A gripping mechanism for circular thin plate processing for new energy vehicles

A new energy vehicle, grabbing mechanism technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as troublesome manual feeding, low efficiency, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

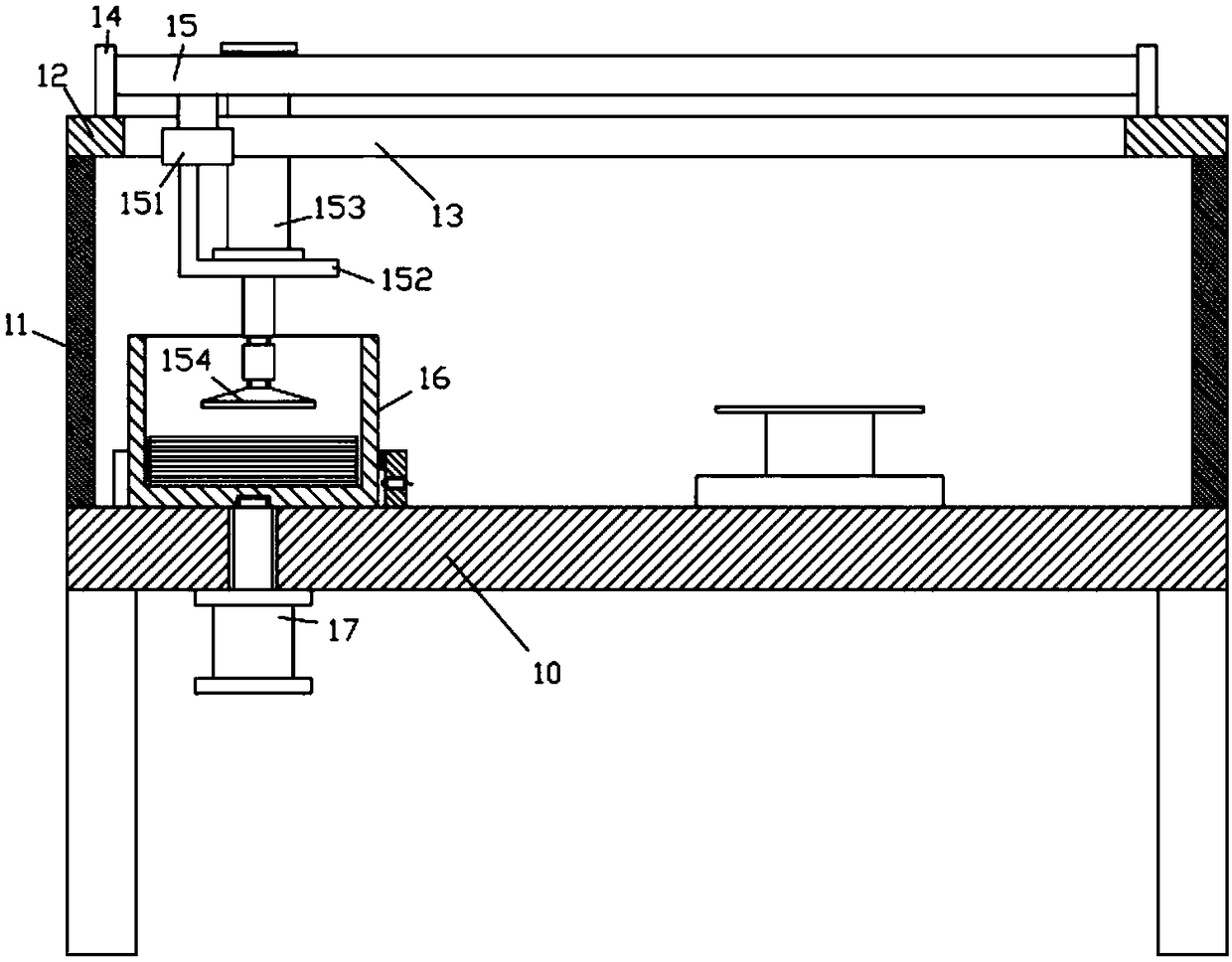

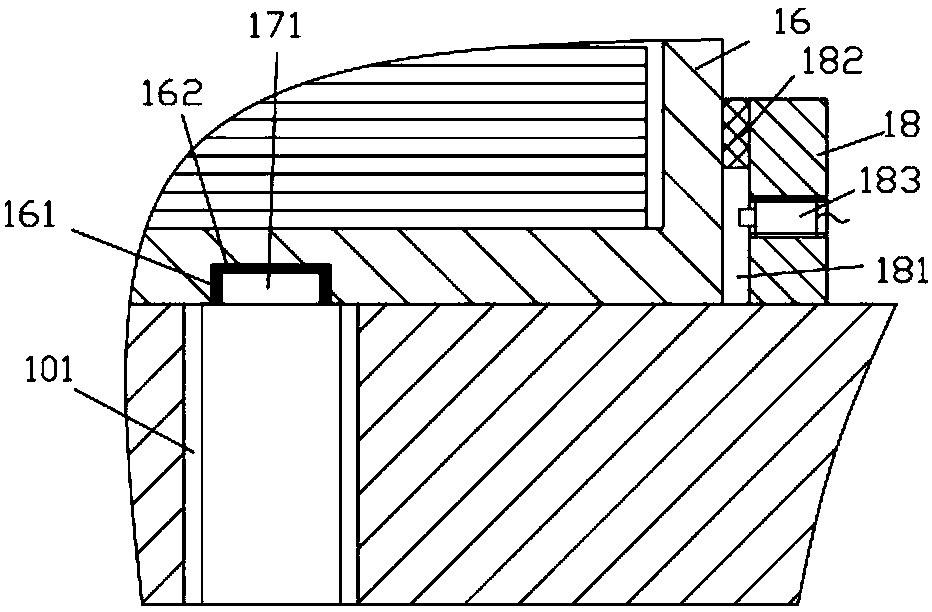

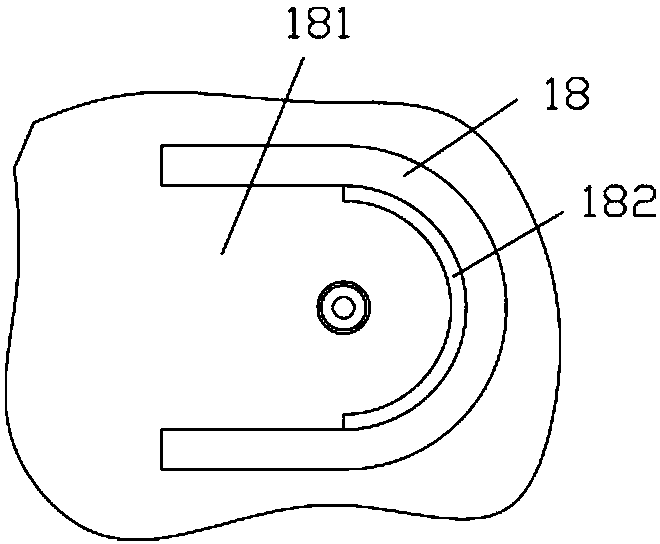

[0017] Example, see as Figure 1 to 3 As shown, a circular sheet processing and grasping mechanism for new energy vehicles includes a frame 10, the left and right sides of the top plate of the frame 10 are fixed with vertical support plates 11, and the upper plate body 12 is fixed on two vertical On the top surface of the straight support plate 11, the middle part of the upper plate body 12 has a moving through groove 13, the left and right ends of the top surface of the upper plate body 12 are fixed with connecting plates 14, and the two ends of the rodless cylinder 15 are fixed in two connecting On the plate 14, a movable connecting block 151 is fixed on the moving block of the rodless cylinder 15, and the movable connecting block 151 is inserted and sleeved in the moving through groove 13. The bottom surface of the movable connecting block 151 is fixed with a connecting frame 152, and the bottom of the connecting frame 152 A telescopic cylinder 153 is fixed. The push rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com