Continuous hydrolysis system for preparation of glyphosate by glycine method

A technology of glycine and glyphosate, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problem of failure to achieve the desired effect, failure to realize the continuous reaction of the whole process of hydrolysis, etc. problems, to achieve remarkable energy-saving effects, easy control, and continuous energy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

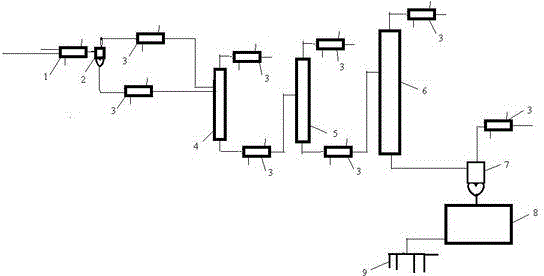

[0040] The continuous hydrolysis system for preparing glyphosate by the glycine method is characterized in that it includes a mixing reactor, a gas-liquid separator, a heat exchanger, a methylal recovery tower, a methanol recovery tower, a hydrolysis tower, a flash evaporator, an insulated storage tank, a crystallization still, the mixed reactor is connected to the gas-liquid separator, and the exhaust port and the liquid outlet of the gas-liquid separator are respectively connected to a heat exchanger, and the heat exchanger is connected to the methylal recovery tower; the methylal recovery Tower, methanol recovery tower, hydrolysis tower, flash evaporator, heat preservation storage tank, and crystallization kettle are connected in sequence.

Embodiment 2

[0042] The implementation mode of this embodiment is basically the same as embodiment 1, on this basis:

[0043] The heat exchanger connected to the exhaust port of the gas-liquid separator is connected to the top of the methylal recovery tower, and the heat exchanger connected to the liquid outlet of the gas-liquid separator is connected to the middle of the methylal recovery tower.

Embodiment 3

[0045] The implementation mode of this embodiment is basically the same as embodiment 1, on this basis:

[0046] The mixing reactor of the present invention has a cooling function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com