Squeegee Adaptive Mechanism for Solar Cell Screen Printing Machine and Solar Cell Screen Printing Machine

A technology for screen printing machines and solar cells, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as unbalanced printing pressure, high equipment failure rate, and reduced printing quality, and achieve grid line quality Improvement, uniform contact, and reduced cell loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

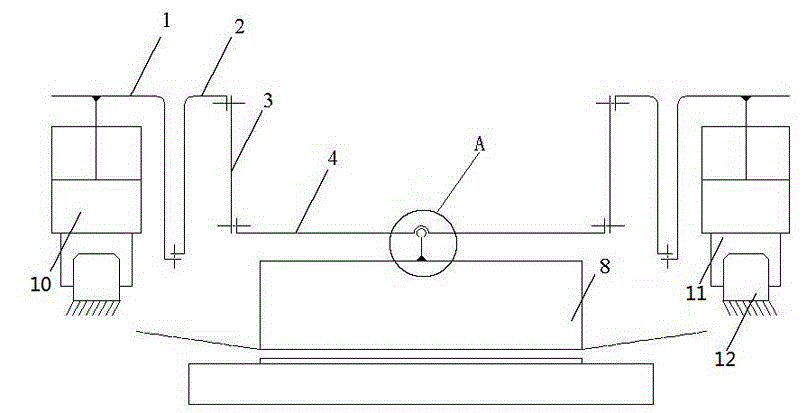

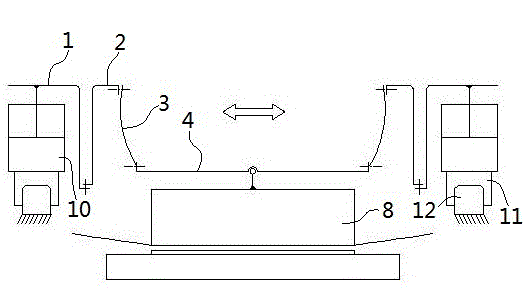

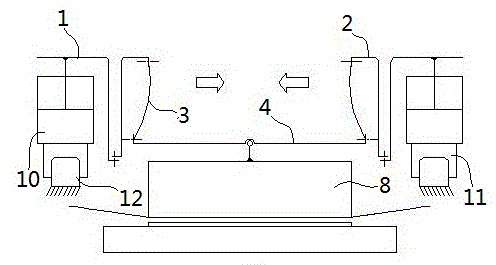

[0055] A scraper self-adaptive mechanism suitable for solar cell screen printing machine, such as figure 1 As shown, it is composed of a cylinder connecting plate 1, a Z-shaped transition piece 2, an elastic connecting piece 3, an intermediate support beam 4, a longitudinal connecting seat 6, a shaft 7, a scraper assembly 8, and a lock nut 9. Both ends of the scraper self-adaptive mechanism are provided with elastic connecting pieces 3, one end of the elastic connecting piece 3 is fixed to the end of the middle support beam through threads, and the other end is connected with the cylinder connecting plate through a Z-shaped transition piece. The elastic connecting piece 3 is symmetrical about the midpoint of the middle support beam 4 .

[0056] A Z-shaped transition piece 2 is arranged between the elastic connecting piece 3 and the cylinder connecting plate 1 , and the transition piece connects the cylinder connecting plate 1 and the elastic connecting piece 3 together through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com