Light energy-conservation large-module combined exterior wall and method of manufacturing the same

A large modular and combined technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of cumbersome construction, many wet operations, cracks, etc., and achieve the effects of simplifying the calibration and positioning process, enhancing the thermal insulation effect, and increasing the seismic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

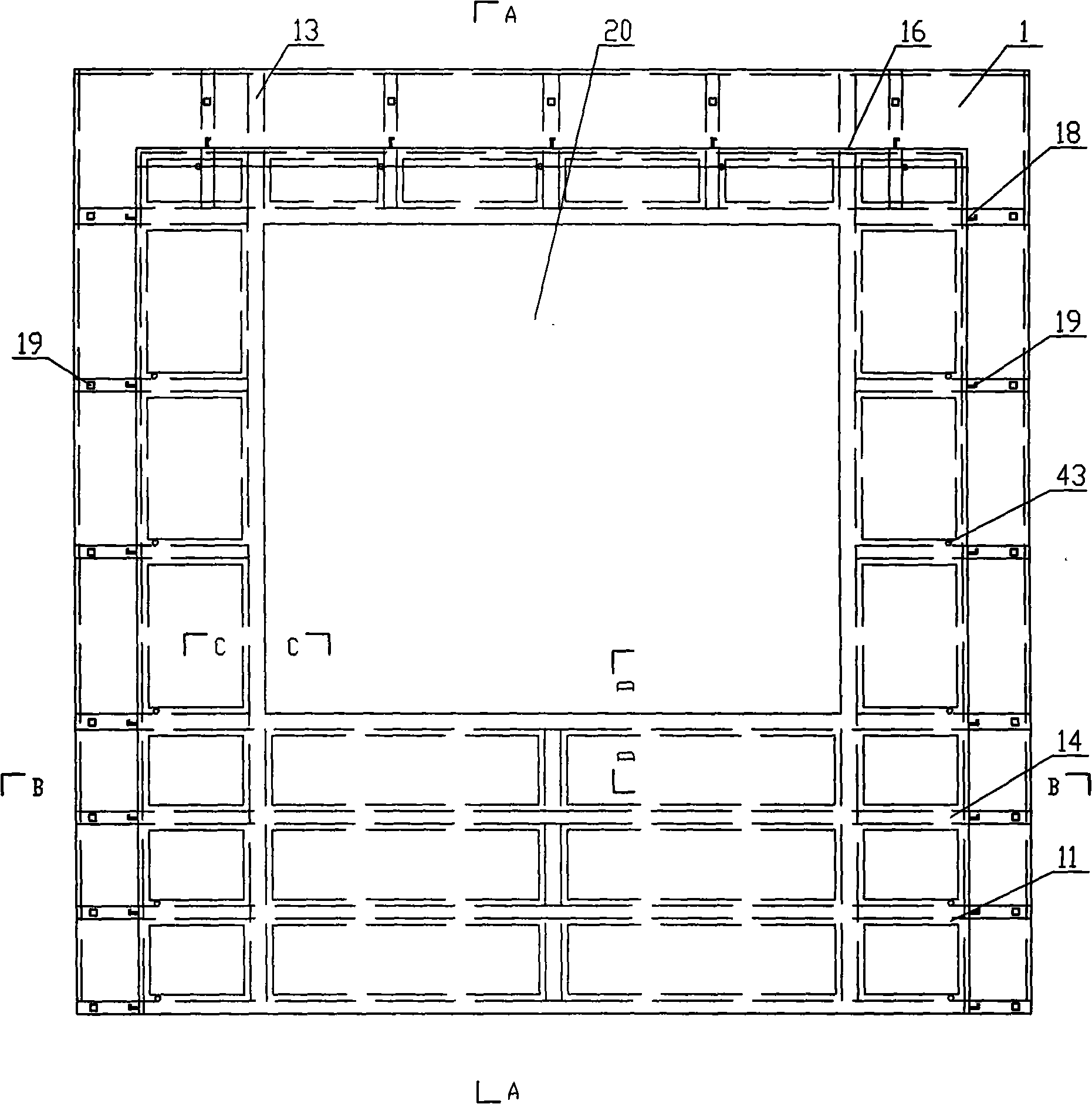

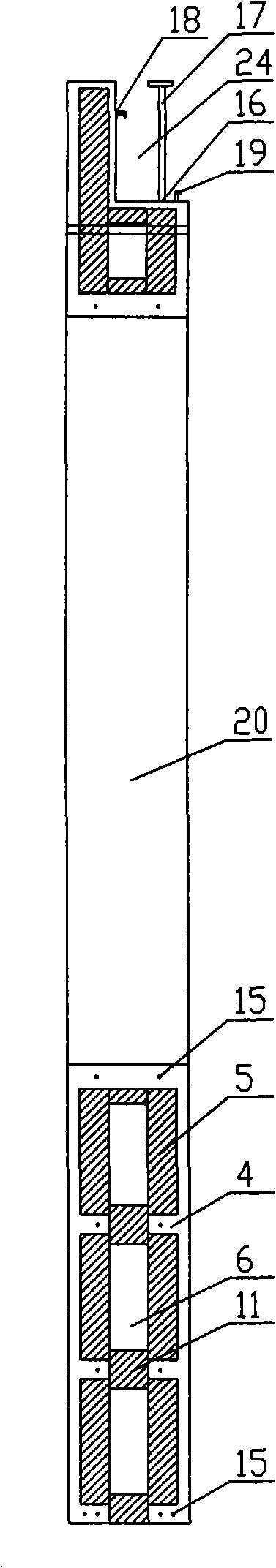

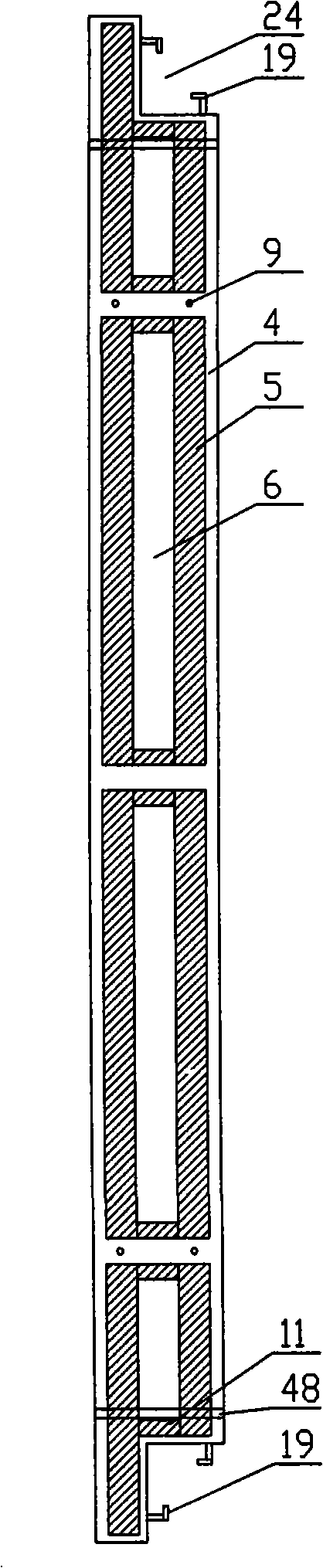

[0030] Such as figure 1 The present invention shown: the height of the outer wall is the floor height minus 10MM, and the width is the distance between the two axes of the column in the building minus 10MM. The 10MM is the gap between the wall installation and adjustment. The total thickness of the wall is 250MM. The wall is filled with lightweight thermal insulation mortar. The outer wall is composed of two strong surface layers on the outer walls. The structure of the layer cavity is composed of steel mesh in the surface layer of the two outer walls, and the cage is positioned on the surface layer, and the ribs connecting the two layers are connected by steel grid frame and steel frame, and the steel mesh in the surface layer is spot welded and bound to form a wall. The three-dimensional steel mesh reinforcement frame, the steel mesh is 50×50×φ2MM spot-welded steel mesh, the steel frame is φ12 gong steel, the steel frame is also the lifting point of the wall, and the end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com