Vertical lifting and horizontal alignment lifting method of main chord member

A hoisting method and main chord technology, which is applied in the directions of transportation and packaging, load hanging components, erection/assembly of bridges, etc. It can solve the problems of heavy weight of steel truss arch members, narrow space of closing section, and inability to meet construction requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] see Figure 1 to Figure 4 , a hoisting method for vertical hoisting and horizontal alignment of a main chord, which mainly involves vertical hoisting first and then horizontal alignment. The specific steps are as follows:

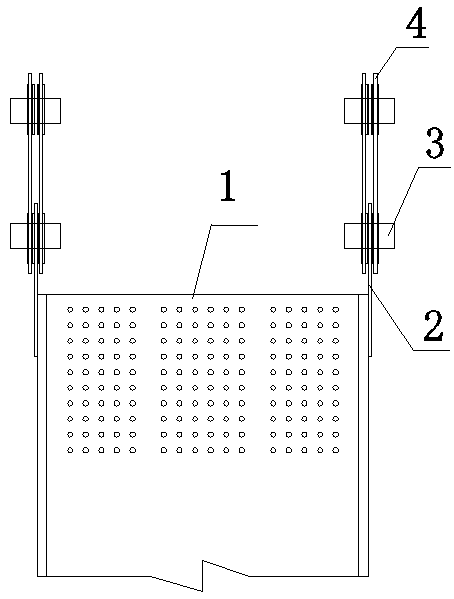

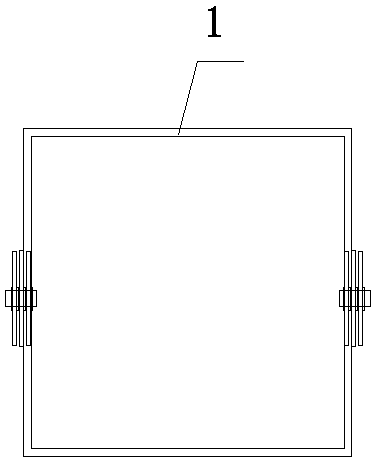

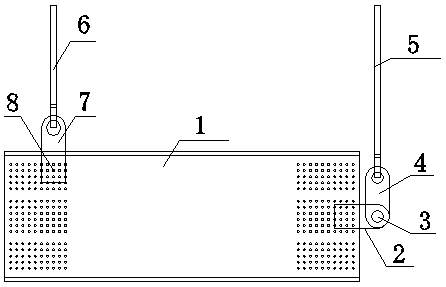

[0021] (1) Before the hoisting of the main chord 1, use high-strength bolts 8 to fix the vertical hoisting lug 2 on both sides of one end of the main chord 1, and the vertical hoisting lug 2 is hinged with a horizontal alignment conversion hanger through the pin shaft 3 4. Use high-strength bolts 8 to fix the horizontal alignment lug 7 on both sides of the other end of the main chord 1;

[0022] (2) Connect the vertical hoisting sling 5 to the vertical hoisting lug 2 through the horizontal alignment conversion hanger 4;

[0023] (3) Vertical hoisting: Lift the vertical hoisting sling 5 so that the main chord 1 vertically pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com