Large-span bridge steel girder closing construction method

A large-span and closing technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of high closing precision requirements, difficult construction, and many closing positions, so as to achieve high machining accuracy, reduce construction risks, reduce Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

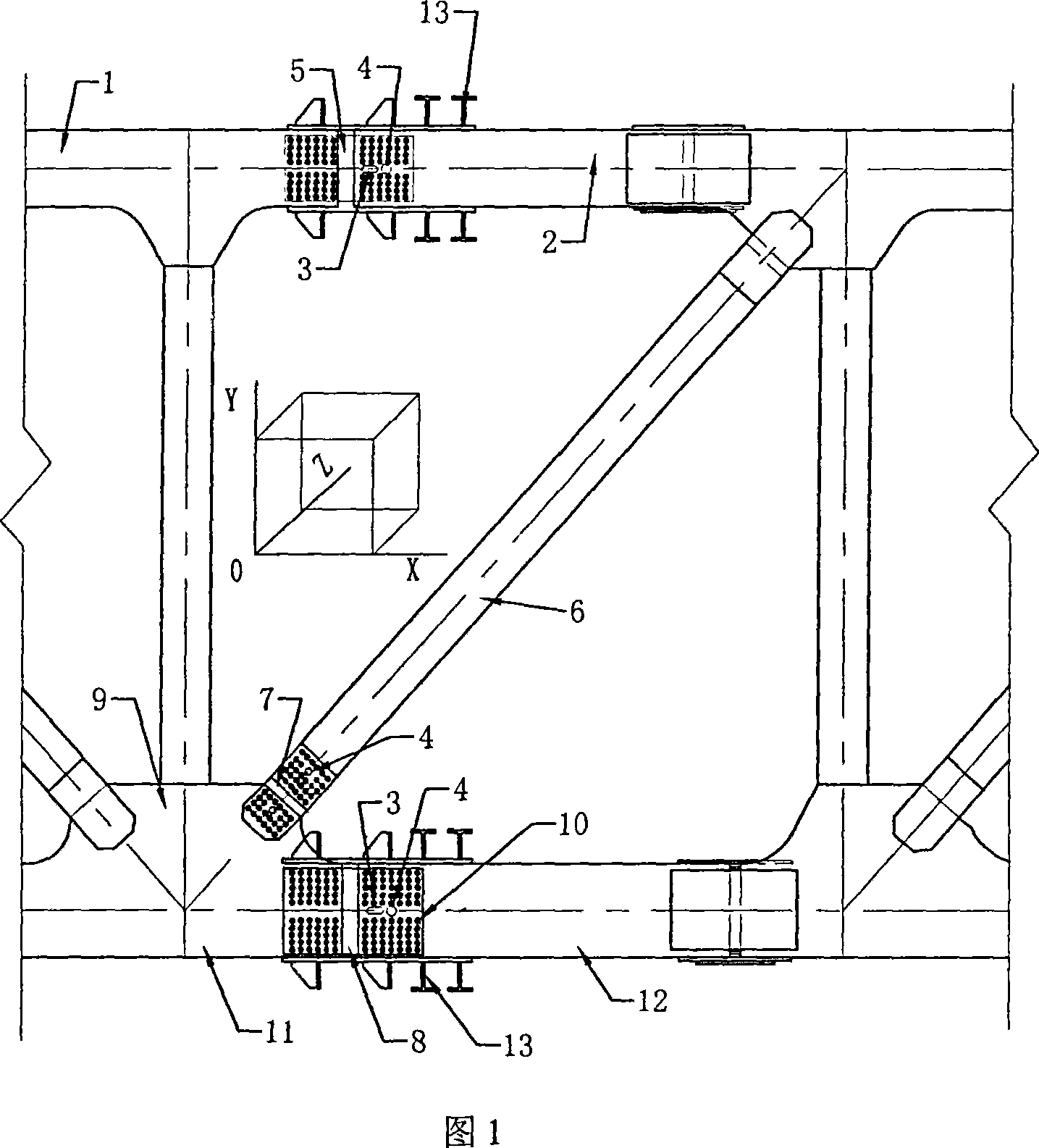

[0027] Embodiment, the steps of the method for the mid-span closure of large-span steel girders,

[0028] (1) According to the idea of closing the winding first and then closing the winding, according to the actual measurement, the deviation in the Z direction is not large, and a 10-ton reverse chain puller is hung between the closing points A28 and AA28, E28 and EE28, and the closing point on the upstream side The bias weight between AA25' and AA26' is about 160 tons, and the elastic cable on the downstream side of the 11# pier is loosened by 40 tons, and the deviation of the lower chord is obviously improved. Upstream and downstream in Z direction - 15 mm, upstream in X direction - 16 mm, downstream - 15 mm, upstream difference in Y direction is 80 mm, and downstream difference is 21 mm.

[0029] (2) In order to make the chord close as soon as possible, the cable adjustment is started on both sides of the closing section. 50 tons of cable is loosened in the upstream of 11#...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com