Method for producing autoclaved aerated concrete building blocks

A technology of aerated concrete and autoclaved sand, which is applied in the field of concrete block processing, can solve the problems of high pollution, difficult to handle, and many common quality problems, and achieve the effects of avoiding environmental pollution, saving masonry labor, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

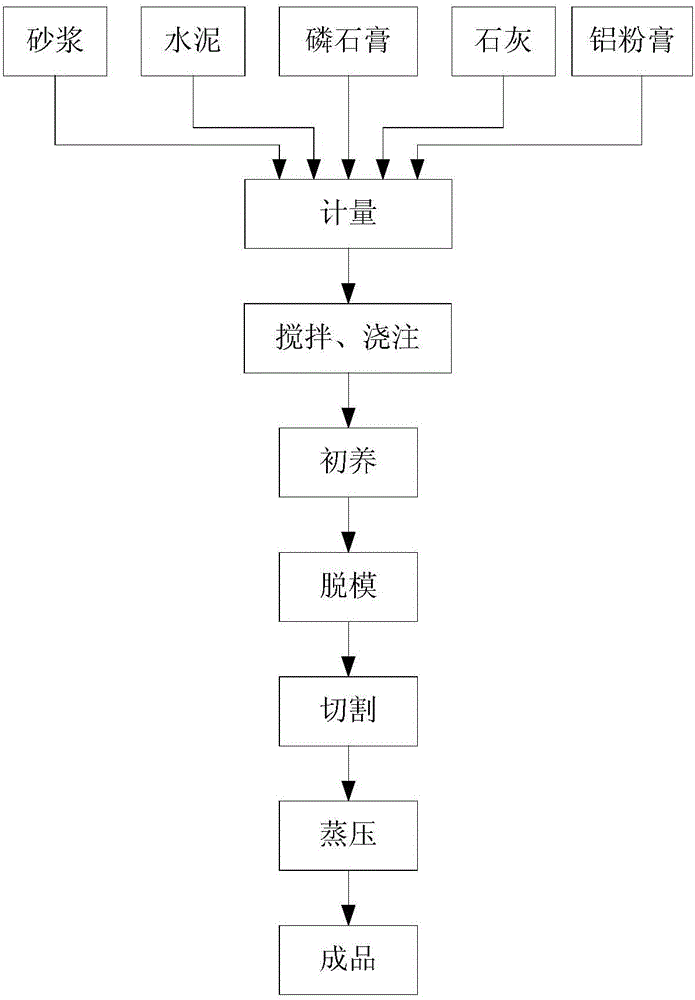

[0018] A method for preparing an autoclaved sand aerated concrete block, characterized in that it comprises the following steps:

[0019] 1) Raw material measurement: select mortar, cement, phosphogypsum, and lime, including 77 parts of mortar, 10 parts of cement, 4 parts of phosphogypsum, and 9 parts of lime;

[0020] 2) Mixing: Put the measured mortar, cement, phosphogypsum and lime into the concrete mixer for mixing;

[0021] 3) Pouring: After stirring, the slurry should reach 40°C before pouring, and the aluminum powder paste suspension is added 4 minutes before the material is poured, and the slurry is cast on the mold;

[0022] 4) Initial curing: After pouring, the mold is steamed and initially solidified with a steam curing trolley, the room temperature is 60°C, and the initial curing time is 3 hours;

[0023] 5) Demoulding and cutting: After the initial maintenance, the mold frame and the green body are hoisted together to the cutting table where the bottom plate of t...

Embodiment 2

[0026] A method for preparing an autoclaved sand aerated concrete block, characterized in that it comprises the following steps:

[0027] 1) Raw material measurement: select mortar, cement, phosphogypsum, and lime, including 75 parts of mortar, 12 parts of cement, 3 parts of phosphogypsum, and 10 parts of lime;

[0028] 2) Mixing: Put the measured mortar, cement, phosphogypsum and lime into the concrete mixer for mixing;

[0029] 3) Pouring: After stirring, the slurry should reach 40°C before pouring, and the aluminum powder paste suspension is added 3 minutes before the material is poured, and the slurry is cast on the mold;

[0030] 4) Initial curing: After pouring, the mold is steamed and initially solidified with a steam curing trolley, the room temperature is 50°C, and the initial curing time is 5 hours;

[0031] 5) Demoulding and cutting: After the initial maintenance, the mold frame and the green body are hoisted together to the cutting table where the bottom plate of ...

Embodiment 3

[0034] A method for preparing an autoclaved sand aerated concrete block, characterized in that it comprises the following steps:

[0035] 1) Raw material measurement: select mortar, cement, phosphogypsum, and lime, including 80 parts of mortar, 8 parts of cement, 5 parts of phosphogypsum, and 7 parts of lime;

[0036] 2) Mixing: Put the measured mortar, cement, phosphogypsum and lime into the concrete mixer for mixing;

[0037] 3) Pouring: After stirring, the slurry should reach 40°C before pouring, and the aluminum powder paste suspension is added 4 minutes before the material is poured, and the slurry is cast on the mold;

[0038] 4) Initial curing: After pouring, the mold is steamed and initially solidified with a steam curing trolley, the room temperature is 70°C, and the initial curing time is 3 hours;

[0039] 5) Demoulding and cutting: After the initial maintenance, the mold frame and the green body are hoisted together to the cutting table where the bottom plate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com