Electric hydraulic filter throttling valve

A throttle valve and hydraulic technology, applied in the field of hydraulic throttle valve, can solve the problems of easy contamination of liquid, low adjustment accuracy, damaged hydraulic components, etc., achieve accurate flow, simple disassembly, and prevent damage from multiple openings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

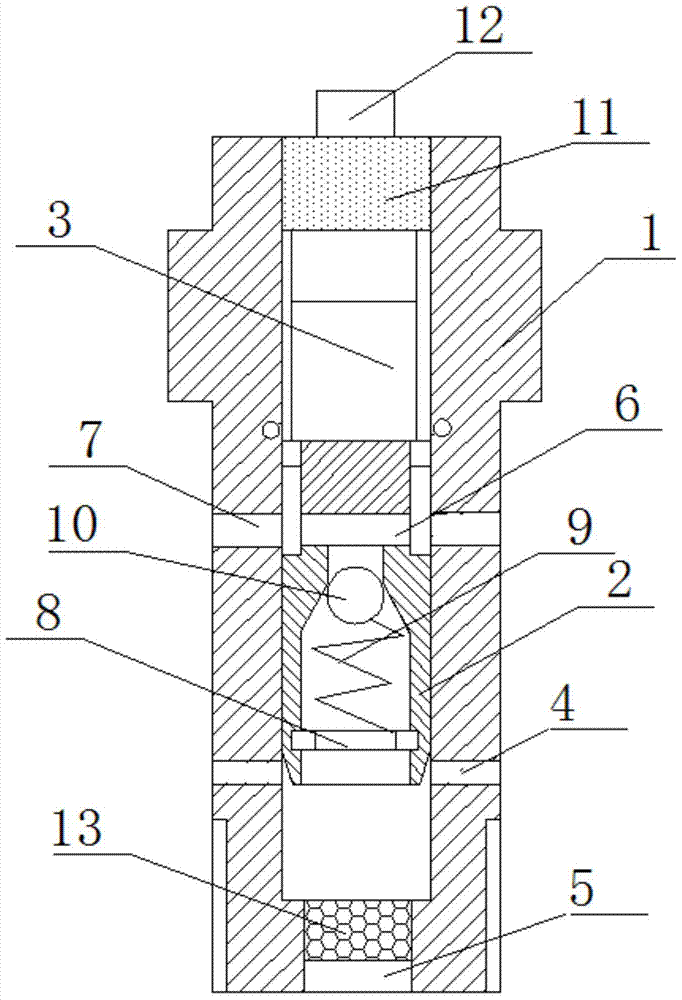

[0015] An electro-hydraulic filter throttle valve in this embodiment, such as figure 1 As shown, it includes a valve body, a valve core and an adjusting rod. The valve core is arranged in the valve body. The outer diameter of the upper end of the valve body is greater than the outer diameter of the part below the head. Some parts are provided with external threads, and more than one transverse channel is provided on the valve wall below the head of the valve body. The transverse channel is a liquid outlet channel. The valve body runs through up and down. One end of the core, the free end of the valve core points to the liquid inlet channel at the opening of the lower part of the valve body, and also includes a filter, a rotary motor and a screw propeller, the rotary motor and the screw propeller are connected in transmission, and the screw propeller The propeller is set in the valve body, and the actuating rod of the screw propeller is fixedly connected with the adjusting rod;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com