Apparatus and method for high-altitude horizontal transportation of pressed metal roof panels

A technology for horizontal transportation and metal house, which is applied in the field of high-altitude horizontal transportation devices for profiled metal roof panels, can solve the problems of roof panel deformation and damage, high labor intensity, and a large number of horizontal transportation personnel, and achieves the goal of reducing the number and labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] High-altitude horizontal transport device for pressed metal roof panels

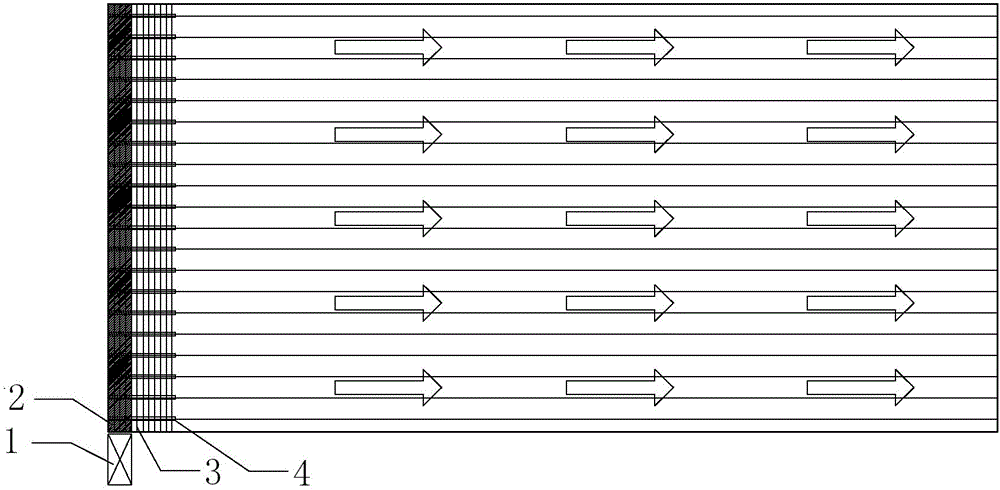

[0046] figure 1 It is a layout diagram of the high-altitude horizontal transportation device for the pressed metal roof panel of the present invention. As shown in the figure, the high-altitude horizontal transportation device for the pressed metal roof panel, the metal roof panel forming machine is installed on the outside of the high-altitude roof cornice, and the metal roof panel is pressed and formed on the roof purlin. The horizontal transportation device includes an operating platform , a longitudinal track plate and a transport trolley, characterized in that:

[0047] The operation platform is a transportation platform formed by fully paving wood boards on the profiled metal roof panels that have been installed on the roof purlins at the initial stage;

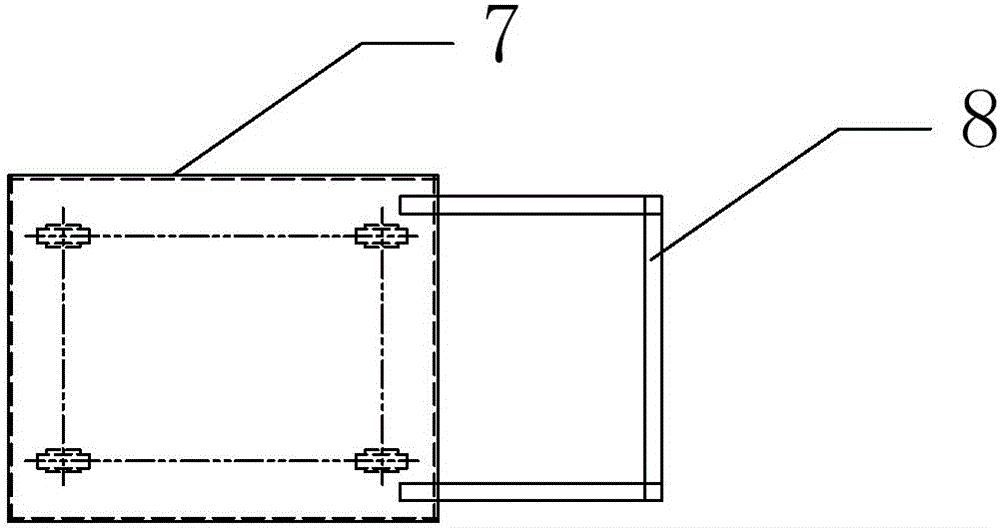

[0048] Figure 7 It is a schematic cross-sectional view of the 475 type longitudinal track plate of the present invention. The longitu...

Embodiment 2

[0053] High-altitude horizontal transportation method of pressed metal roof panels

[0054] A method for high-altitude horizontal transportation of pressed metal roof panels. The metal roof panel forming machine is installed outside the cornice of the high-altitude roof, and the metal roof panels are pressed and formed on the roof purlins. The method is characterized in that it includes the following steps:

[0055] a. Prefabricated roof panel fixing seat

[0056]Use a 2mm thick, 36mm wide, and 60mm long galvanized steel plate to press into a "Π" shaped roof panel fixing seat, with two φ6mm bolts on the side;

[0057] b. Prefabricated longitudinal track slabs

[0058] Figure 8 It is a schematic cross-sectional view of the 713 type longitudinal track plate of the present invention. Press the 1.2mm thick color steel plate to make the 713 type longitudinal track plate with a width of 713mm;

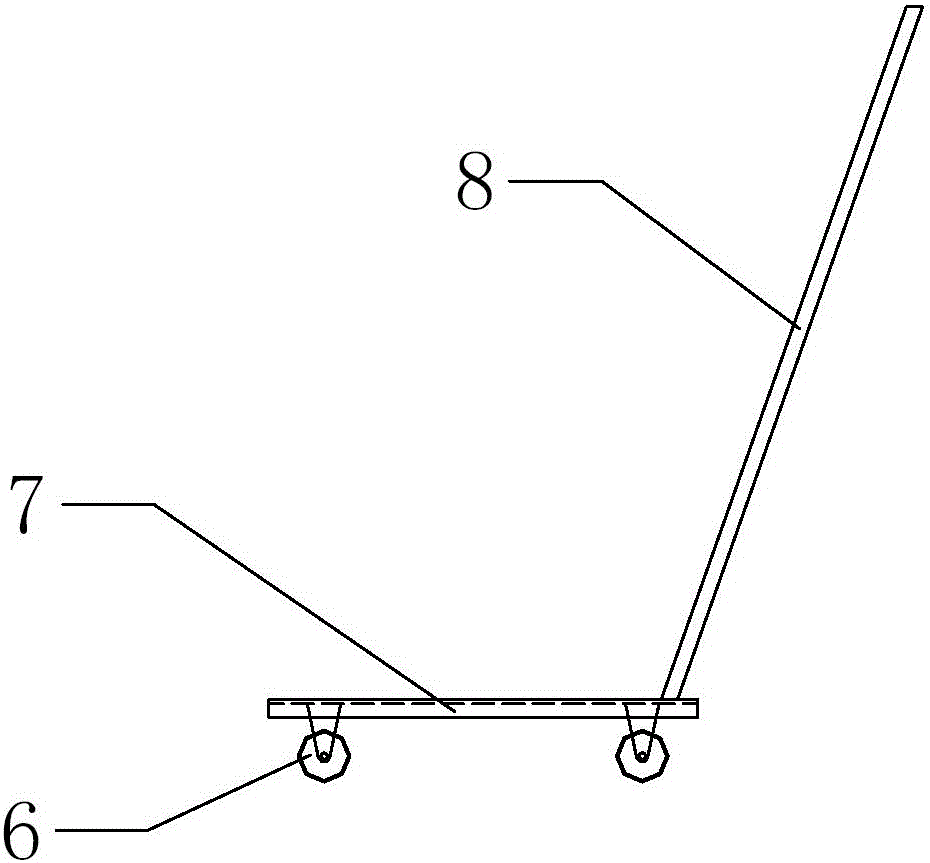

[0059] c. Prefabricated transport trolley

[0060] The transport trolley includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com