Molds for the production of airbag covers

A technology of airbag cover and mold, which is applied in the field of molds, and can solve problems such as complicated operation, reduced production efficiency, and large mold volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

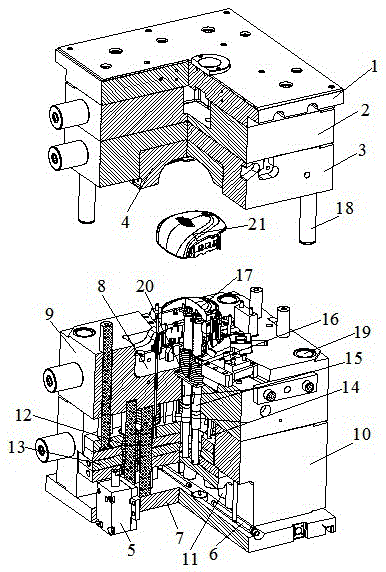

[0014] see figure 1 , the mold suitable for producing the airbag cover of the present invention includes: an upper mold, a lower mold and a cavity between the two. Specifically, the upper mold is provided in sequence from top to bottom: an upper fixed plate 1, a hot runner plate 2, and a female template 3, and a female mold core 4 is arranged in the female template 3; the lower mold is provided in sequence from bottom to top: an oil pressure cylinder 5. A lower fixing plate 7 provided with a cooling water pipe 6, and a male template 9 provided with a male mold core 8. Accommodating space is formed between the lower fixed plate 7 and the male template 9 and the periphery is supported by the die foot 10, as figure 1 As shown, a supporting column 11, a ejector plate guide column 12, an ejector plate 13, an ejector pin 14, and an ejector ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com