Cooling tower and construction method thereof

A construction method and cooling tower technology, applied in refrigeration plants, industrial buildings, etc., can solve the problems of heavy structure and long construction period of cooling towers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

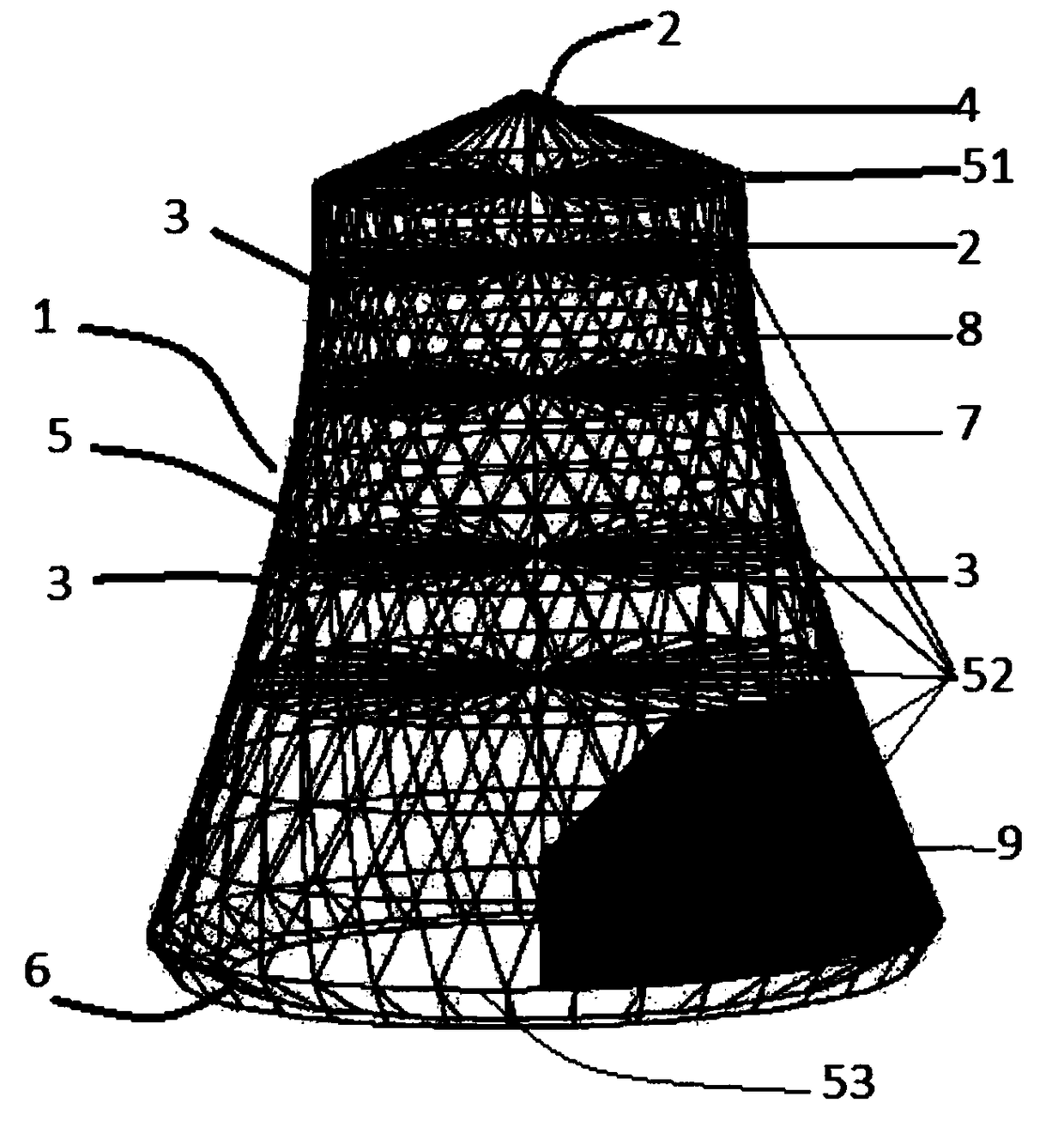

[0062] see figure 1 As shown, the embodiment of the present invention is a cooling tower, which can be applied to new technologies related to the structural design of cooling towers such as laboratories or power plants. Connected tube structure skeleton, the tower column 2 is a rigid column, which is arranged in the tube structure skeleton, and a support beam 3 is connected in the radial direction of the tower column, and the end of the support beam 3 is connected to the tube on the structural skeleton.

[0063]It can be understood that, in this embodiment, the tower tube refers to the facade structure of the cooling tower, including a tube top and a tube body, and the frame of the tube structure includes the frame of the above-mentioned structure. In an ordinary cooling tower, generally a chimney is installed separately on the tower, and a smoke heat exchanger is also required to occupy the land area. In order to improve the utilization rate of the land space and simplify th...

Embodiment 2

[0083] An embodiment of the present invention is applied to a construction method for the cooling tower described in Embodiment 1, comprising steps:

[0084] Tower column construction and tower tube construction;

[0085] The tower column construction includes: compacting the foundation, and vertically fixing the rigid column on the foundation as the tower column;

[0086] The tower construction includes: connecting metal cables in advance to form a tube structure skeleton, and the tube structure skeleton includes a tube top and a tube body;

[0087] Covering the cylinder structure skeleton on the tower column, and connecting the apex of the cylinder top to the top of the tower column;

[0088] A radial support beam is arranged vertically in layers on the tower column, and the end of the support beam is connected to the cylinder body;

[0089] The membrane material is laid on the structural skeleton of the cylinder.

[0090] The embodiment of the present invention is a cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com