Attached hoisting and transporting device for dismantling concrete supporting beams and using method of attached hoisting and transporting device

A transportation device, concrete technology, applied in the direction of transportation and packaging, walking bridge cranes, cranes, etc., to achieve the effect of ensuring construction safety, simple structure, and improving site construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

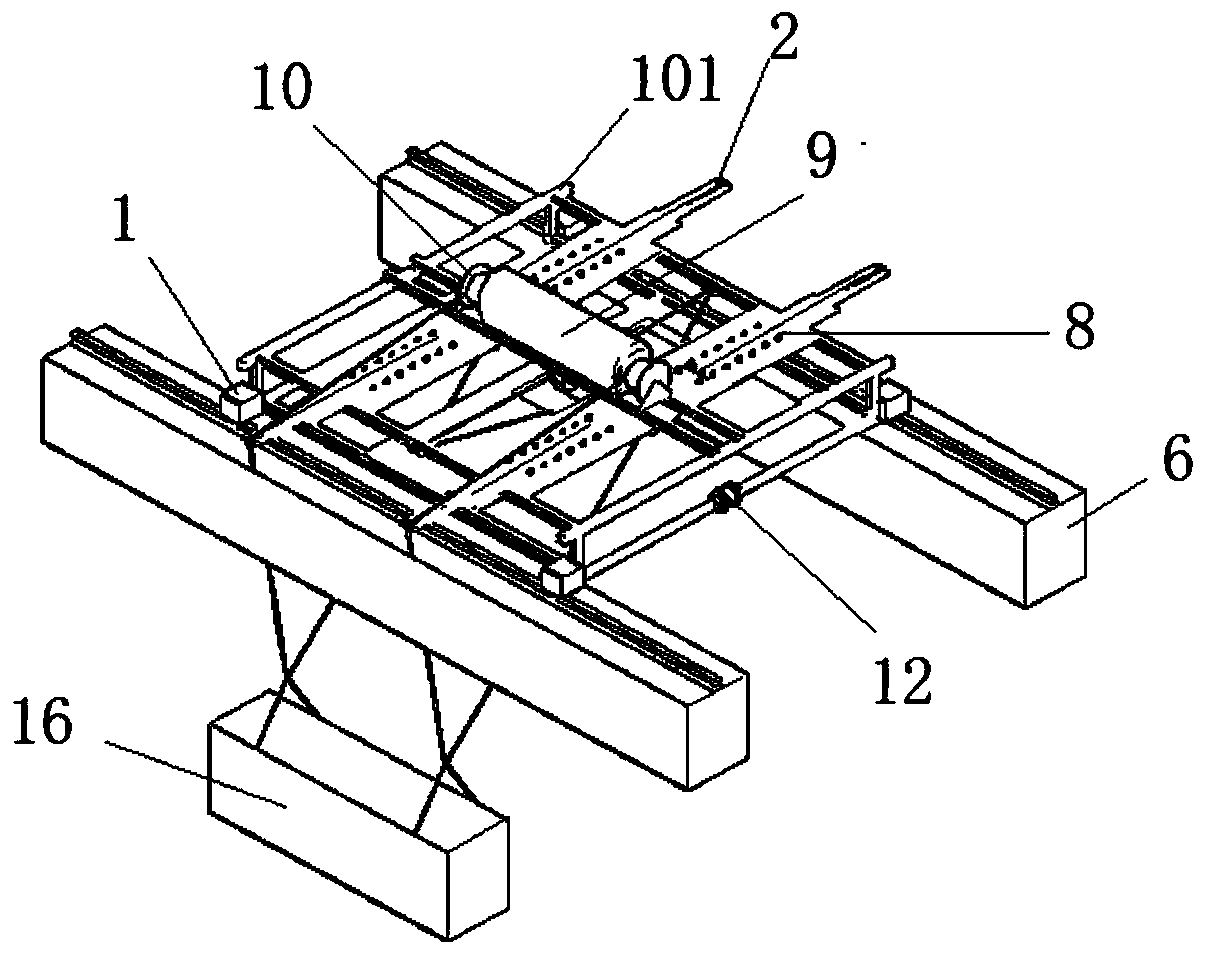

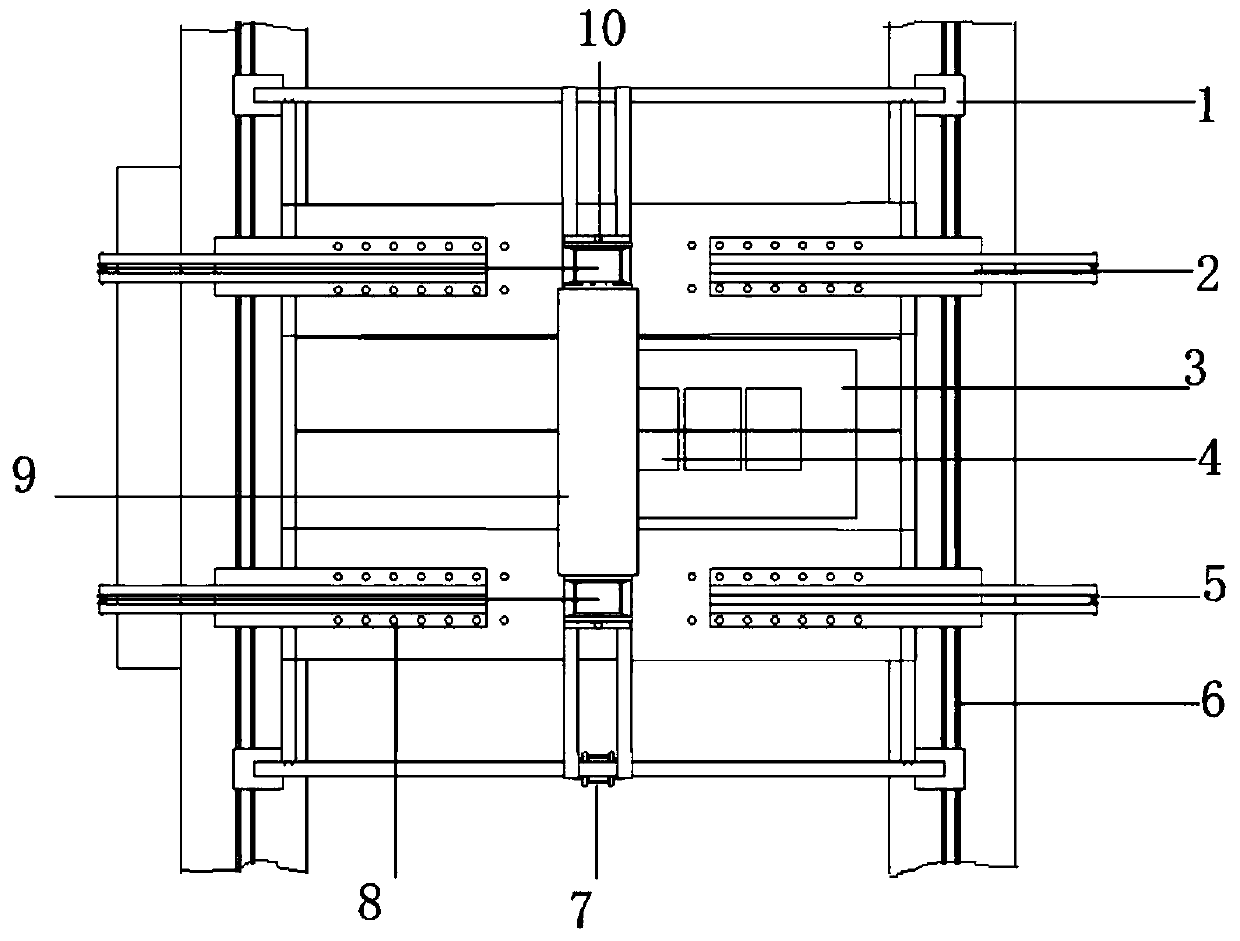

[0037] An attached lifting and transporting device for demolishing concrete support beams, including a trolley system and a lifting system, see figure 1 , the trolley system includes a trolley 101 arranged on the running track 6, and the trolley 101 is set as a structure including upper and lower layers of "mesh"-shaped frames, and the "mesh"-shaped frames are all composed of beam connections, and the upper 1. The "mesh"-shaped frames on the lower two floors are all connected by vertical connecting beams at the four corners; see figure 2 , the middle part of the "mesh"-shaped frame of the upper layer is connected with the upper steel plate on the two vertical connecting beams perpendicular to the direction of the running track 6, and the two ends of the upper steel plate are respectively symmetrically provided with two rows of first bolt holes, each The number of the first bolt holes in each row is at least two, and they are evenly distributed. The four cantilever beams 2 are...

Embodiment 2

[0043] An attached lifting and transportation device for removing concrete support beams. On the basis of Embodiment 1, further, the two sides of the trolley system are respectively provided with support removal devices 17, and the support removal devices 17 are provided with concrete support beams. Block 16, the two ends of the concrete support beam block 16 are provided with reserved hoisting holes.

[0044] Furthermore, the ends of the hoisting rope 15 and the external force pulling rope 7 are respectively provided with matching locks.

[0045] Furthermore, the cantilever beam 2 is formed by welding one beam steel plate and two beam steel bars.

[0046] Furthermore, two rows of second bolt holes are provided on the beam steel plate, and the number of the second bolt holes in each row is at least two, and the number of the second bolt holes is evenly distributed.

[0047] Furthermore, the four cantilever beams 2 are evenly distributed into two groups, and are symmetrically ...

Embodiment 3

[0050] Embodiment 1 or embodiment 2 described attached demolition concrete support beams use the method of lifting, transportation device, comprise the following steps,

[0051] The first step is to lay and fix the running track 6 according to the needs of the scope of work;

[0052] In the second step, the trolley 101 is installed on the running track 6, and the suspension distance of the cantilever beam 2 is adjusted by adjusting the bolts of the cantilever beam 2 according to the maximum load of lifting;

[0053] The third step is to select the counterweight 4 according to the maximum lifting load, and place the counterweight 4 on the counterweight pallet 3;

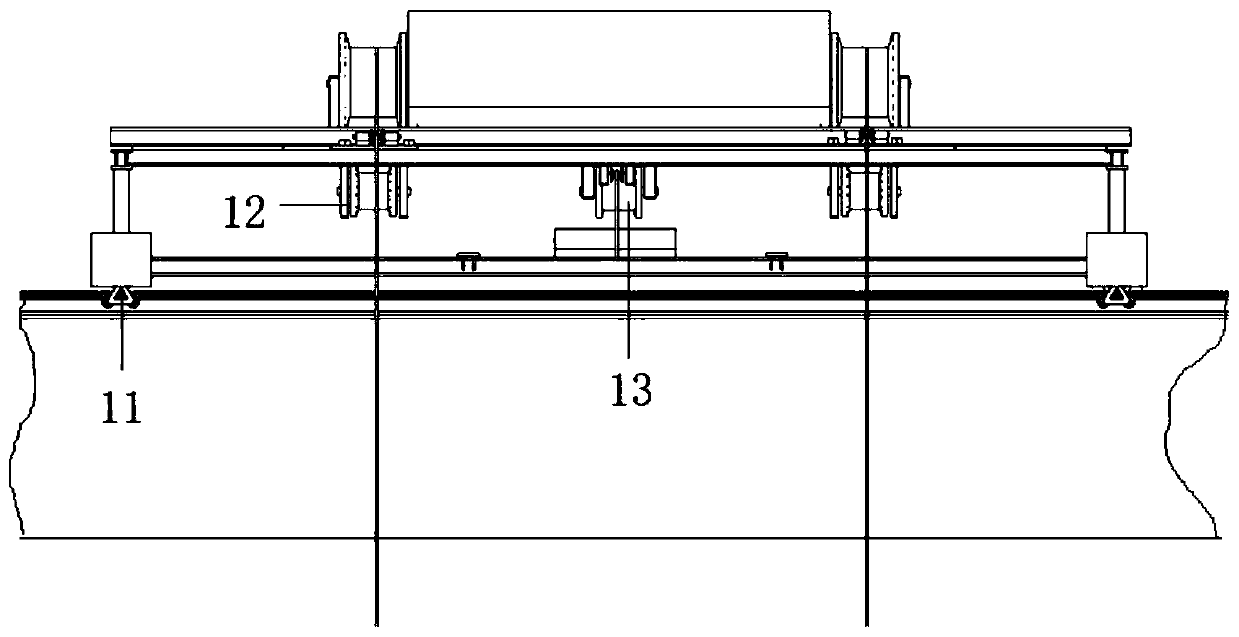

[0054] In the fourth step, the hoisting rope 15 and the external force traction rope 7 are drawn out from the hoisting hoist 10 and the traction hoist 12 respectively, and are extended downward through the guide wheel 5 on the hoisting side;

[0055] In the fifth step, the trolley 101 moves to the top of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com