Steel rail beam anti-skidding surface layer for straddle type single-rail traffic

A straddle-type monorail and steel track beam technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of easy slipping of vehicle tires, increase the friction between the running surface of the track beam and the rubber tires of rail trains, etc., and solve the problem of easy slipping , increasing the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained in conjunction with the drawings:

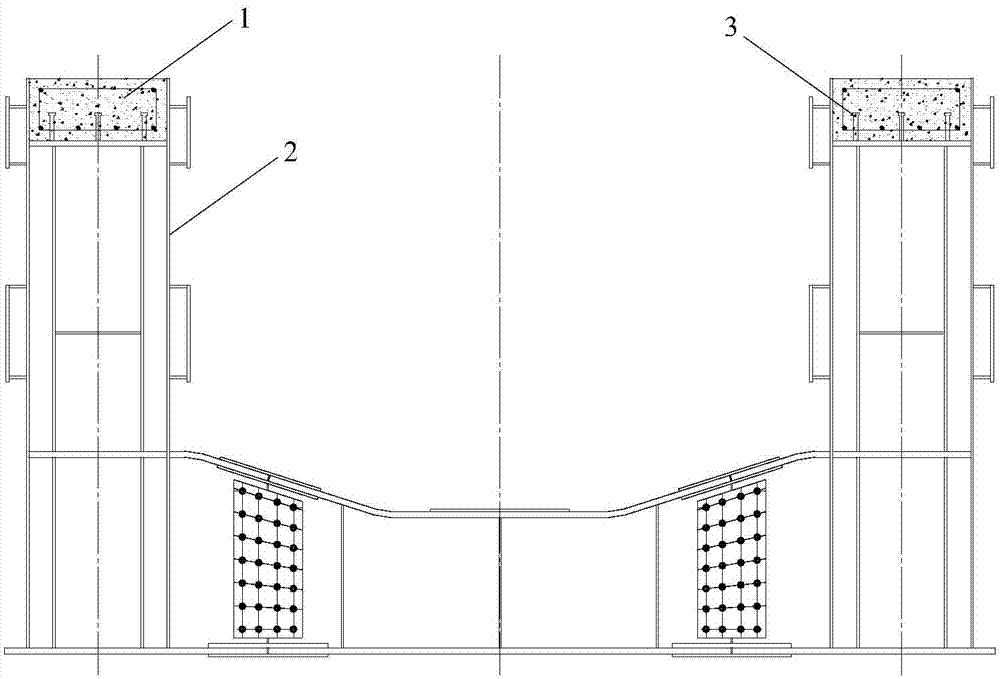

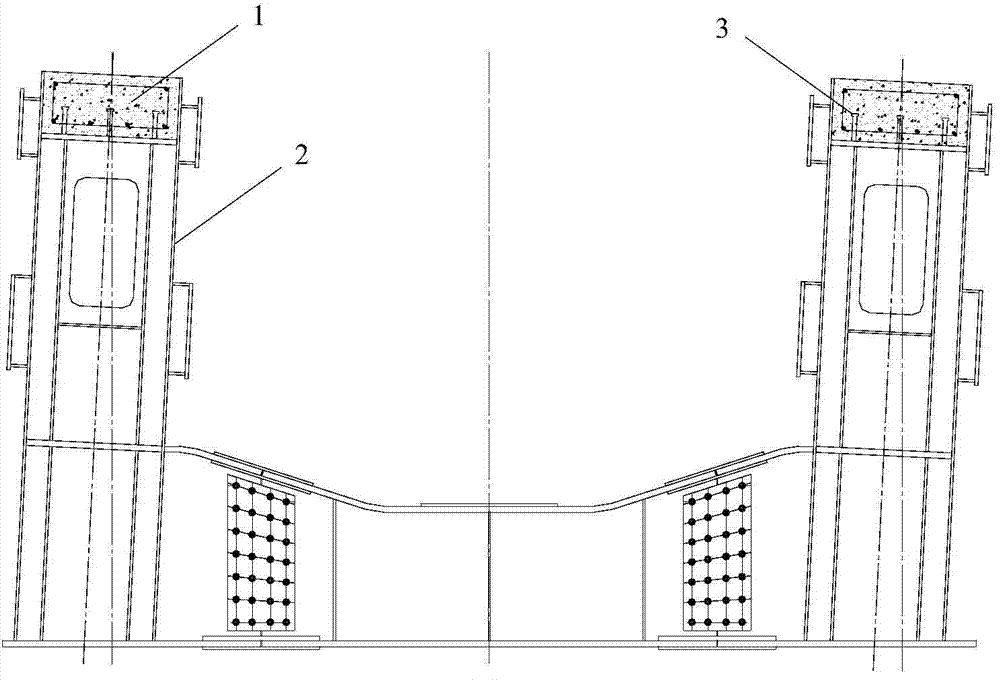

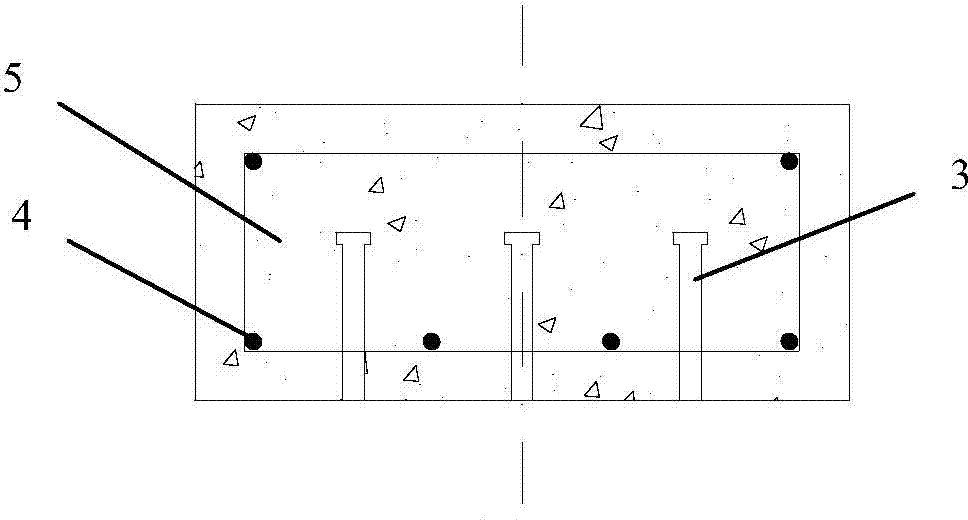

[0014] The anti-skid surface layer of the straddle-type monorail transportation steel track beam is composed of reinforced concrete 1. The anti-skid surface layer is located on the running surface of the steel track beam. The anti-skid surface layer of reinforced concrete 1 and the steel box girder 2 are connected by a shear connector 3 .

[0015] The thickness of the anti-skid surface layer is 0.1 m to 1.0 m, and the anti-skid surface layer is equipped with steel bars 4 to limit the crack width of the concrete 5 and prevent the concrete 5 from falling off.

[0016] Application of anti-skid surface of straddle monorail transportation steel track beam

[0017] The length of the steel track beam is 50m, the beam height is 3.2m, the beam width is 0.85m, the anti-slip surface concrete grade is C40, the thickness is 0.3m, and the steel bar is HRB400Φ20.

[0018] Place and bind steel bars 4 on the runn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com