Spiral Welding Mesh Tube Welding Machine

A technology of spiral welding and mesh, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of large steel plate width, low manufacturing accuracy, and difficult to guarantee diameter, and achieve accurate tolerance size, material saving, and thickness reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is taken as an example to produce the following products, and the technical scheme of the present invention is further described:

[0018] Diameter φ(mm) Wall thickness δ(mm) Punching φ(mm) Hole spacing B(mm) punching arrangement F% material 10.8 0.8 2.38 4 △ 32 304

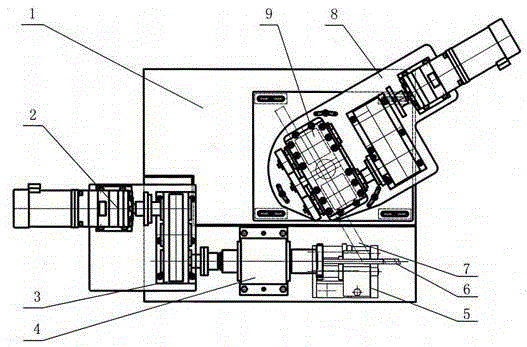

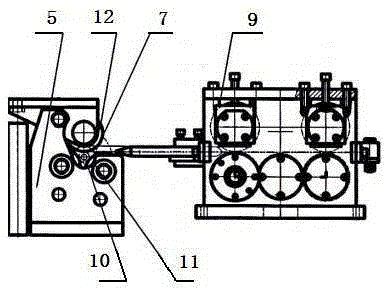

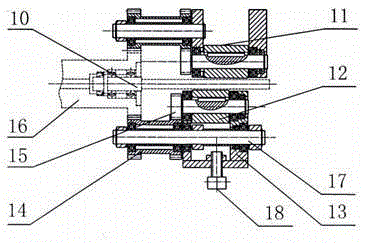

[0019] A coil welding machine for spiral welded mesh pipe, mainly composed of a platform 1, a motor 2, a reducer 3, a spindle box 4, a forming coil welding mechanism 5 and a feeding mechanism 9, and the platform 1 is equipped with a motor 2, a reducer 3, The spindle box 4, the forming roll welding mechanism 5, the feeding mechanism 9 and the feeding mechanism rotating platform 8; the motor 2, the reducer 3, the spindle box 4, and the forming roll welding mechanism 5 are connected in sequence; the forming roll welding mechanism 5 is connected with the feeding mechanism 9 and The rotating platforms 8 of the feeding mechanism are connected in sequence....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com