Steel lead laminated ring damper

A technology of damper and lamination, which is applied in the direction of building components, earthquake resistance, etc., can solve the problems of complex structure of the invention, and the energy consumption of the damper can not be well used in the shear force part, so as to reduce the earthquake response and make the installation simple , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

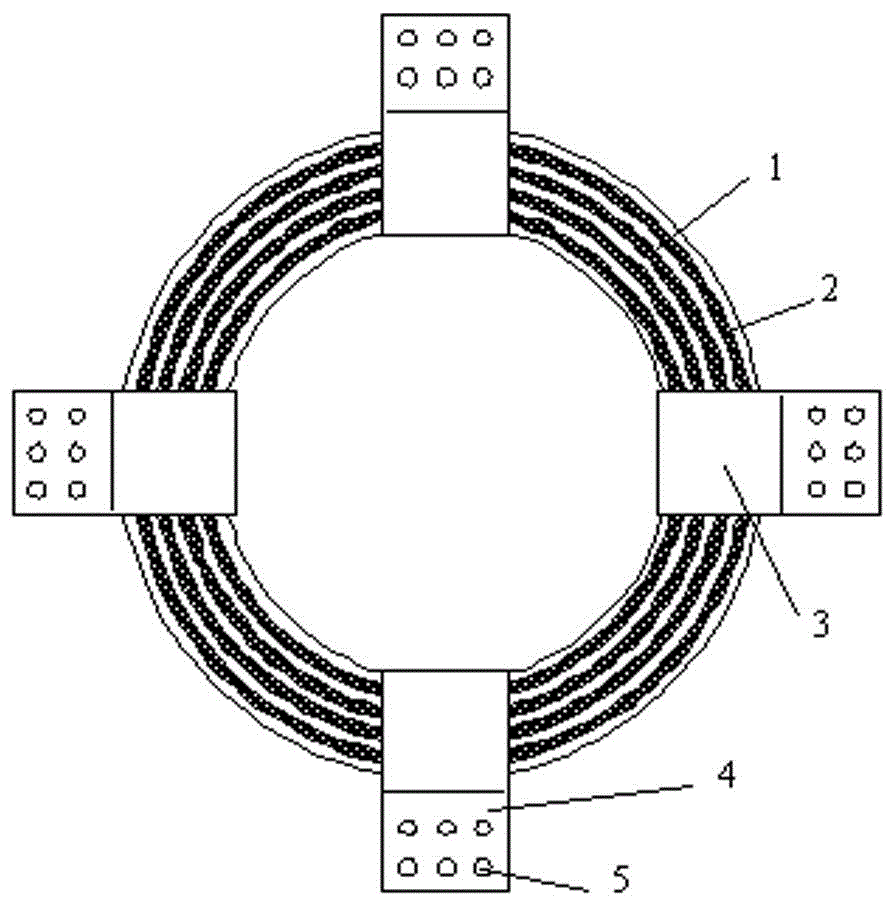

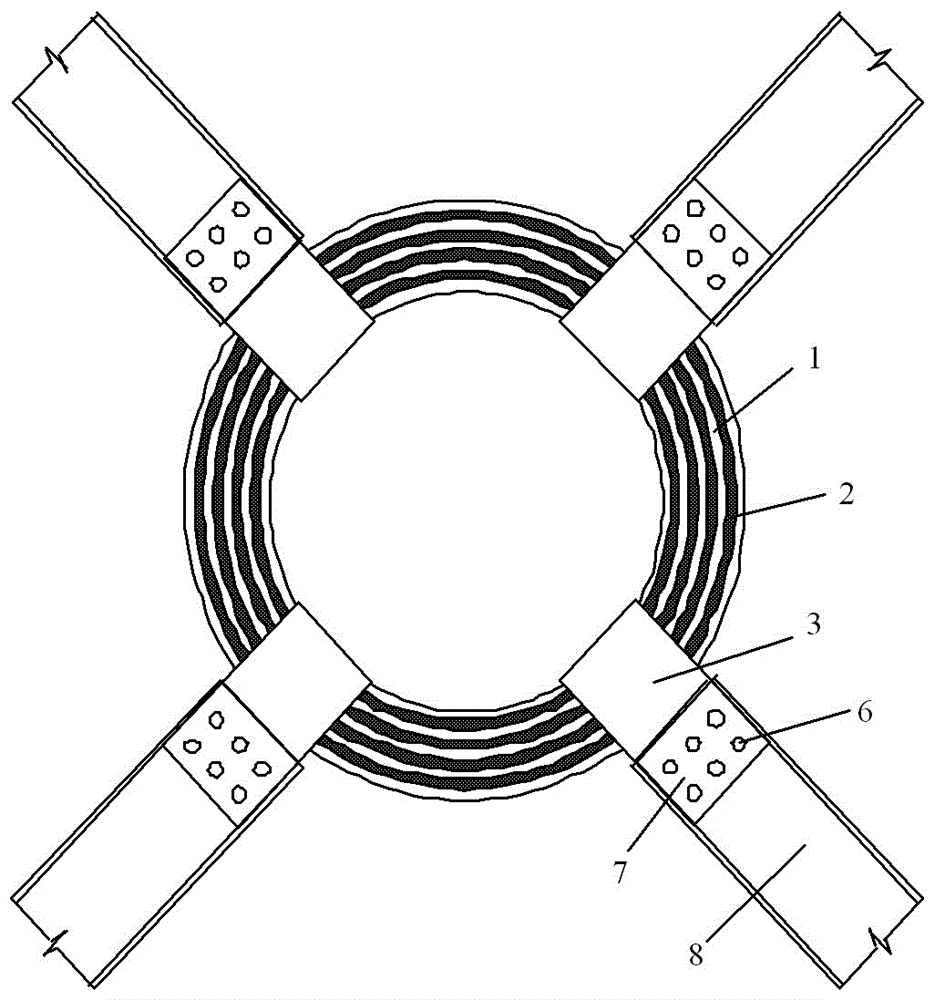

[0020] Such as figure 1 , 2 The steel-lead laminated annular damper shown includes a mild steel energy-dissipating cylinder 1, a lead energy-dissipating cylinder 2, a connecting plate 3, a fixing plate 4, screw holes 5, bolts 6, backing plates 7, and steel supports 8. The mild steel energy dissipation cylinder 1 and the lead energy dissipation cylinder 2 are alternately stacked to form the energy dissipation cylinder; the square cylindrical connection plate 3 hoops the energy dissipation part of the energy dissipation cylinder, and the four connection plates 3 are relatively The centers are symmetrical in pairs and form an "X" shape, and each fixing plate 4 with screw holes 5 is fixedly connected with each connecting plate 3 respectively. Each fixing plate 4 is respectively connected with each steel support 8 by bolts 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com