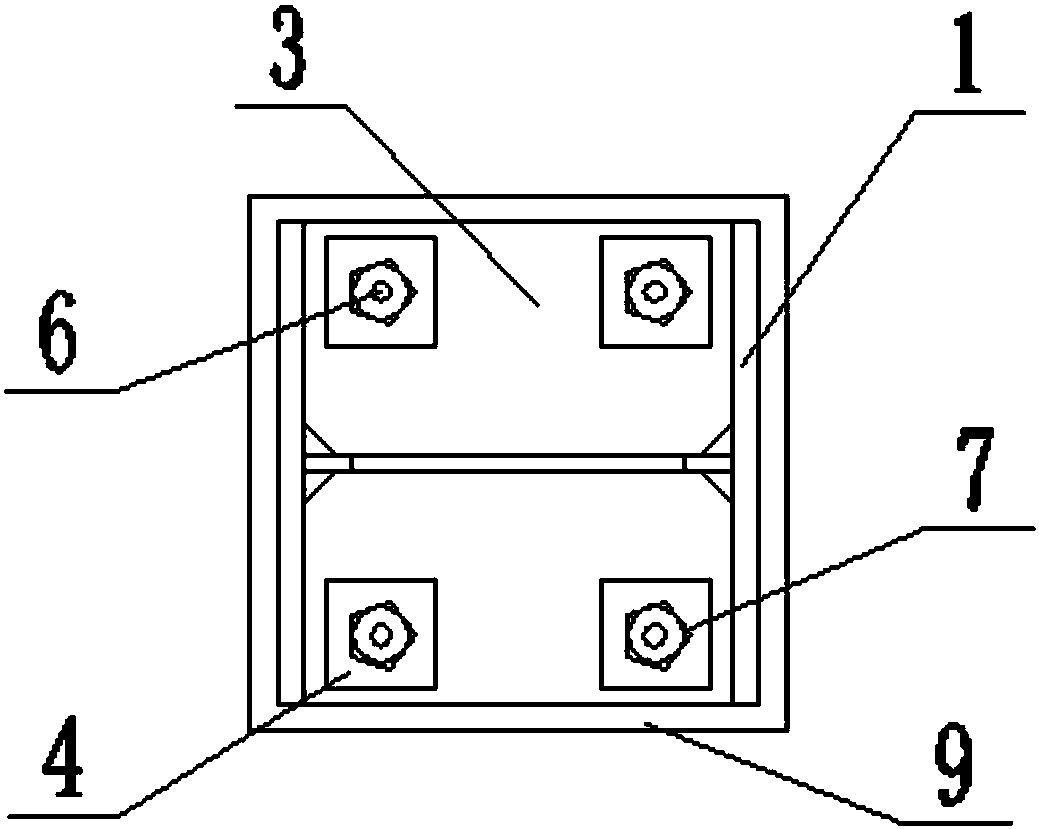

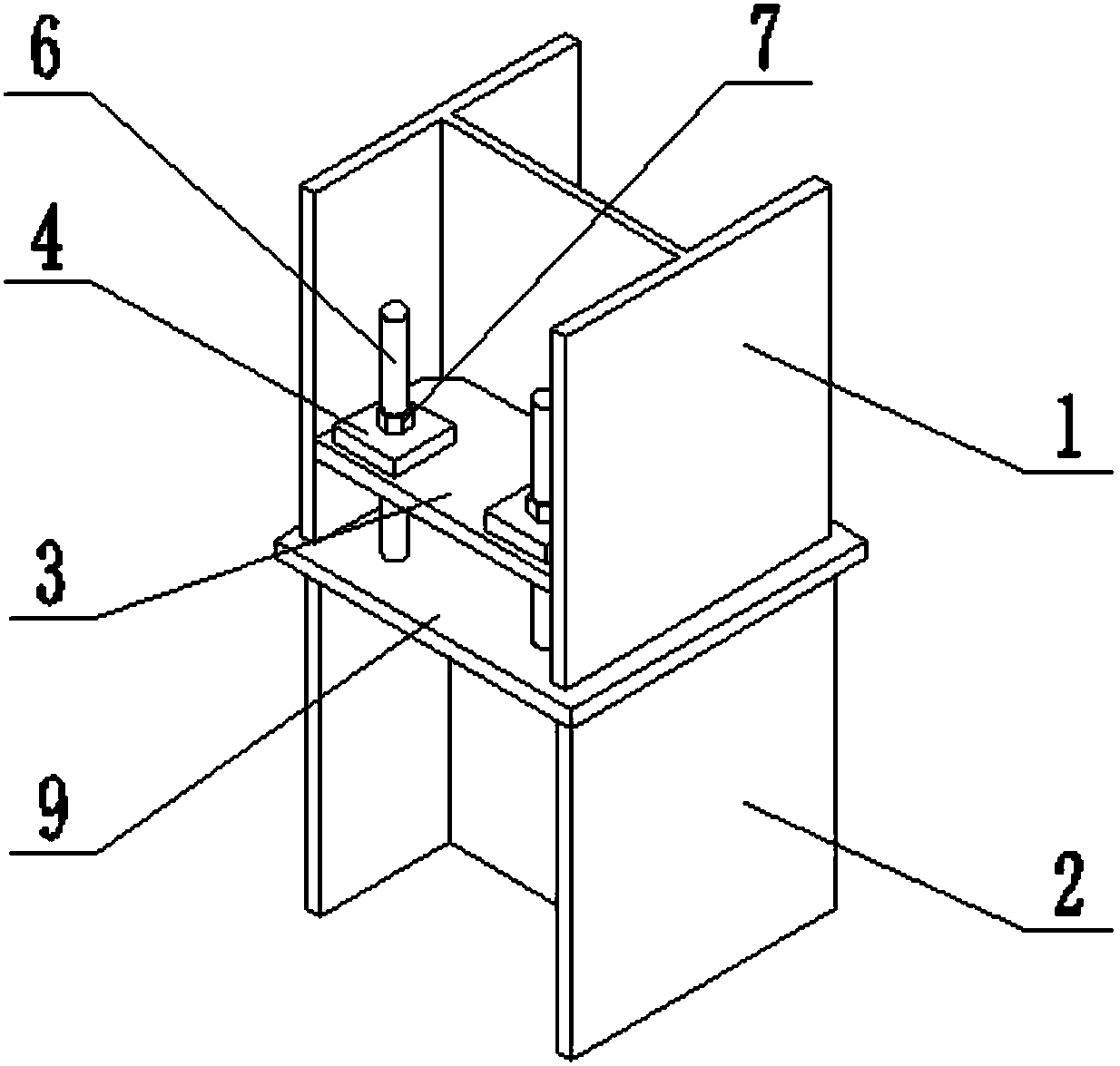

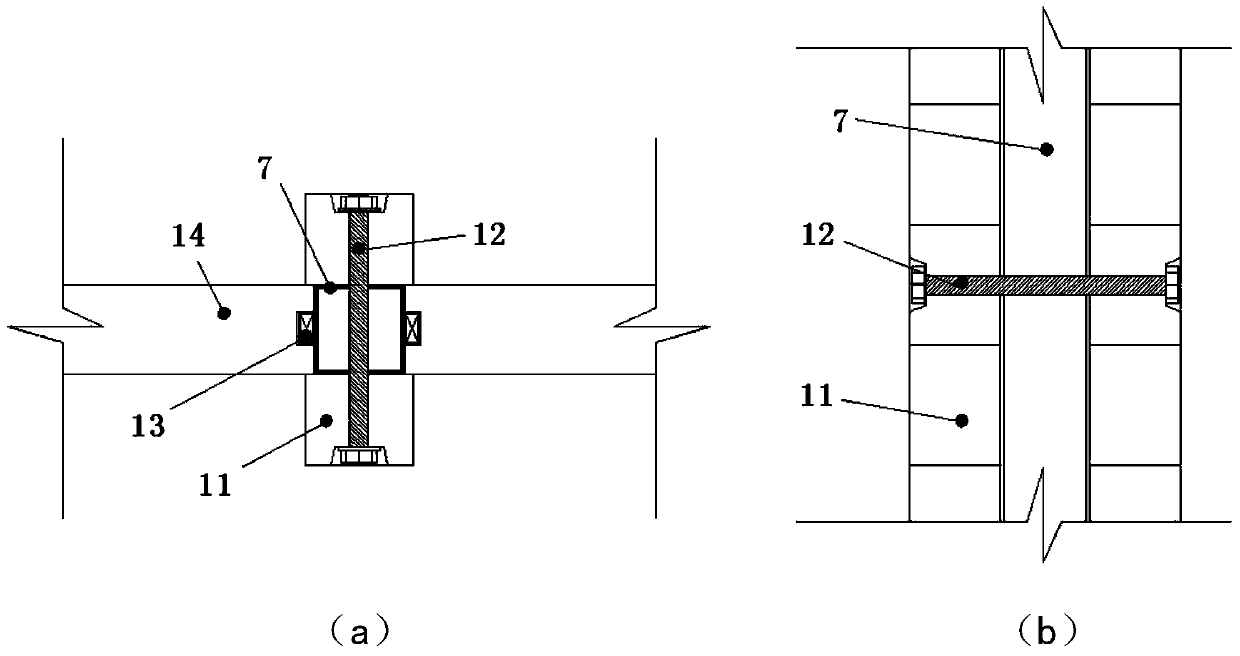

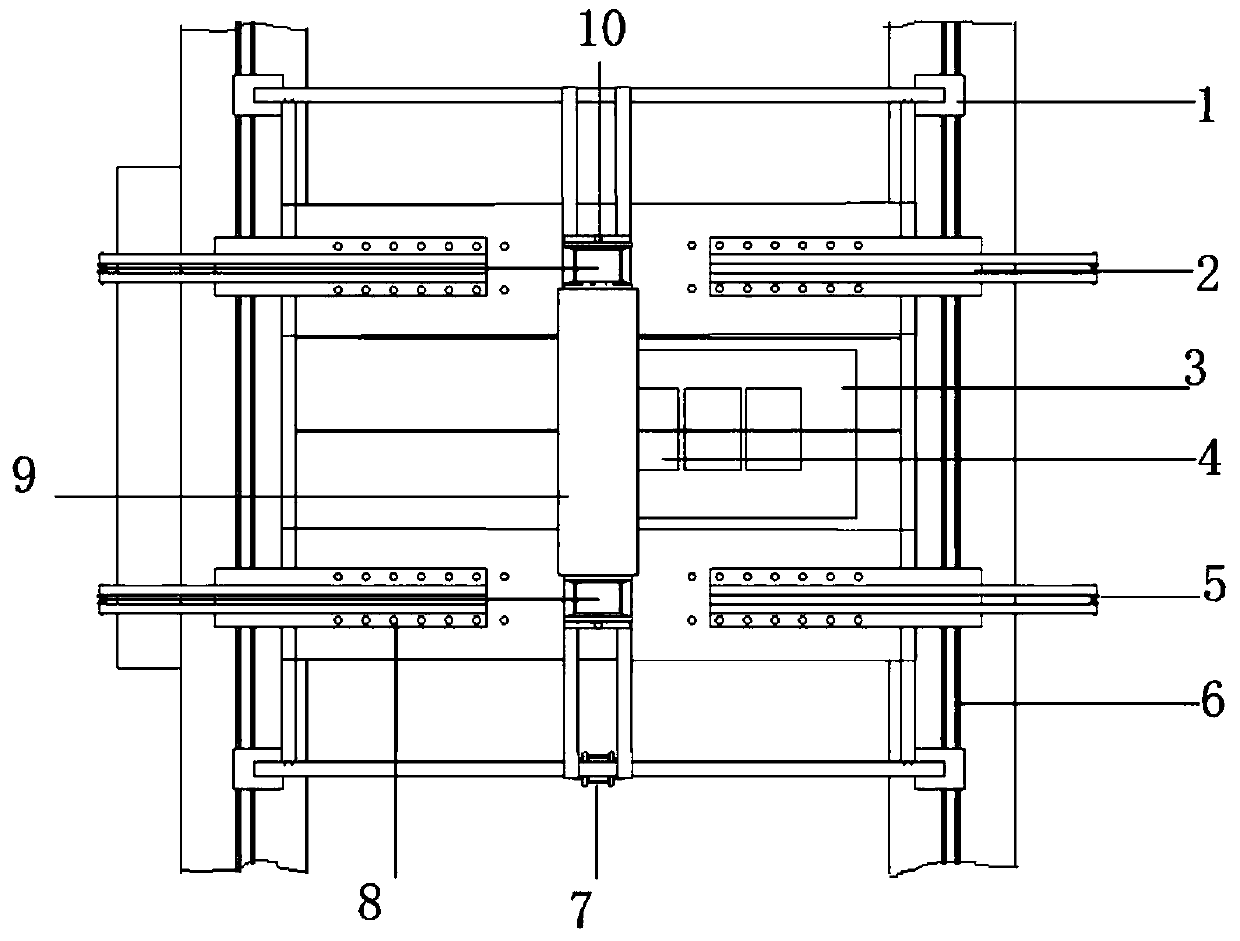

H-shaped steel column splicing device and construction method thereof

The invention provides an H-shaped steel column splicing device and a construction method thereof, relates to the technical field of construction engineering, and solves the technical problem that a conventional H-shaped steel column splicing device cannot meet the demand for the rapid construction of a steel structure. The H-shaped steel column splicing device provided by the invention is characterized in that two horizontal connecting plates are correspondingly arranged between flange plates of upper segmented columns and at the lower parts of two sides of a web plate; four positioning holesare symmetrically formed in the two horizontal connecting plates correspondingly along the length direction; upper backing plates are arranged above the four positioning holes; lower backing plates are arranged below the positioning holes; through holes corresponding to the positioning holes are formed in the centers of both the upper backing plates and the lower backing plates; a top plate matched with one end surface of an H-shaped steel column is arranged on the top surface of the lower segmented column; and four long bolts are fixed at the positions, corresponding to the four positioningholes in the horizontal connecting plates, of the top surface of the top plate, as well as connected with four lower adjusting nuts, the lower backing plates, the horizontal connecting plates, the upper backing plates and upper adjusting nuts in sequence. The H-shaped steel column splicing device is applied to the on-site splicing of the H-shaped steel column, and has the advantages that the structure is simple, the positioning is correct, and the mounting is convenient.

Owner:山西天巨美虹钢构有限公司

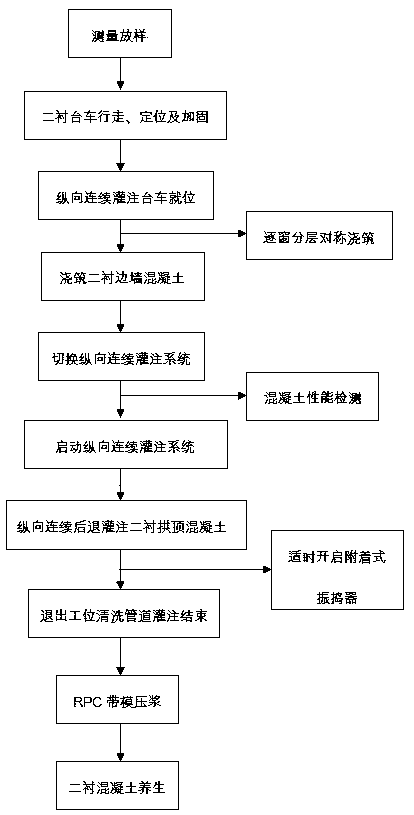

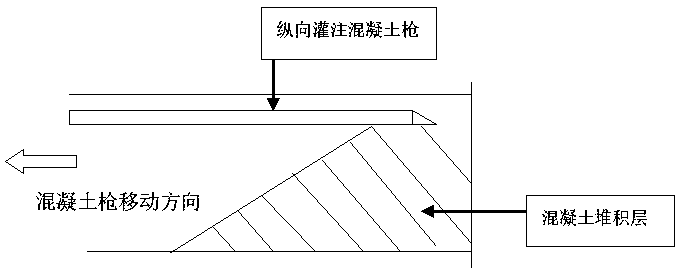

Concrete longitudinally-continuous pouring construction method for tunnel secondary lining vault

ActiveCN110700854AReduce grouting costsReduce construction costsUnderground chambersTunnel liningArchitectural engineeringPipe

The invention belongs to the technical field of construction of tunnel engineering, and particularly relates to a concrete longitudinally-continuous pouring construction method for a tunnel secondarylining vault. The lining quality problems that the arch part concrete cannot be densely packed, the secondary lining is insufficient in thickness, and the back is empty and not dense are solved; the method comprises the following steps that S100, measurement lofting is conducted; S200, a secondary lining trolley is travelled, positioned and reinforced; and S300, a longitudinally-continuous pouringtrolley is in place; S400, secondary lining side wall concrete is poured; and S500, after window-by-window layering pouring and vibrating is finished on the part of the secondary lining side wall concrete, a concrete pump pipe connector is replaced and connected with the longitudinally-continuous pouring trolley, performance detection is conducted on the field secondary lining arch concrete, andthe in-formwork concrete slump degree is required to be controlled to be 170 mm-190 mm; S600, a concrete conveying pump is started; S700, the secondary lining arch concrete is longitudinally and continuously poured in a retreating mode; S800, a station exits and a pipeline is cleaned, and the pouring is ended; and S900, RPC formwork grouting is conducted.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

One-way all-cantilever steel truss arch bridge correcting device and use method thereof

PendingCN108035259ASimple structureEasy to operateBridge erection/assemblyArch-type bridgeArchitectural engineeringArch bridge

The invention discloses a one-way all-cantilever steel truss arch bridge correcting device and a use method. The correcting device comprises a base. The two ends of the base are each provided with a counter-force base for transversely limiting a steel beam in the construction process and providing stand counter-force during transverse correcting. The two counter-force bases are each connected witha horizontal jack I. The two jacks I are oppositely arranged and used for transverse correcting adjustment of the steel beam in the construction process. A temporary stand is arranged in the middle of the base and used for temporarily supporting a force point of the steel beam. A vertical jack II is arranged between the temporary stand and each jack I. The force exerting end of each jack II facesupward, and the jacks II are used for vertical correcting adjustment of the steel beam in the construction process.

Owner:SHANDONG UNIV +1

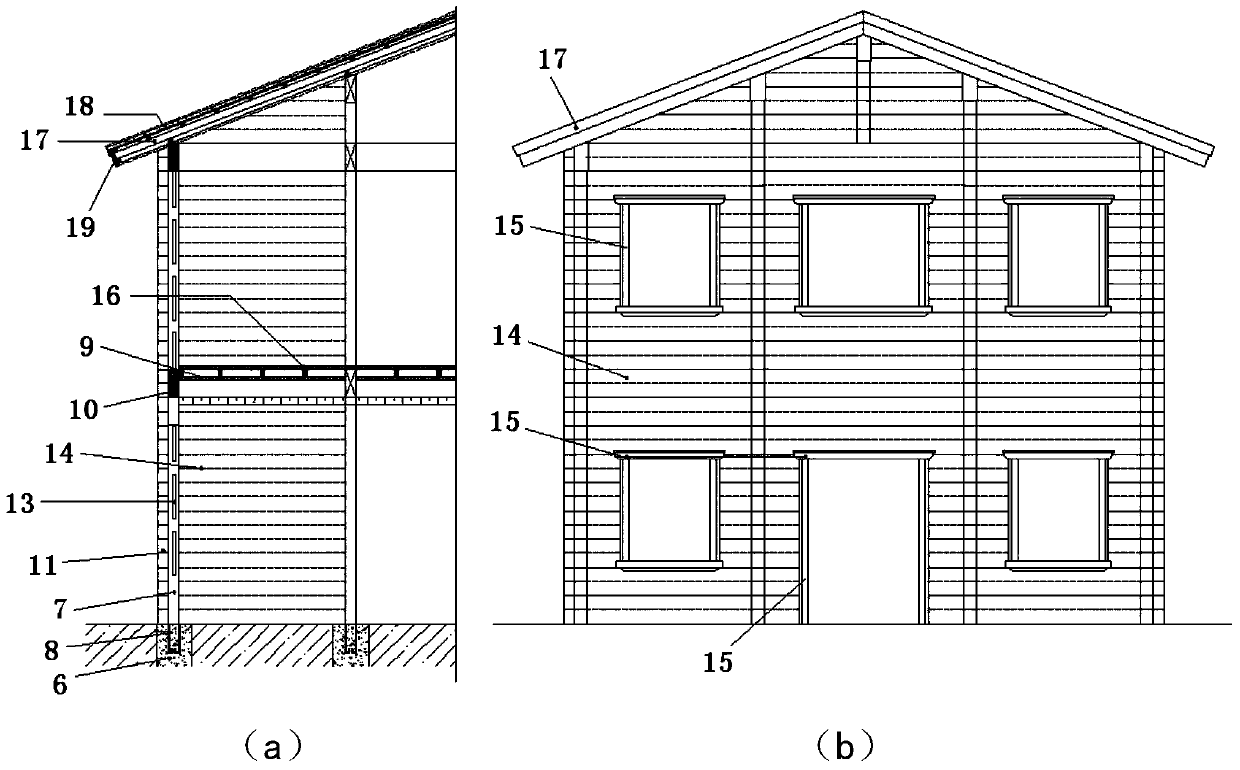

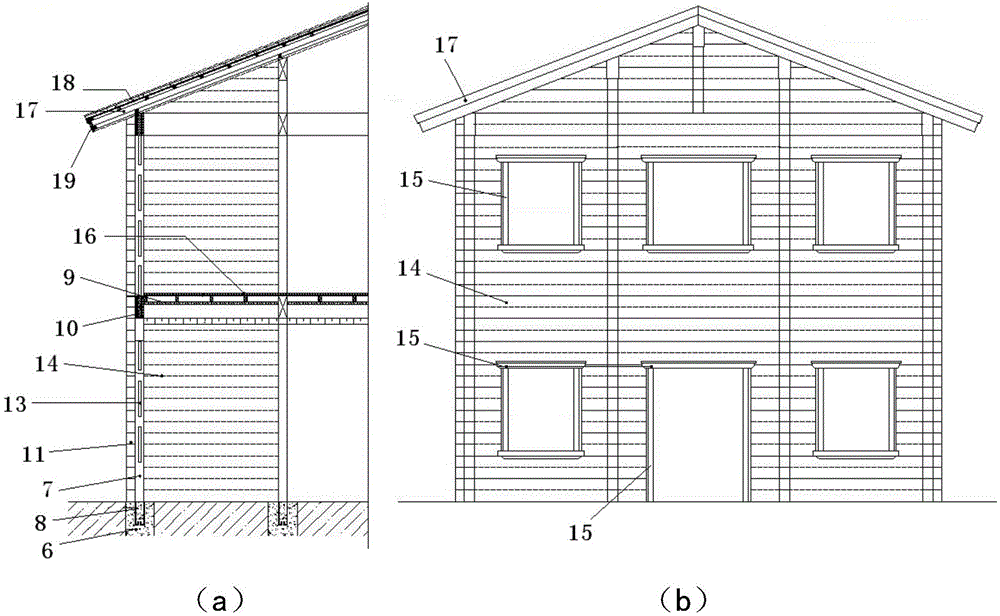

Building method of imitation wood villa with steel structural framework

InactiveCN103696585AReduce engineering costsLow costBuilding componentsDwelling buildingWood veneerKeel

The invention relates to a building method of an imitation wood villa with a steel structural framework. The method includes the steps of 1, reserving steel-plate embedded parts according the number and position of steel columns; 2, connecting the middle and top end of the steel columns to ring beams in a second light steel keel floor plate and a steel structural framework respectively; 3, mounting decorative columns inside and outside the steel columns; 4, anchoring a plurality of square steel tubes to two sides, with no decorative columns, of the steel columns, and inserting and fixing GRC imitation wood wall veneers into the square steel tubes; 5, mounting door jambs and window frames; 6, anchoring inorganic-plate base linings onto the second light steel keel floor plate, and laying floor material; 7, welding or anchoring a roof to the ring beams; 8, subjecting exposed connections of the GRC simulation wood veneers to caulking and the like, and facing with varnish to complete construction of the villa. Through the application of the method, the problems that the traditional building method causes high cost, low speed, failure of fire proofing and the like are solved; the building method is widely applicable to the building field.

Owner:韩杰

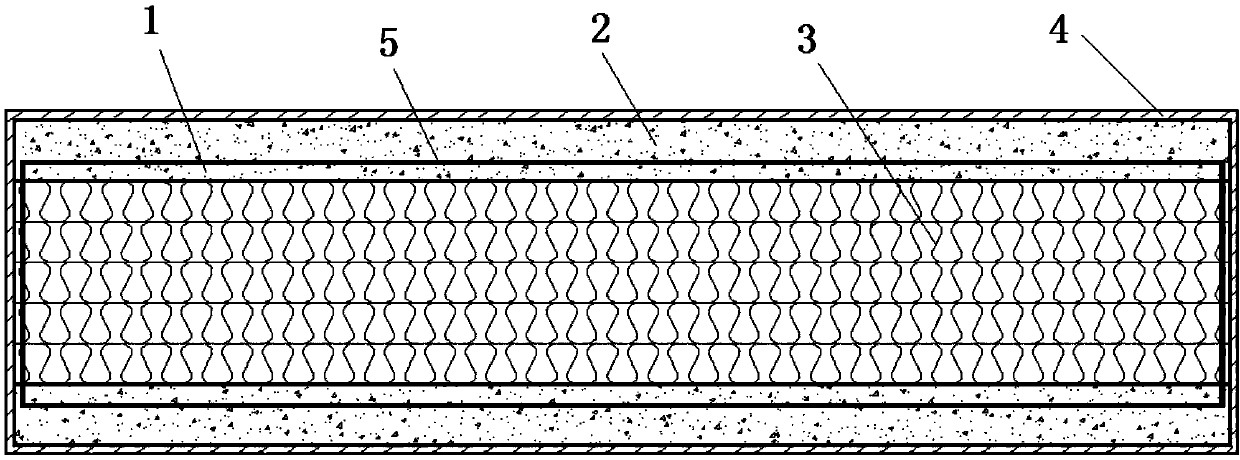

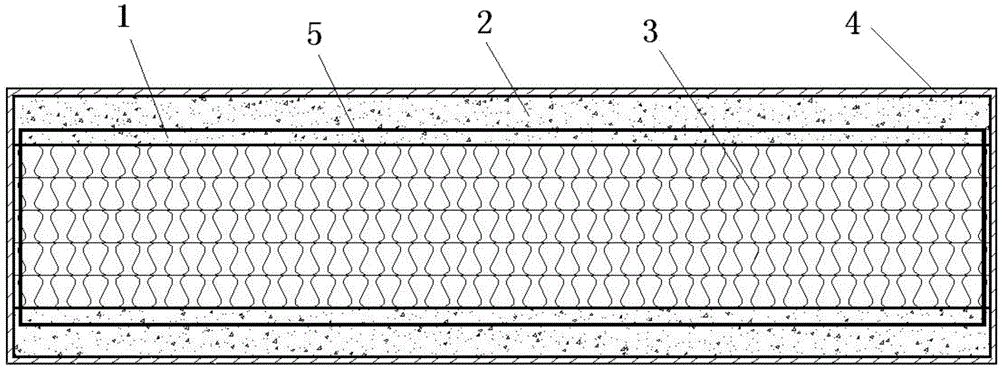

Waterproof and heat-preservation integrated plate of building outer wall and construction method of waterproof and heat-preservation integrated plate

InactiveCN109356296ARich in colorRich textureHeat proofingBuilding insulationsWater leakageFixed frame

The invention provides a waterproof and heat-preservation integrated plate of a building outer wall. The waterproof and heat-preservation integrated plate of the building outer wall is arranged on theouter side wall of the building outer wall; a levelling layer is smeared between the waterproof and heat-preservation integrated plate and the building outer wall; the waterproof and heat-preservation integrated plate comprises a heat-preservation plate and decoration plates; a waterproof layer is arranged between the heat-preservation plate and the decoration plates; reserved bolt holes are formed in the surfaces of the four side walls of the decoration plates correspondingly; a fixing frame is arranged between the side walls of the adjacent decoration plates; the longer edge of the fixing frame serves as the side edge to be attached to the decoration plates; and the shorter edge of the fixing frame serve as the bottom edge to be attached to the levelling layer. The waterproof and heat-preservation integrated plate is simple in structure and convenient to construct, the construction progress of the building outer wall is accelerated, and thus the construction cost is lowered; and meanwhile the problems that a spliced seam of an outer wall heat-preservation and waterproof plate is prone to water leakage and is gradually enlarged along with increasing of the service time are solved.

Owner:CHINA MCC17 GRP

Guide device for assembling and positioning prefabricated polygonal bridge pier and design method

PendingCN112081013AReduce weightMeet the needs of transition convenienceBridge structural detailsBridge erection/assemblyPilot holeArchitectural engineering

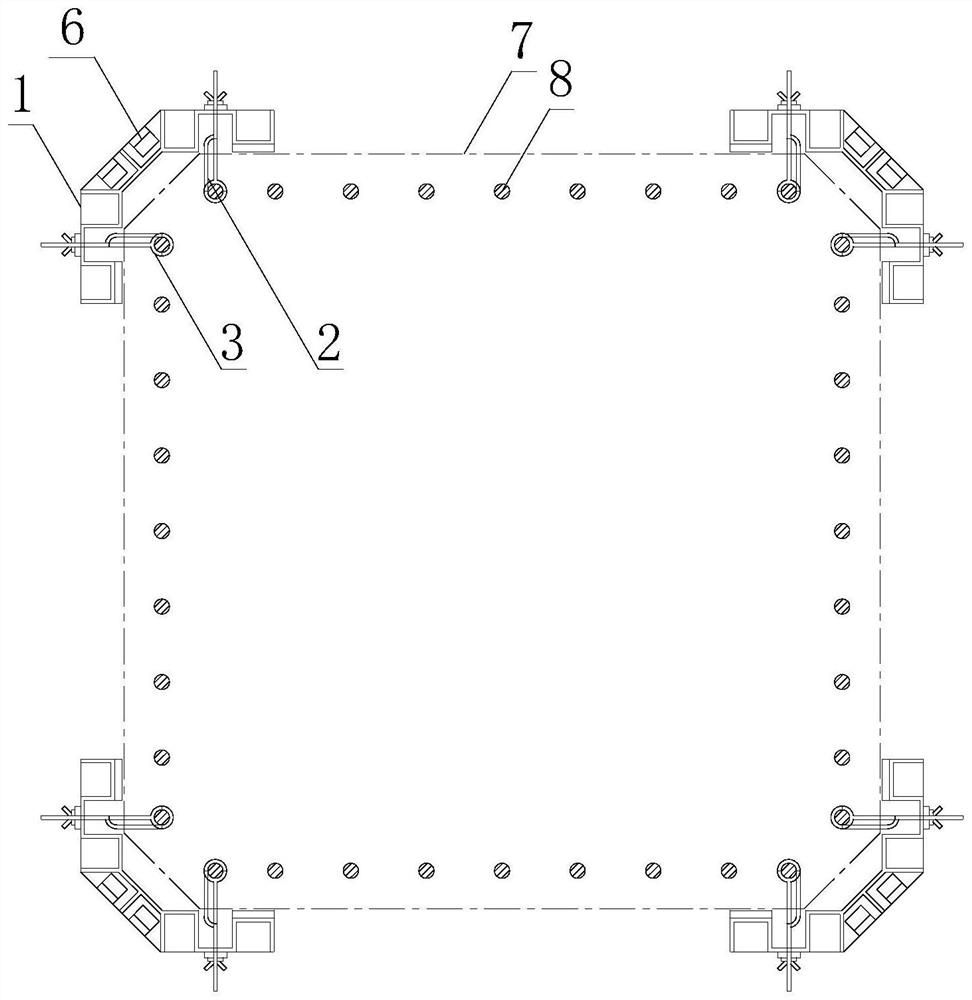

The invention relates to the technical field of infrastructure construction, in particular to a guide device for assembling and positioning a prefabricated polygonal bridge pier and a design method. The guide device comprises a plurality of position limiting plate assemblies, wherein the position limiting plate assemblies are connected with the bridge pier to form a guide surface; each position limiting plate is at least connected with two positioning pull buckle assemblies and two positioning top buckle assemblies; one end of each positioning pull buckle assembly and one end of the corresponding positioning top buckle assembly are connected with the corresponding position limiting plate through a screw bolt; and the other end of each positioning pull buckle assembly and the other end of the corresponding positioning top buckle assembly are connected with a corresponding embedded steel bar. The guide device and the design method have the advantages that assembly type components are used and combined to form a whole; field transportation and movement are convenient; the embedded steel bars of the structure per se are used for positioning and force bearing; the installation is convenient; the device is light and ingenious; guide hole passages formed by the position limiting plates in a vertical curved surface form have the big upper side and the small lower side, the bridge pierpositioning deviation in the construction process can be allowed, and the construction difficulty is reduced; and the plates are mutually combined, position limiting holes are transversely adjustable,and adaptability to different types of polygonal prefabricated bridge piers can be realized.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD +1

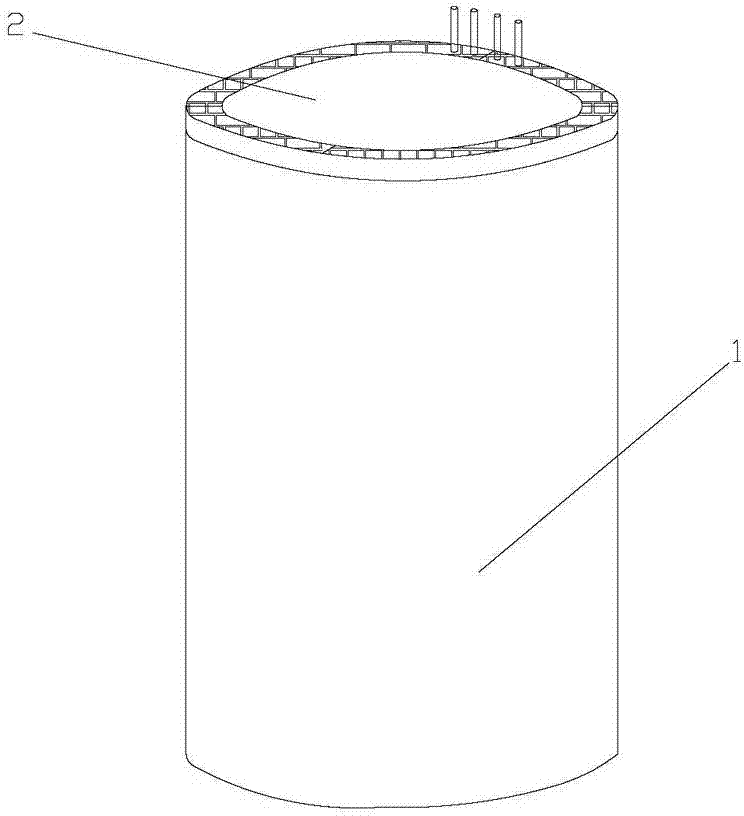

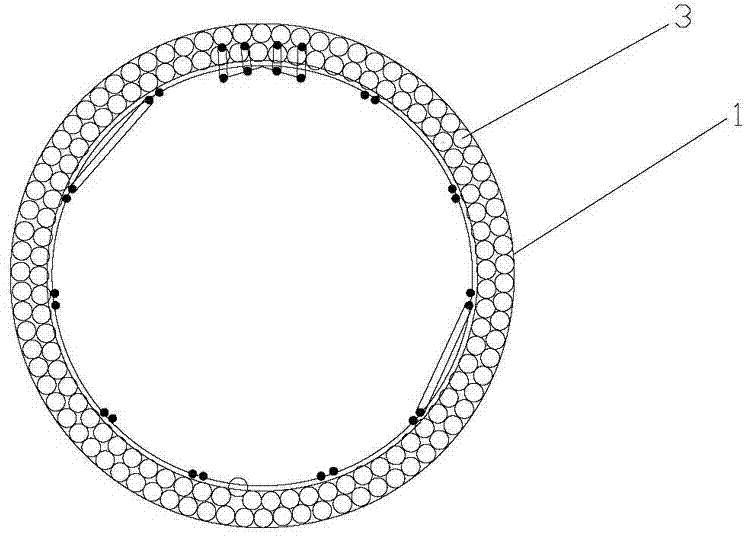

Buried heat storage tank

InactiveCN102853703ALow heat loss coefficientHigh compressive strengthHeat storage plantsEnergy storageThermal insulationPolyvinyl chloride

The invention discloses a buried heat storage tank which comprises a tank body. The tank body is composed of a tank body wall, a tank body thermal insulation top cover and a tank body thermal insulation bottom plate. A thermal insulation pipe is adhered to the inner wall of the tank body, the thermal insulation pipe is arranged on the inner wall of the tank body in surrounding mode, a heat exchanger is installed in the tank body, a radiator and a heating device are fixedly installed in the tank body, and the thermal insulation pipe is composed of a polyvinyl chloride (PVC) pipe and polyurethane materials filled in the PVC pipe. The buried heat storage tank is buried under the ground and used for storing solar energy, and is simple to install, low in cost, rapid in installation speed, capable of storing the solar energy for a long time, good in thermal insulation effect and particularly suitable for a single family.

Owner:STARS GUANGZHOU REFRIGERATING EQUIP MFG

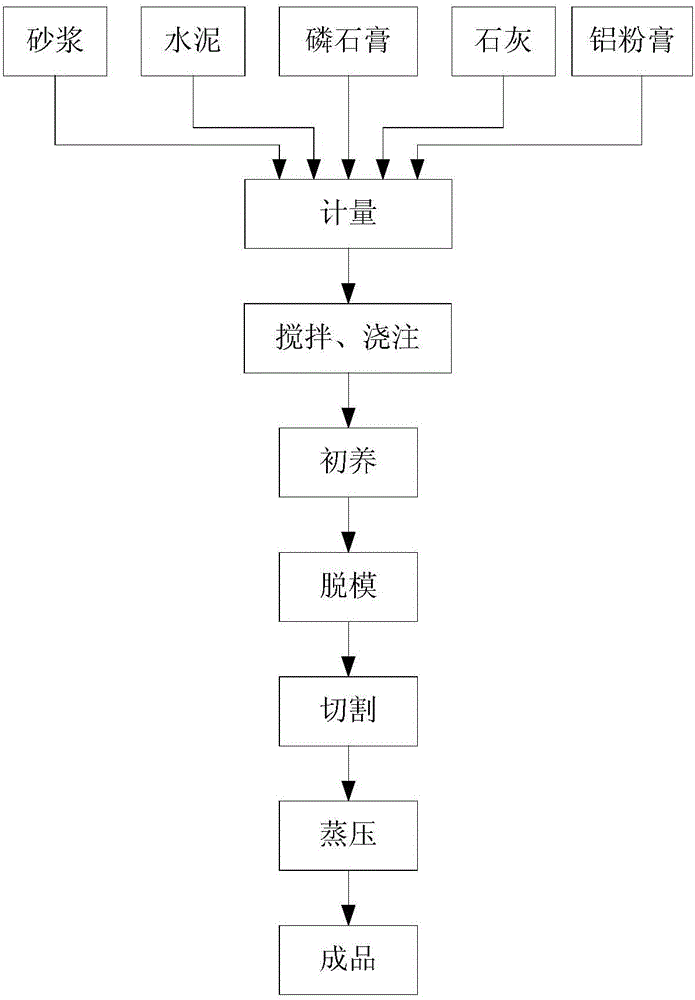

Method for producing autoclaved aerated concrete building blocks

The invention discloses a method for producing autoclaved aerated concrete building blocks, which relates to the technical field of concrete building blocks. The method comprises the following steps: performing burdening, metering, stirring, casting, primary maintenance, cutting, and autoclaving on the mortar, lime, cement and phosphogypsum to prepare the autoclaved aerated concrete building blocks. The produced autoclaved aerated concrete building blocks have good processing performance, steel bar can be added during a production process, large convenience and flexibility can be provided to construction, masonry manual work is saved, on-site construction progress is accelerated, construction efficiency is increased, the preparation method has the advantages of easy and convenient operation, and environment pollution can be effectively avoided.

Owner:ANHUI JIANSHENG JIYUAN NEW MATERIAL TECH CO LTD

A two-way prefabricated segment assembly method for large-scale underpass

ActiveCN105002931BReduce distractionsGuaranteed stabilityArtificial islandsUnderwater structuresPre stressArchitectural engineering

The invention discloses a two-way prefabricated section assembly method for a large-size underpass, which belongs to the technical field of traffic engineering. The closed frame structure of the underpass is spliced by a prefabricated assembly construction method, and shear keys are arranged on the longitudinal and upper and lower splicing surfaces. The splicing seams are glued with structural glue, the upper and lower splices use their own weight to form pressure, and the upper and lower joints are equipped with connecting steel plates. After the glue is completed, they are welded with the pre-embedded steel plates in the upper and lower segments. Temporary prestress is set for longitudinal splicing to form a large segment Post-tensioning permanent prestressing ensures the long-term integrity of large sections. The prefabricated sections adopt factory prefabrication and are carried out synchronously with the excavation of the foundation pit, so that urban roads with a certain scale and traffic interference during the construction period have a greater impact on production and life. It has been carried out smoothly, greatly shortening the construction period, speeding up the on-site construction progress, greatly reducing the construction procedures such as on-site formwork, steel bar cutting, binding and welding, and concrete pouring, and reducing dust and noise pollution to surrounding areas.

Owner:XIAMEN MUNICIPAL ENGINEERING DESIGN INSTITUTE CO LTD

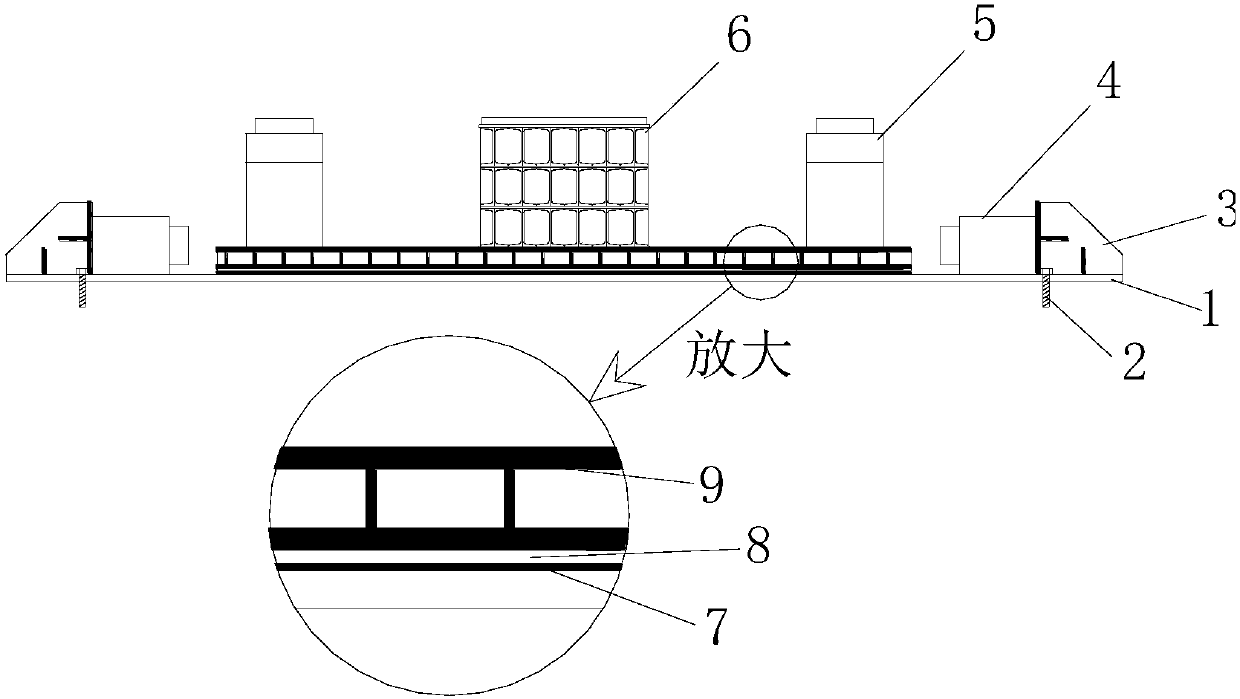

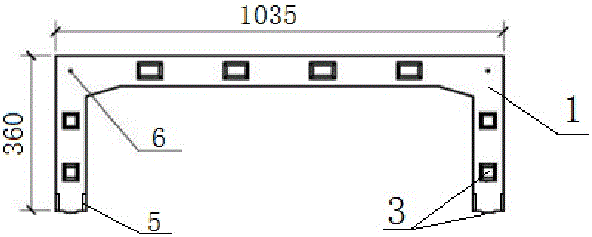

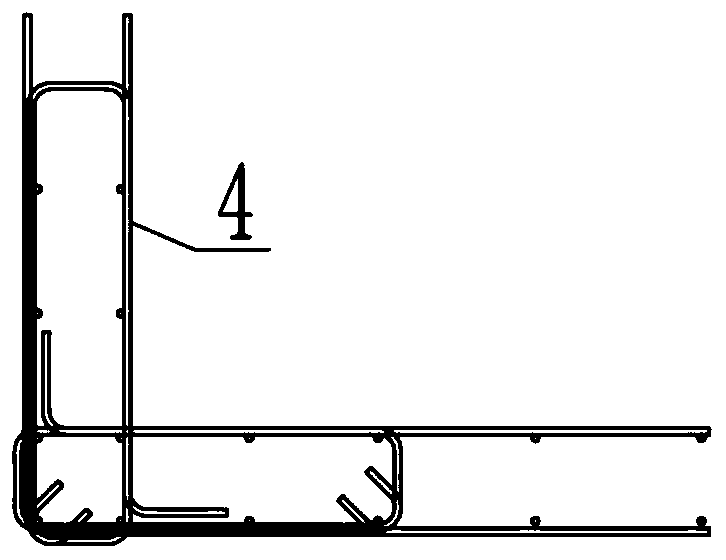

Rebar formwork integrated L-shaped wall component and production method thereof

PendingCN110042957ASpeed up on-site construction progressSimple structureWallsCeramic shaping apparatusRebarShear wall

The invention discloses a rebar formwork integrated L-shaped wall component and a production method thereof. The rebar formwork integrated L-shaped wall component includes an external corner L-shapedformwork, an internal corner L-shaped formwork, an external corner formwork reinforcing piece, an L-shaped wall rebar framework and an oppositely pulling connecting piece, and the external corner L-shaped formwork is located at the external corner of the rebar formwork integrated L-shaped wall component and composed of first external corner L-shaped formwork sub-limbs and second external corner L-shaped formwork sub-limbs which are mutually perpendicular; the internal corner L-shaped formwork is located at the internal corner of the rebar formwork integrated L-shaped wall component and composed of first internal corner L-shaped formwork sub-limbs and second internal corner L-shaped formwork sub-limbs which are mutually perpendicular; and the middle of the oppositely pulling connecting piece is fixed on the L-shaped wall rebar framework, and the external corner L-shaped formwork, the internal corner L-shaped formwork and the L-shaped wall rebar framework form the integrated component. According to the rebar formwork integrated L-shaped wall component and the production method thereof, rebars and the formworks of an L-shaped wall in a shear wall structure are integrated, the formworks are free of removal, the site construction progress is accelerated, and the integrated component is low in weight, convenient to install, simple in construction and convenient to product and process.

Owner:CHINA RAILWAY CONSTR GROUP +1

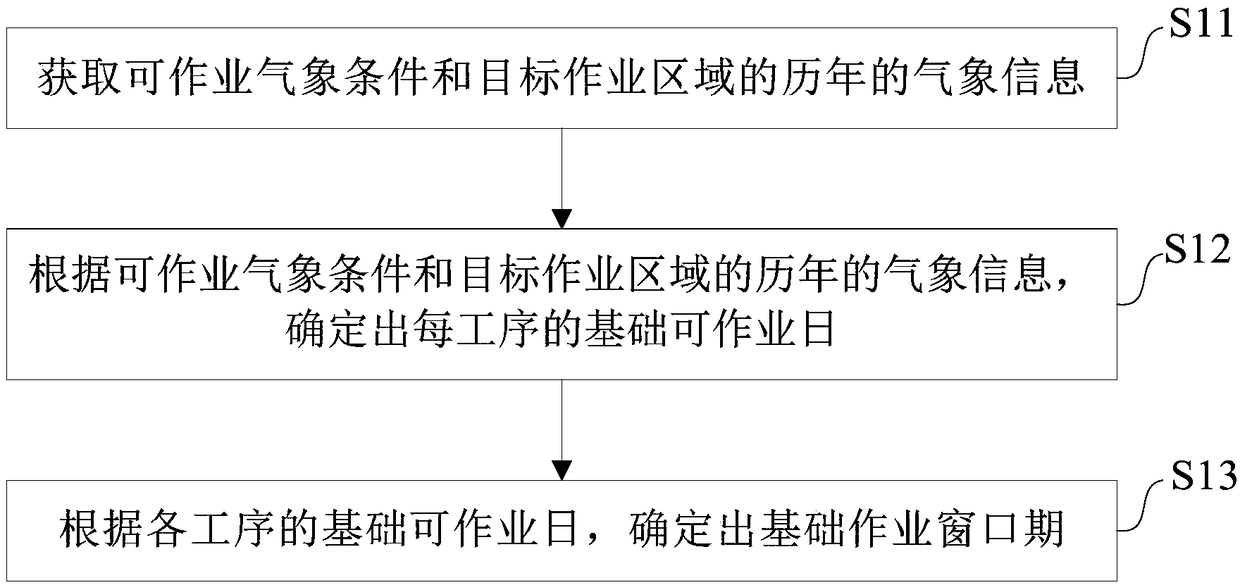

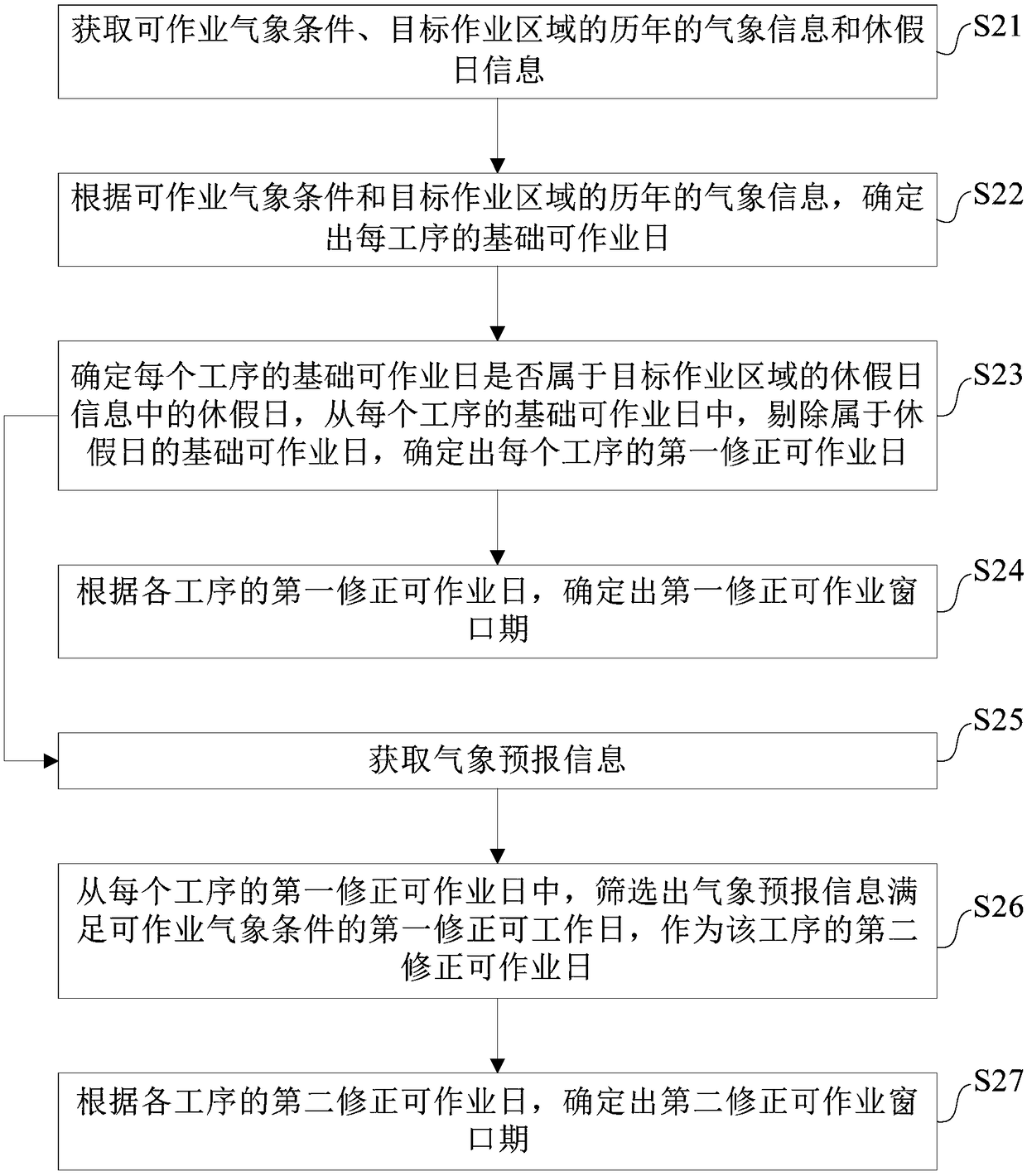

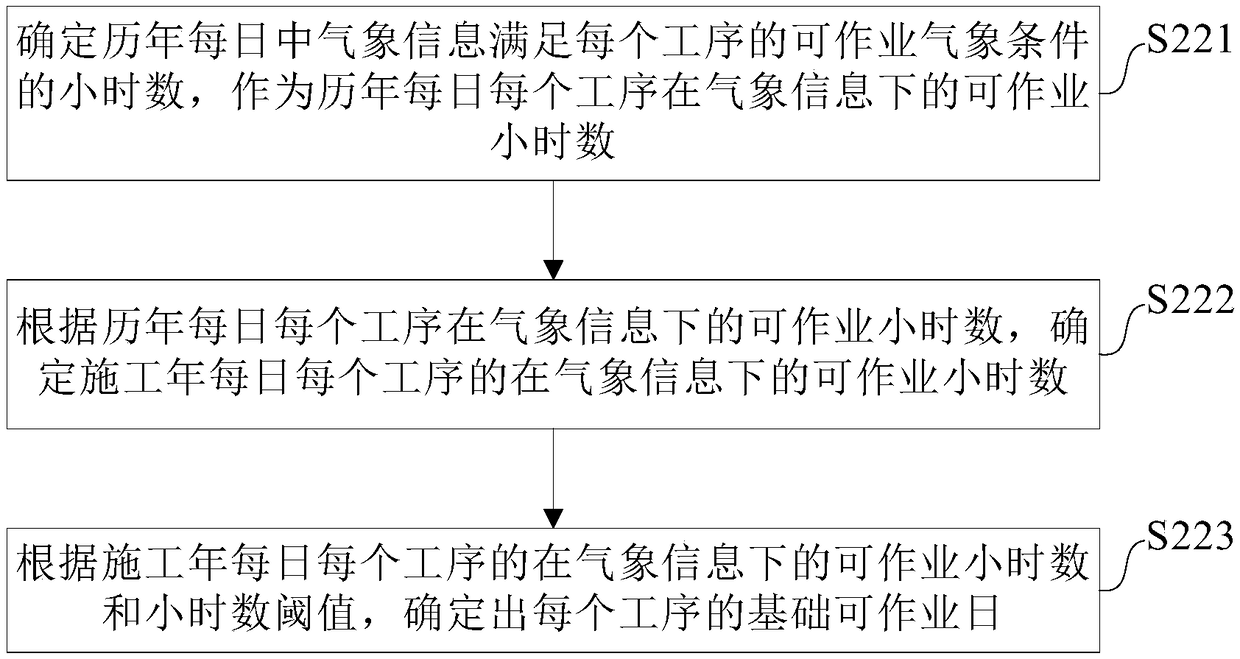

Method and device for predicting operation window period and electronic device

InactiveCN109447339AReasonable arrangementShorten the construction periodForecastingResourcesPredictive methodsProject cycle

Embodiments of the present application provide a method and device for predicting an operation window period and an electronic device. The method includes obtaining the weather information of a workable weather condition and a target work area in a calendar year; according to the operational meteorological conditions and the meteorological information of previous years, determining the basic operational days of each working procedure; according to the basic workable days of each operation, determining the window period of basic work. Since the meteorological information of a calendar year canprovide the complete meteorological data of a certain year or years in the past, it is therefore possible to determine dates that meet the operational meteorological conditions over a longer period ofthe calendar year, so as to determine the basic workable days of each working procedure in the longer period of the construction year according to the dates in the longer period of the calendar yearwhich are in conformity with the workable meteorological conditions. Then the operation window period which can cover the whole project cycle can be obtained. By using the operation window period, theconstruction plan can be arranged reasonably, the construction period can be shortened significantly, the construction cost can be controlled effectively, and the construction progress can be accelerated.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

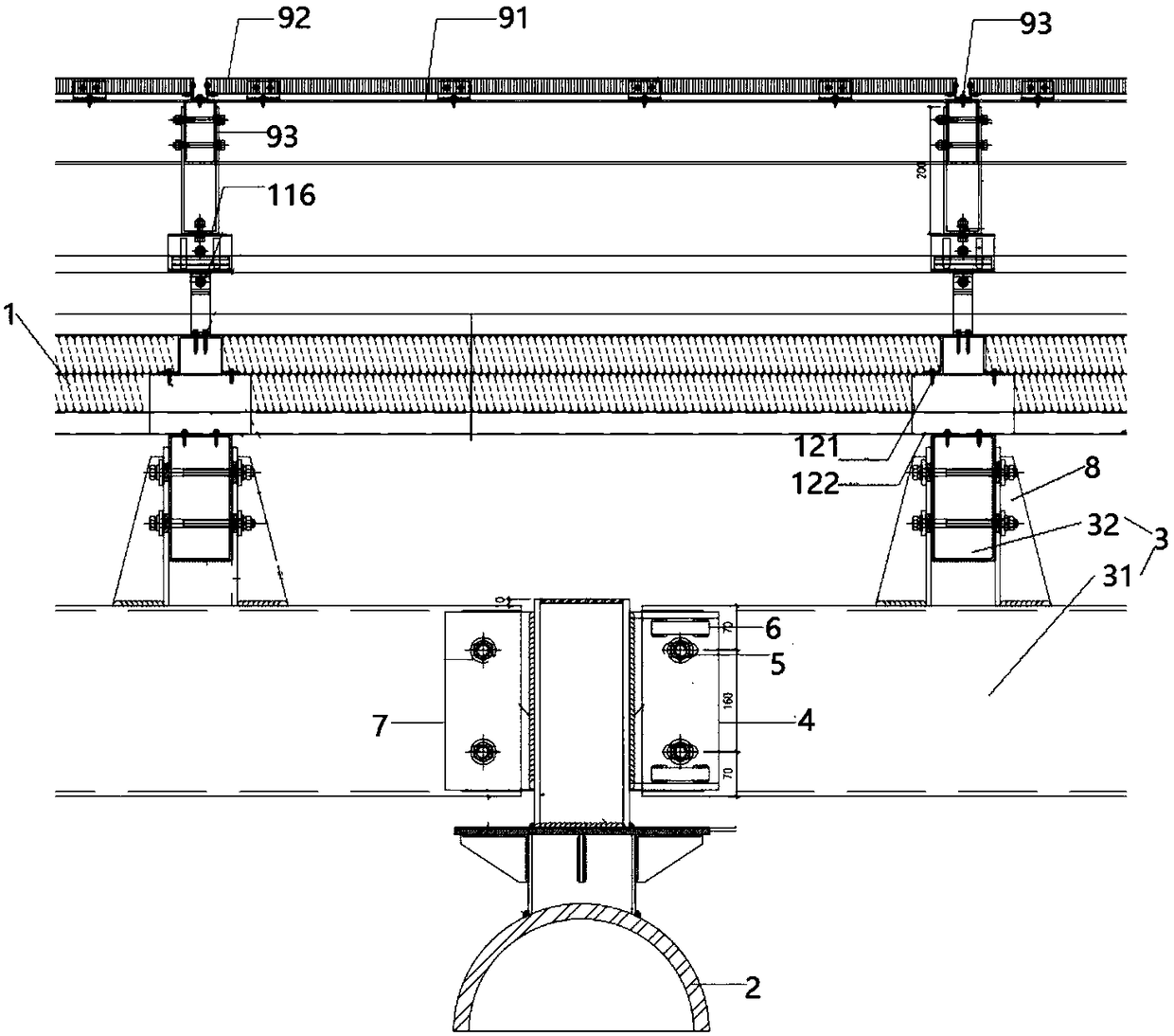

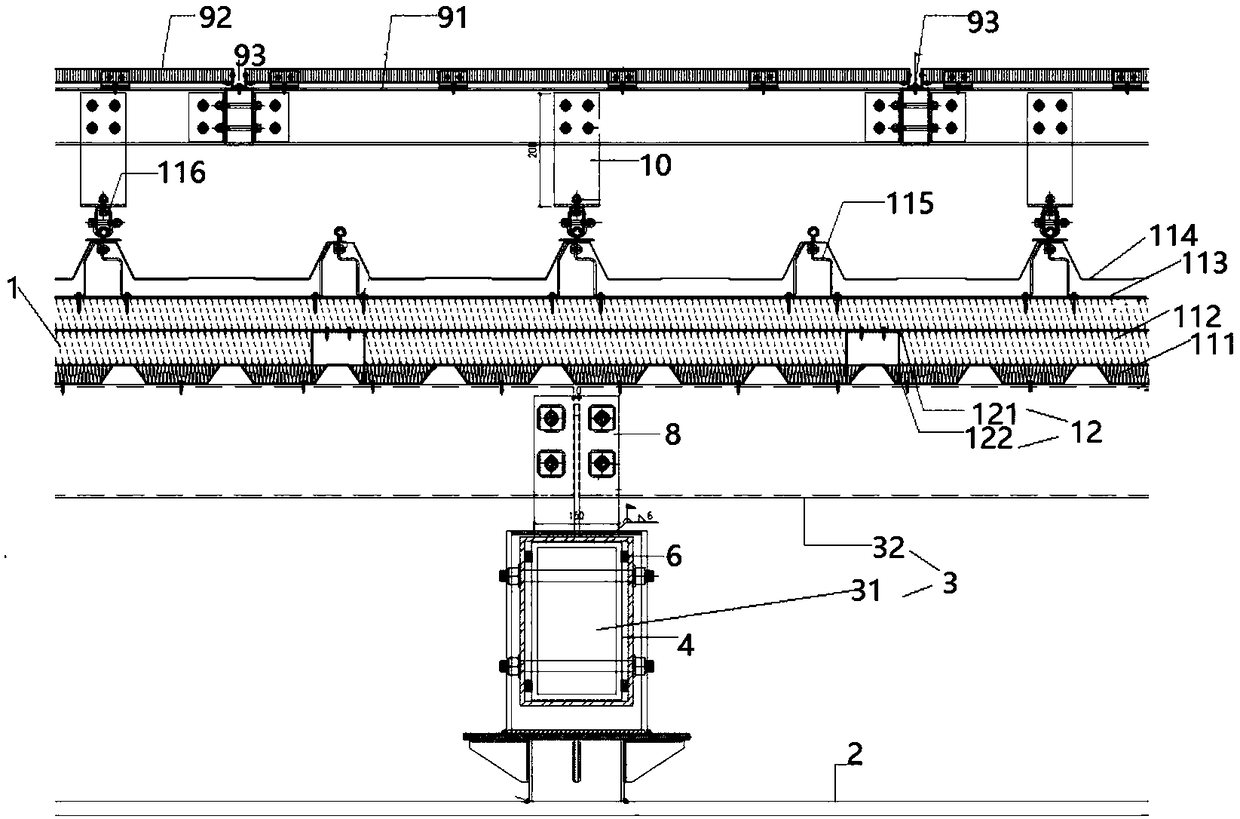

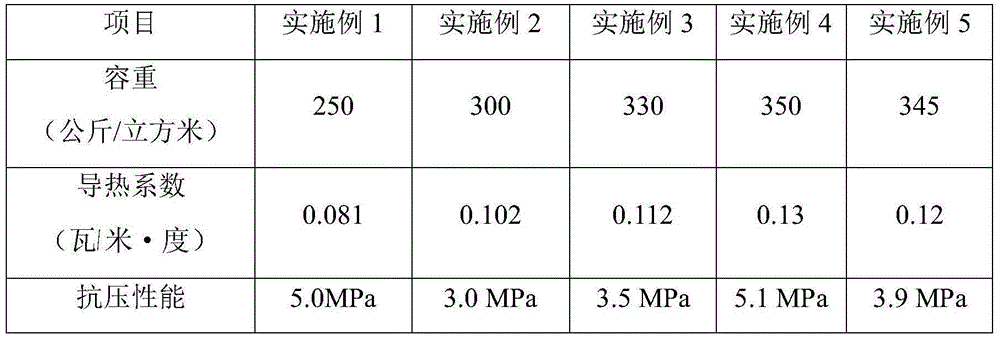

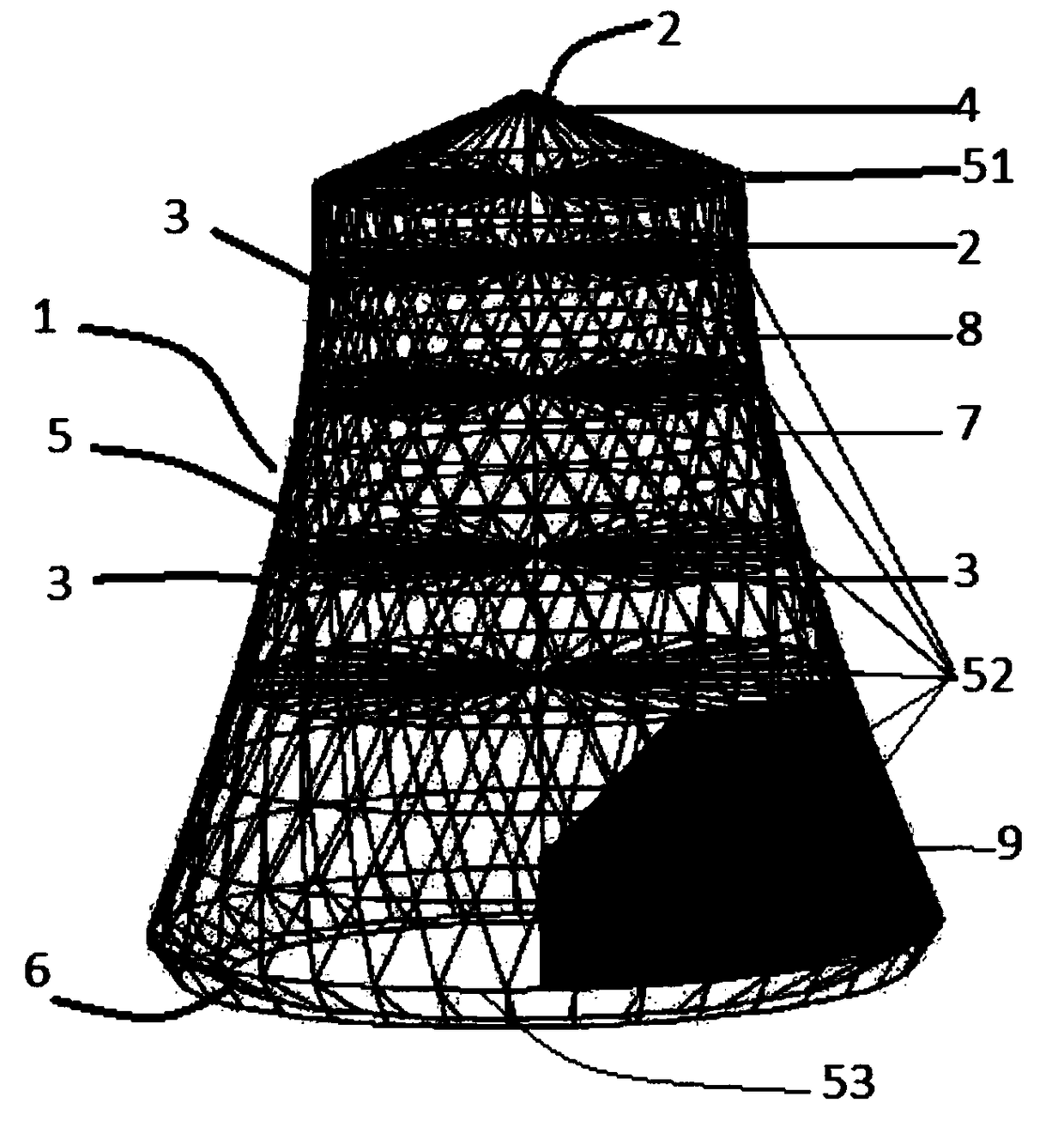

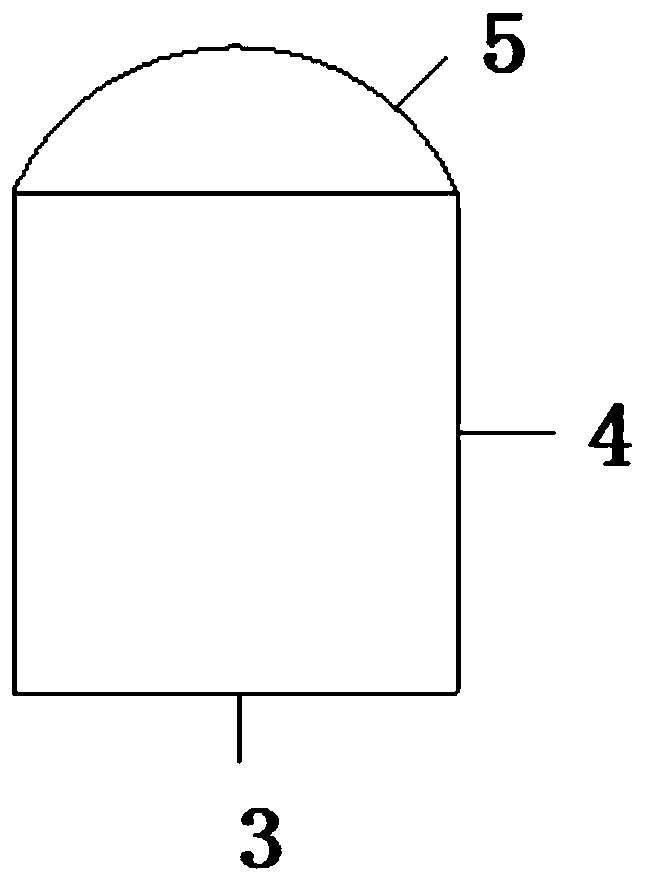

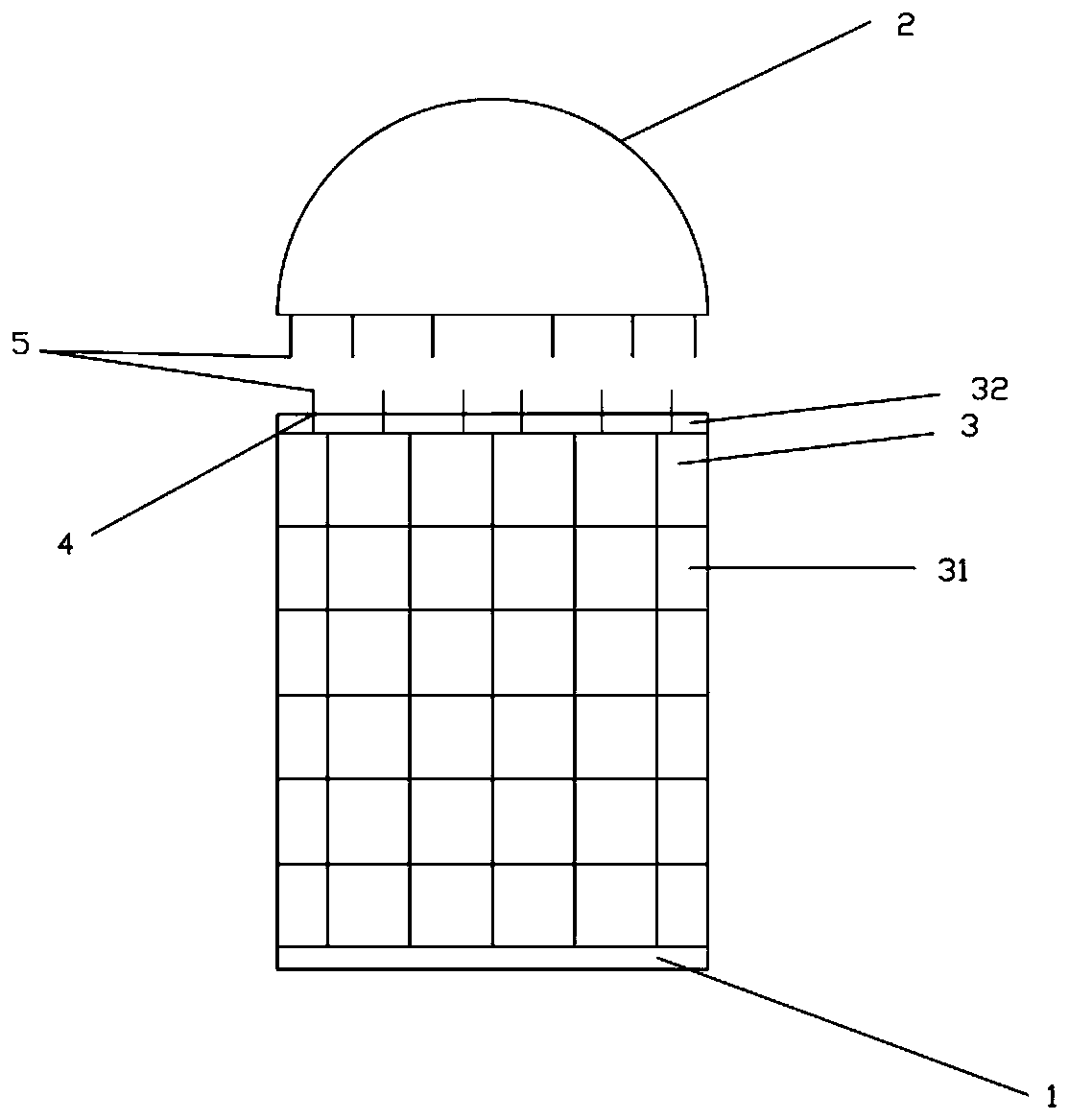

Cooling tower and construction method thereof

InactiveCN108412257AReduce the weight of the structureSpeed up on-site construction progressCooling plantsCooling towerEngineering

An embodiment of the invention discloses a cooling tower and a construction method thereof, and relates to the technical field of building structures. The construction progress of the cooling tower can be improved, and structural dead weight is relieved. The cooling tower comprises a tower barrel and a tower column, the tower barrel comprises a barrel structure framework mainly formed by connecting metal ropes, the tower column is a rigid column and arranged in the barrel structure framework, a supporting beam is radially connected onto the tower column, and the end of the supporting beam is connected onto the barrel structure framework. The cooling tower and the construction method thereof are applicable to research, design and application of cooling tower structures such as laboratoriesand power plants.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

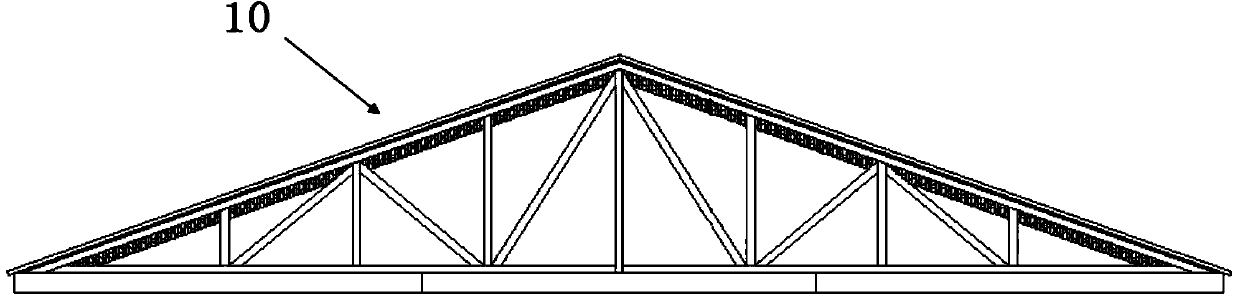

Partition board and small-sized single-layer synthetic-wood house construction method based on same

InactiveCN103741870AReduce engineering costsReduce the difficulty of on-site construction workWallsProtection layerMono layer

The invention relates to a partition board and a small-sized single-layer synthetic-wood house construction method based on the partition board. The partition board comprises a partition board main body, wherein the partition board main body consists of material layers and is in a hollow structure, and a heat-preserving heat-insulation protection layer is arranged in the hollow structure; the outer surface of the partition board main body is wrapped by a decorative plate. The construction method comprises the following steps of (1) producing the partition boards, stand columns, beams, door pockets and window pockets; (2) arranging an iron plate embedded member; (3) fixedly connecting the stand columns with the iron plate embedded member; (4) inserting the partition boards into grooves of the stand columns; (5) fixing the beam onto the top end of each stand column to form a ring beam; and (6) fixing a light steel structural roof skeleton onto the ring beam so as to complete the assembling of the house. The partition board is low in cost, simple in construction operation and capable of being used as a veneer for decoration. By adopting the house construction method, the problems of the traditional construction method that the cost is high, the speed is low, the appearance is not attractive and no fireproof function is available can be solved. The partition board and the method can be widely applied to the building field.

Owner:韩杰

Sequence construction method for super-long concrete structure

InactiveCN112282166ACrack controlGuaranteed continuityFloorsBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a sequence construction method for a super-long concrete structure. Concrete cracks can be effectively controlled through sequence construction and the optimized concrete mix proportion, the problem that potential quality hazards exist when a post-cast strip is used in the super-long concrete structure is solved, the continuity of construction procedures is guaranteed, subsequent procedures can be alternately performed in advance, the on-site construction progress is accelerated, the certain construction cost is saved, and the construction period is greatly shortened. The method solves the problem that the construction period is long due to the fact that the post-cast strip is reserved for construction through a traditional construction method in the super-long and super-wide concrete structure.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

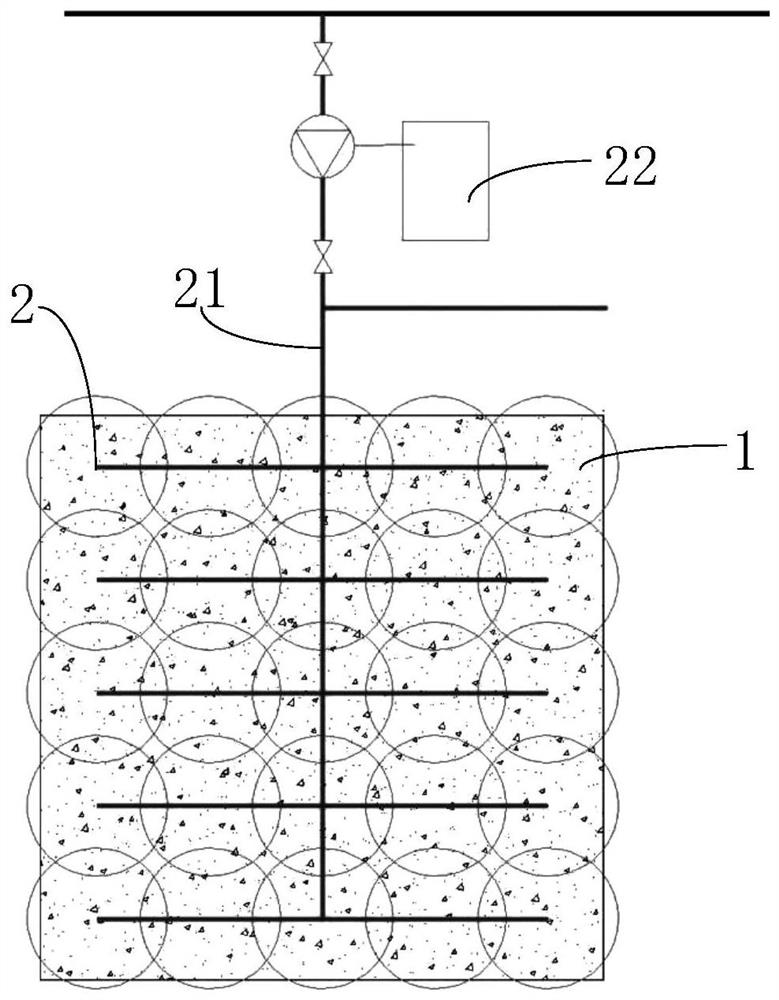

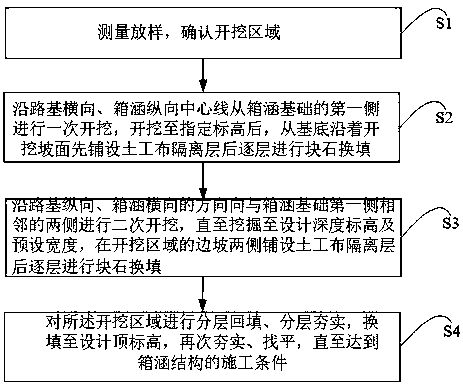

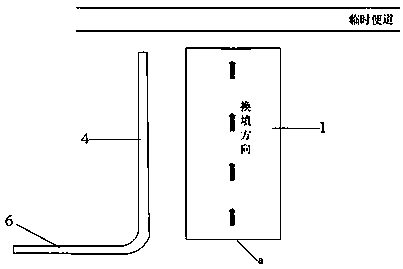

Method for foundation replacement construction of peat soil soft foundation box culvert

InactiveCN111472359ASpeed up on-site construction progressImprove post-work stabilityGround-workSewerage structuresGeotextilePeat

The invention provides a method for foundation replacement construction of a peat soil soft foundation box culvert. The method comprises the following steps of, measuring and setting out, and confirming an excavation area; carrying out excavation for the first time from the first side of the box culvert foundation along the transverse direction of the roadbed and the longitudinal centerline of thebox culvert, and laying geotextile isolation layers along the excavation slope surface from the foundation base after the excavation reaches the specified elevation, and then carrying out stone replacement in layers; carrying out excavation for the second time on two sides adjacent to the first side of the box culvert foundation along the longitudinal direction of the roadbed and the transverse direction of the box culvert until the excavation reaches the design depth elevation and the preset width, and laying geotextile isolation layers on the two sides of the slope of the excavation area, and then carrying out stone replacement in layers; and carrying out backfilling in layers and tamping in layers of the excavation area, carrying out replacement until reaching the designed top elevation, and carrying out tamping and leveling until reaching the construction conditions of a box culvert structure. According to the method, the field construction progress of the peat soil soft foundation can be accelerated, the geotextile isolation layers are added, and the peat soil layer is isolated from stone replacement part, thus avoiding the mixed impact upon stability of the box culvert foundation.

Owner:CHINA MCC20 GRP CORP

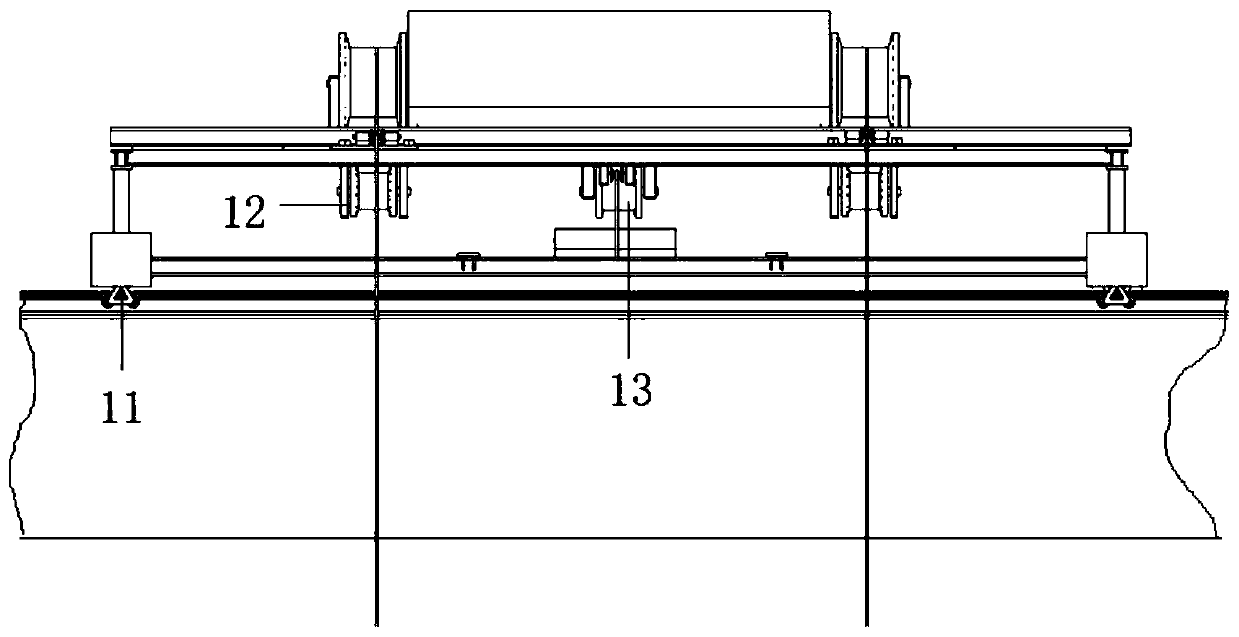

Attached hoisting and transporting device for dismantling concrete supporting beams and using method of attached hoisting and transporting device

ActiveCN111392589ASolve the problem of difficult liftingAlleviate the problem of difficulty in dismantling and liftingBuilding repairsTravelling cranesChinese charactersBlock and tackle

The invention discloses an attached hoisting and transporting device for dismantling concrete supporting beams and a using method of the attached hoisting and transporting device. The hoisting and transporting device comprises a trolley system and a hosting system, the trolley system comprises a trolley arranged on operation tracks, the trolley comprises an upper-layer frame structure shaped likethe Chinese character 'mu' and a lower-layer frame structure shaped like the Chinese character 'mu', a balance weight tray is arranged on a lower steel plate and connected with a balance weight adjusting rope which is connected with a balance weight adjusting winch, and a self-powered speed limiting braking device is mounted on a pulley block; and rack winches having the same power and operating synchronously are fixed to the middles of operation tracks at the two side edges of a foundation pit correspondingly, and the balance weight adjusting winch, a cantilever beam, the rack winches and twolifting winches constitute the hoisting system, wherein the two lifting winches have the same power and operate synchronously. The problems of multi-layer form dismantling and hoisting of the supporting beams in the vertical direction are effectively solved, the attached hoisting and transporting device can be used for dismantling, hoisting and transporting of the oversized and large-section concrete supporting beams, the pressure of hoisting operation is relieved, and the construction progress is guaranteed.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

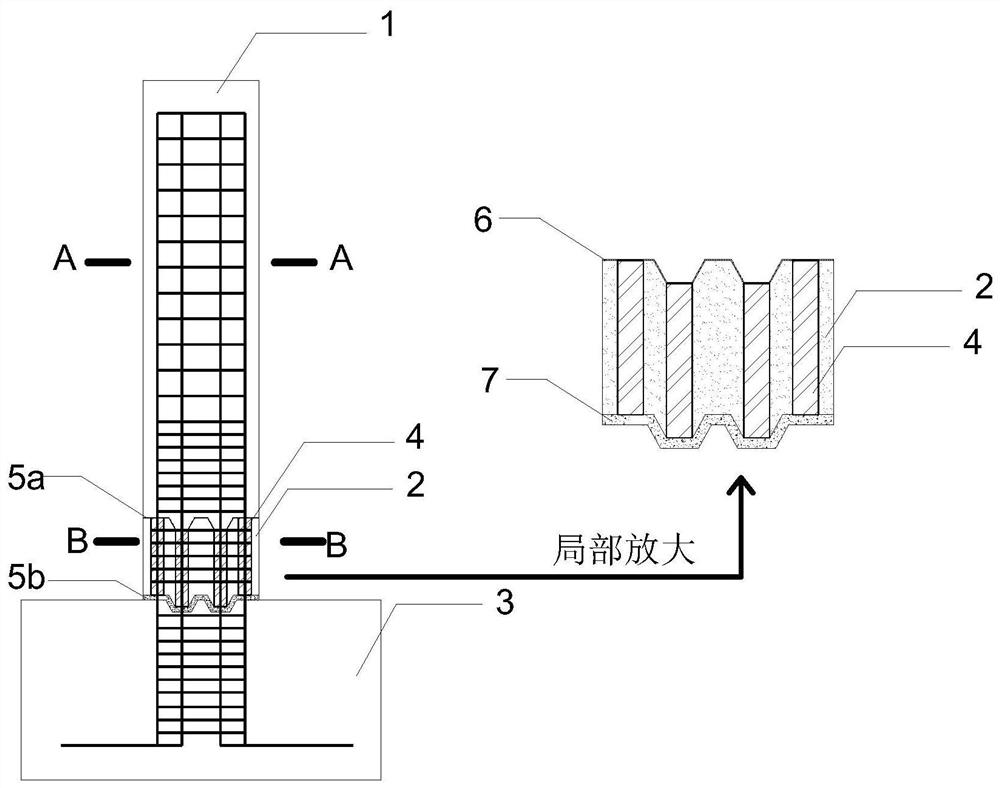

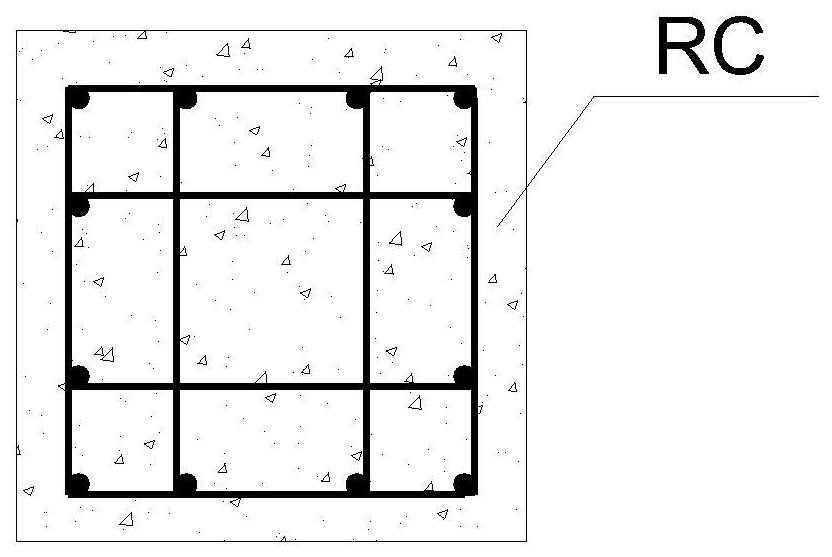

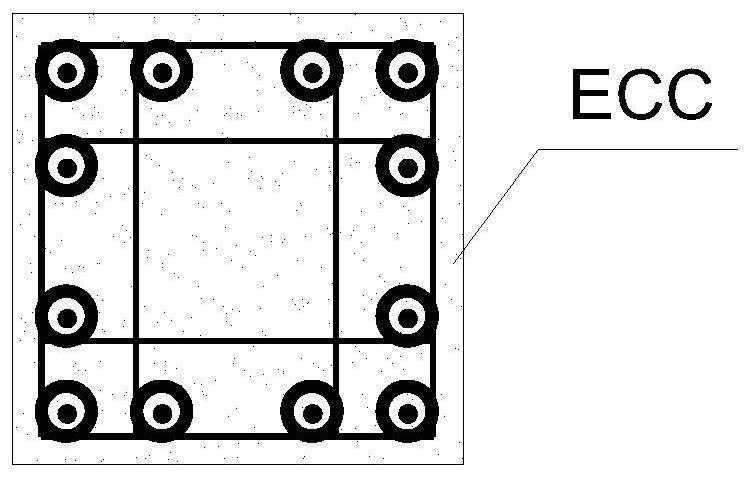

An assembled ecc-rc mixing column connected by grouting sleeve

ActiveCN112982829BImprove crack resistanceImprove energy consumptionStrutsClimate change adaptationEarthquake resistanceEconomic benefits

Owner:BEIJING UNIV OF TECH

Shear wall horizontal rib installation positioning rod and construction method

PendingCN111636692AEasy to makeCost controlBuilding material handlingArchitectural engineeringShear wall

The invention provides a shear wall horizontal rib installation positioning rod and a construction method. The shear wall horizontal rib installation positioning rod comprises a main rod, wherein a plurality of positioning cross rods are welded and fixed to the side wall of the main rod at equal intervals in the height direction of the main rod, and a limiting vertical rod is vertically welded andfixed to the top of the tail end of each positioning cross rod; and the positioning cross rods are sleeved with rotating sleeves. The positioning rod can be used for auxiliary installation of a shearwall horizontal rib, the position precision and levelness of horizontal rib installation are guaranteed, meanwhile, the installation difficulty is effectively reduced, the installation of the horizontal rib can be completed by a single person, and the labor cost of operation is reduced.

Owner:CHINA NUCLEAR IND 22ND CONSTR

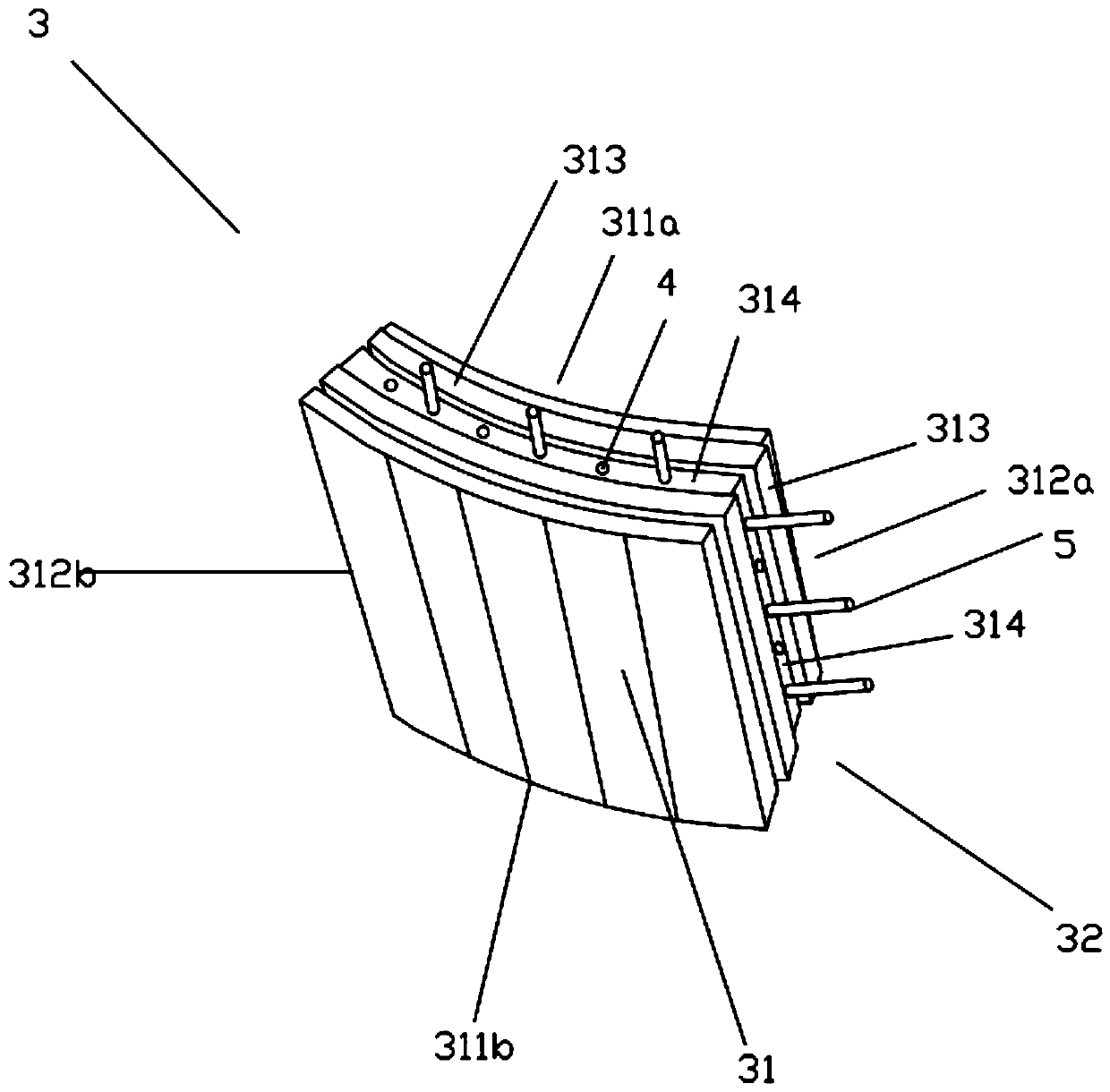

A modular prestressed concrete shell and modular shell assembly method

ActiveCN107035025BEasy to removeSpeed up on-site construction progressWallsArched structuresModularityEngineering

The invention discloses a modular prestressed concrete shell body comprising a base plate and a dome which are poured in site and further comprising a plurality of cylinder body shell body modules. A connecting part on the peripheral surface of a main body part of each cylinder body shell body module and a connecting part of a main body part of the corresponding adjacent cylinder body shell body module are inserted mutually and connected through prestressed bars of prestressed bar hole channels in the main body parts of the cylinder body shell body modules to enable the multiple cylinder body shell body modules to be combined to form a cylinder body. One side of the cylinder body is connected with the base plate in a pouring mode, and the other side of the cylinder body is connected with the dome through the prestressed bars inserted into the prestressed bar hole channels in the cylinder body and the dome in a penetrating mode. The invention further discloses a modular prestressed concrete shell body assembling method. Through the modular prestressed concrete shell body, the problem that an existing shell body is high in site construction difficulty, long in construction period and large in dismantling difficulty at the time of decommissioning.

Owner:中广核工程有限公司 +1

A kind of construction method of imitation wood villa house with steel structure skeleton

InactiveCN103696585BReduce engineering costsLow costBuilding componentsDwelling buildingWood veneerKeel

Owner:韩杰

Breakdown fault location method of gis field pressure test based on vibration test

ActiveCN103777124BImprove test accuracyAvoid the trouble of large-scale disassembly inspectionTesting dielectric strengthTime differenceBreakdown voltage

The invention relates to a breakdown failure positioning method of a GIS on-site voltage withstand test based on a vibration test. A plurality of vibration sensors are distributed on a GIS outer shell within a test range to carry out monitoring, the vibration signals generated when a GIS breakdown failure occurs are collected, and failure positioning is carried out by comparing the amplitude difference and time difference between monitoring point signals. Compared with the prior art, the breakdown failure positioning method of the GIS on-site voltage withstand test based on the vibration test has the advantages of being high in test accuracy and saving the trouble of large-area detachment examination by achieving failure positioning through the vibration test, thereby effectively improving the on-site construction progress, and meanwhile eliminating quality hidden risks caused by large-area detachment.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com