Juice press

A technology of juice press and pressing rod, which is applied in the field of juice press, and can solve the problems of incomplete pressing, high price and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

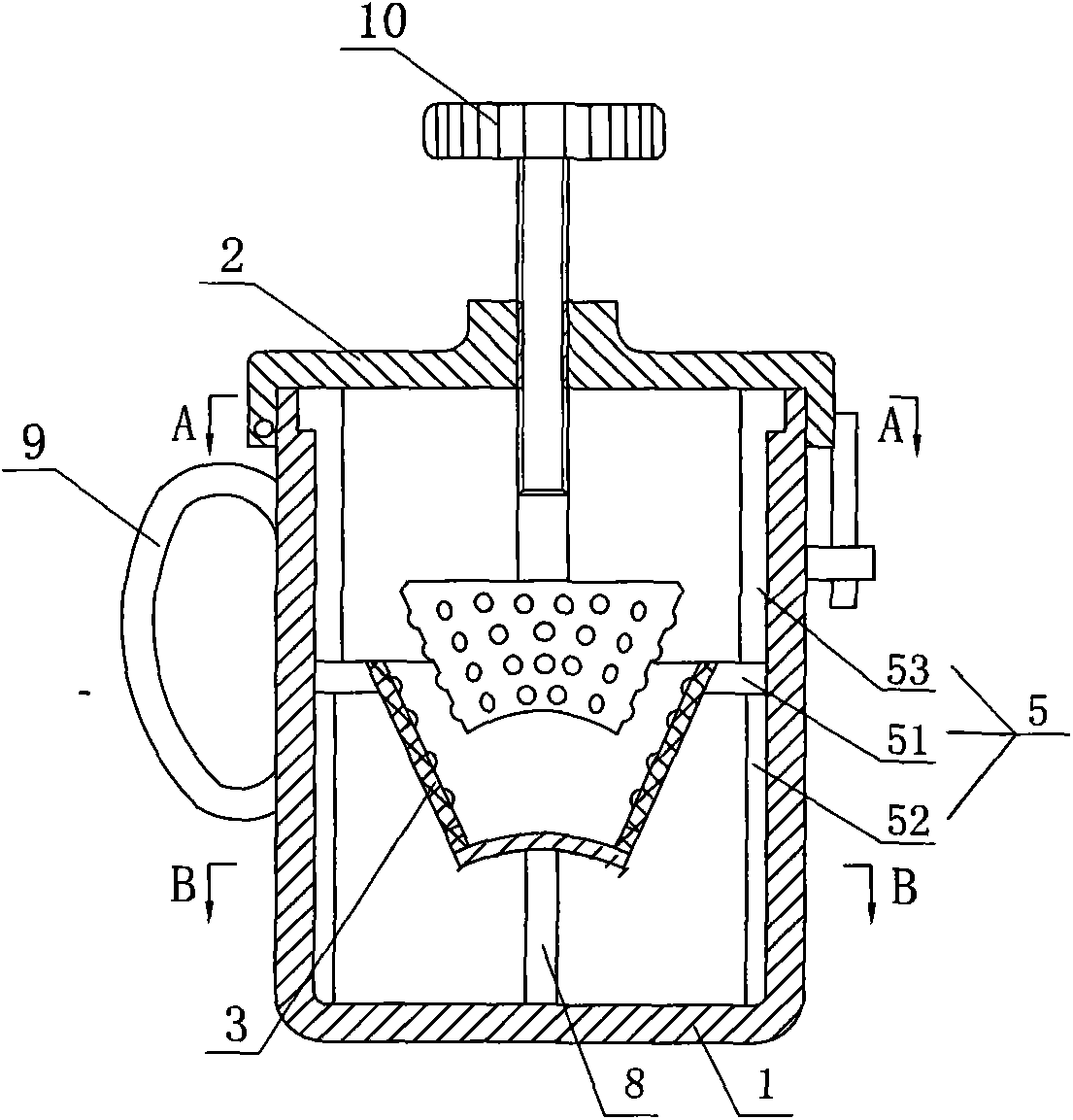

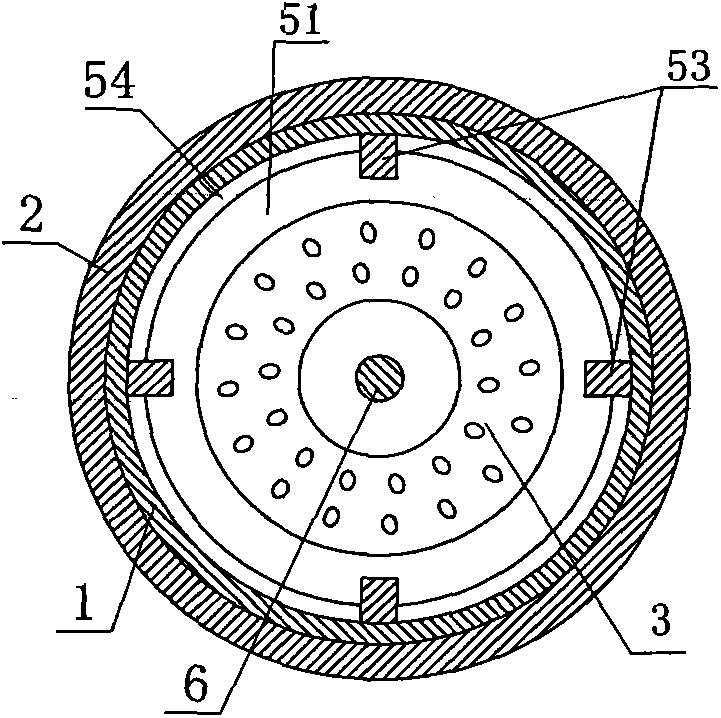

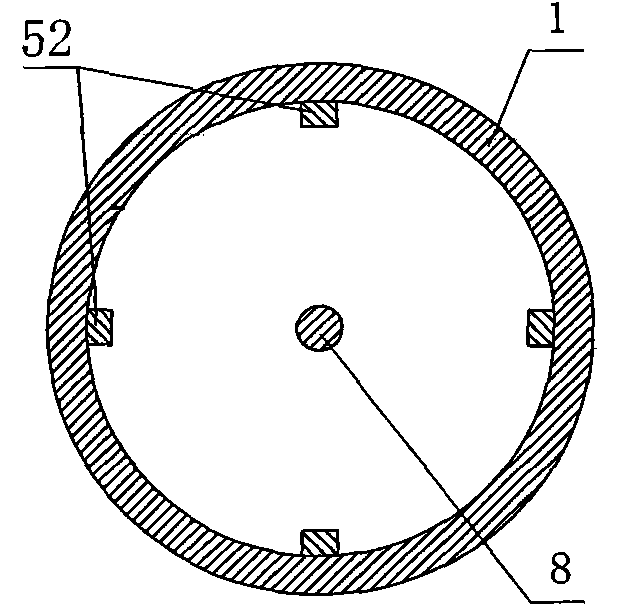

[0014] Such as figure 1 The juice press shown includes a tank body 1 made of stainless steel with an open top. A handle 9 may be provided on the tank body 1, and the top of the tank body 1 is hinged with an upper part that is locked by a locking device. The cover 2, the locking device is an existing mechanism, which will not be repeated here. The inner cavity of the tank 1 is equipped with a filter 3 with a small bottom and a conical arrangement. The top of the filter 3 is open and the bottom opening passes upwards. The protruding arc-shaped bottom plate 4 is sealed, and the open edge of the top of the filter screen 3 is connected to the inner cavity of the tank body 1 through a bracket 5. The upper cover 2 is screwed with a spinning rod 6 extending into the tank body 1. The spinning rod The inward end of 6 is fixedly connected with a spinning head 7 adapted to the shape of the inner cavity of the filter screen. The bottom surface of the spinning head 7 is a concave surface corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com