Unloading Composite Guide Rail Structure of Inclined Beam

A beam and guide rail technology, applied in the field of machine tools, can solve the problems that the bearing capacity of the composite guide rail is not large enough, the effect of use is not ideal, and the movement is not stable enough, so as to achieve the effect of large bearing capacity, ideal use effect and structural optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

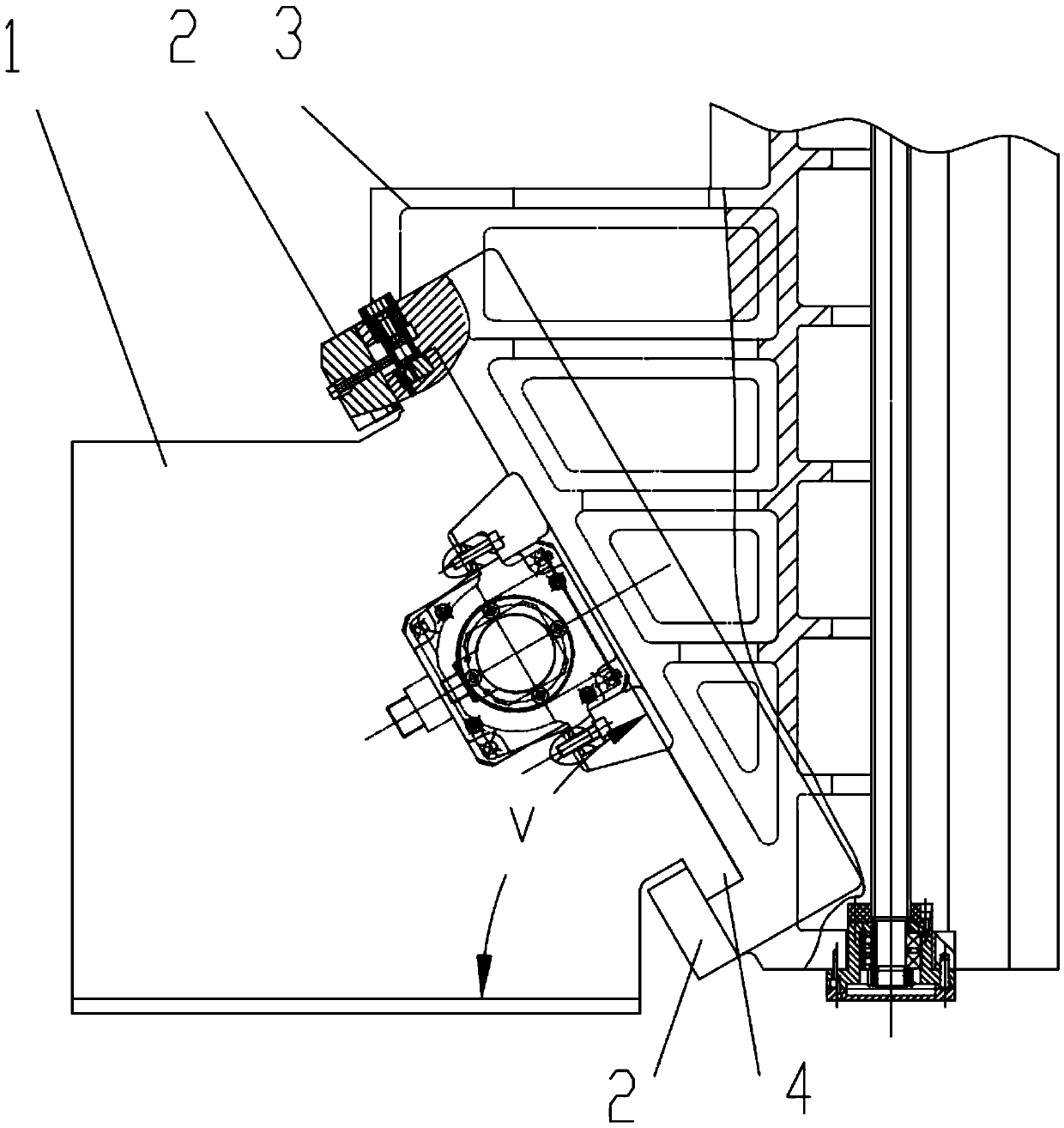

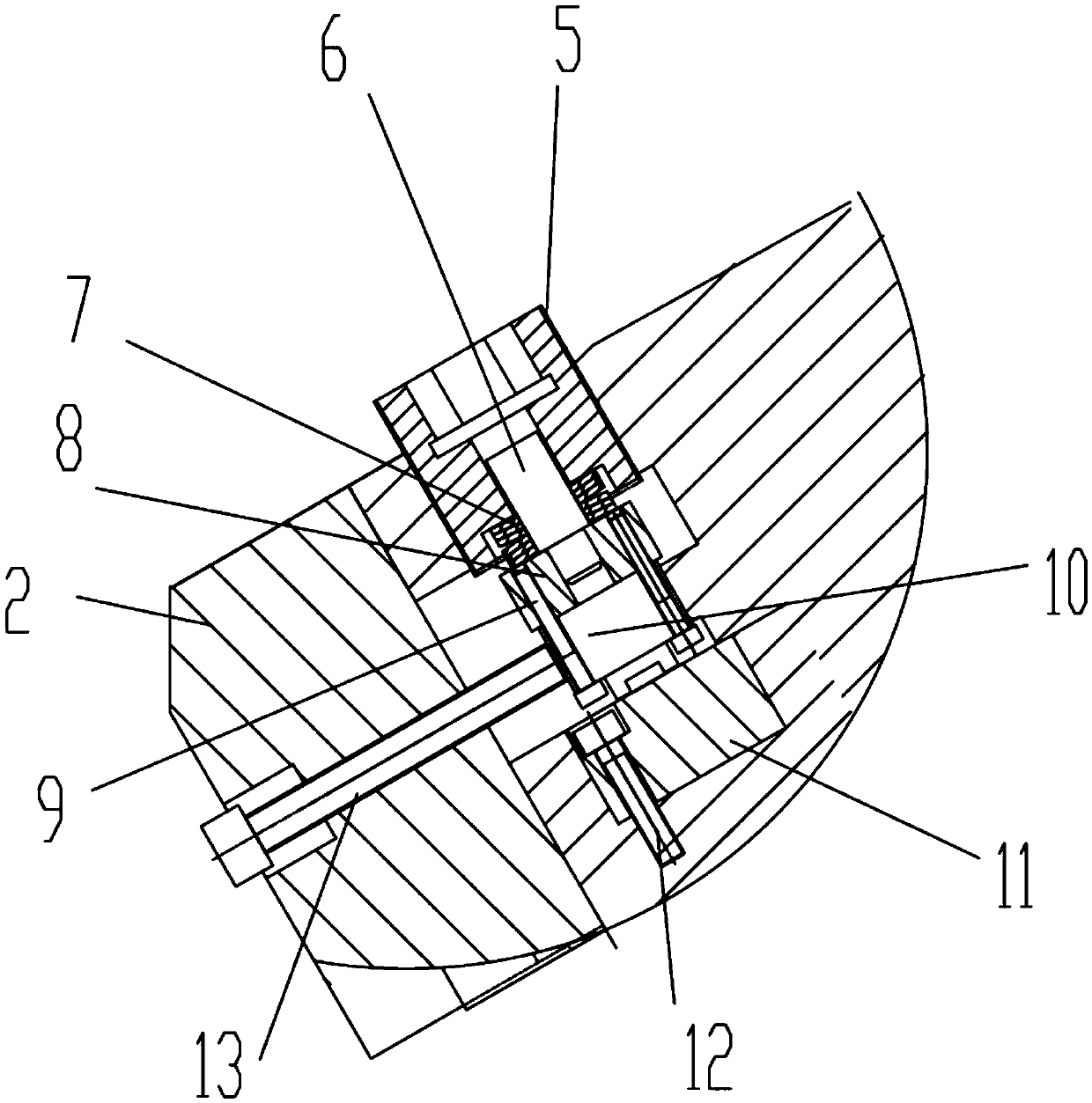

[0021] Embodiments of the present invention, such as figure 1 , figure 2 As shown, the inclined beam unloading composite guideway structure includes the beam, the slide seat 3 in the headstock, the rolling guide pair and the slide guide pair arranged between the beam and the slide seat 3 in the headstock, and the unloading adjustment device; The sliding seat 3 is guided and connected with the beam through the rolling guide rail pair and the sliding guide rail pair; The connecting side of the connecting side is provided with a cuboid-shaped notch that is recessed obliquely downward and matched with the inclined-plane block 4, and the rolling guide rail pair is arranged between the upper end surface of the inclined-plane block 4 and the upper top surface of the notch; the sliding guide rail pair is arranged on the inclined-plane block 4 between the slope of the gap and the slope of the notch.

[0022] The supporting guide rail of the sliding guide rail pair is the convex side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com