Connecting structure of plug-in pipe fitting

A connection structure and plug-in technology, which is applied in the direction of mechanical equipment, couplings, etc., can solve the problems that the plug-in connection method cannot be applied, and achieve the effect of simple structure, preventing loose connection of pipelines, and convenient connection assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

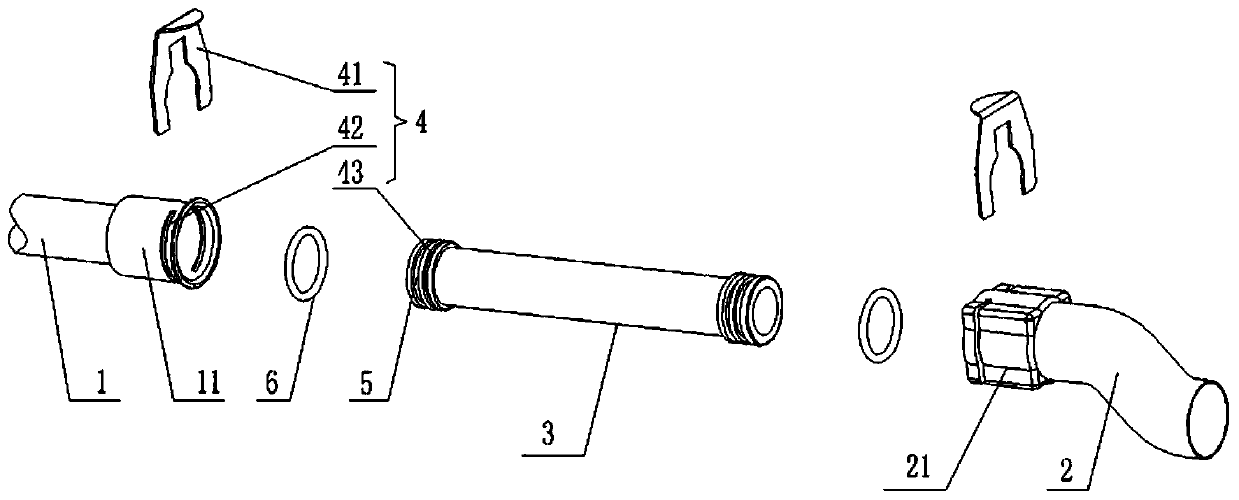

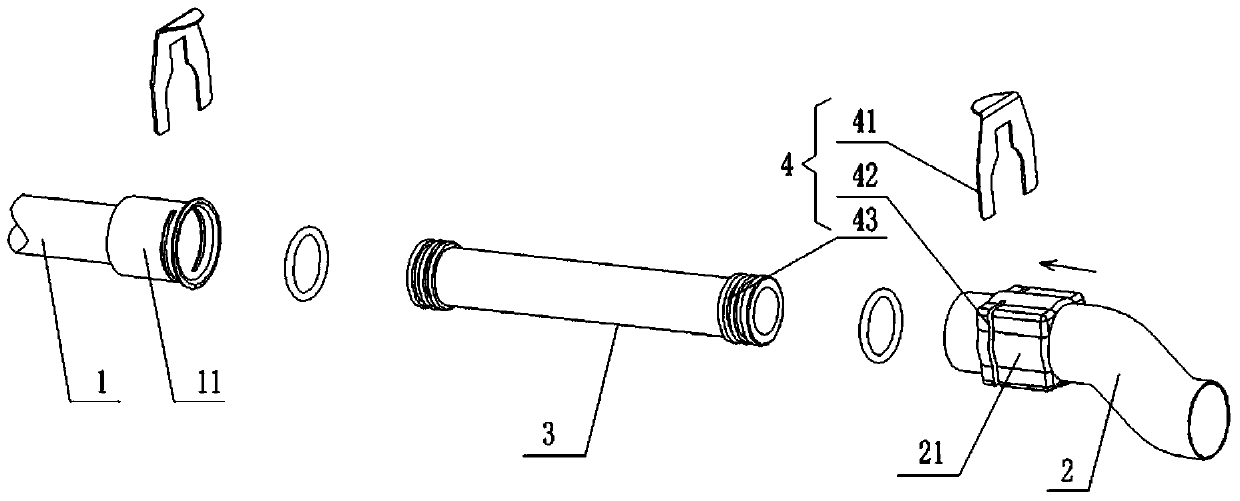

[0031] Such as figure 1 As shown, a connection structure of plug-in pipe fittings includes: end pipe 1 and end pipe 2 with fixed positions, and plug-in pipe fitting 3 connecting end pipe 1 and end pipe 2 .

[0032] Wherein, the two ends of the plug-in pipe fitting 3 are inserted on the end pipe 1 and the end pipe 2 respectively, and a movable socket with adjustable relative displacement is formed between the plug-in pipe fitting 3 and the end pipe 1 . In order to achieve position locking between the plug-in pipe fitting 3 and the end pipe 1, a buckle mechanism 4 for limiting relative displacement is also provided on the plug-in pipe fitting 3 and the end pipe 1 . In order to achieve position locking between the plug-in pipe fitting 3 and the end pipe 2, a buckle mechanism for limiting relative displacement is also provided on the plug-in pipe fitting 3 and the end pipe 2. In this embodiment, the movable socket refers to: a connector 11 is integrally formed on the end pipe 1, ...

Embodiment approach

[0033] The buckle mechanism 4 includes: an inserting plate 41 , a slot 42 penetrating through the shell wall of the connector 11 , and a slot 43 corresponding to the slot 42 provided on the plug-in pipe 3 . The inserting plate 41 is inserted into the slot 43 through the slot 42 to realize position locking between the plug-in pipe 3 and the end pipe 1 . In this embodiment, it is preferable that the slots 43 are symmetrical to each other, and there is preferably a U-shaped opening on the inserting plate 41 , and the U-shaped opening is inserted into the two left and right slots to fix the plug-in pipe 3 . In this way, the plug board 41 is very stable and reliable when plugged in. In other embodiments, the slot is only a slot, or the plug-in plate is replaced by a snap ring that extends into the connector through the slot. When the snap ring snaps into the slot, the plug-in pipe and Position locking between end tubes. As another equivalent implementation manner of the buckle me...

Embodiment 2

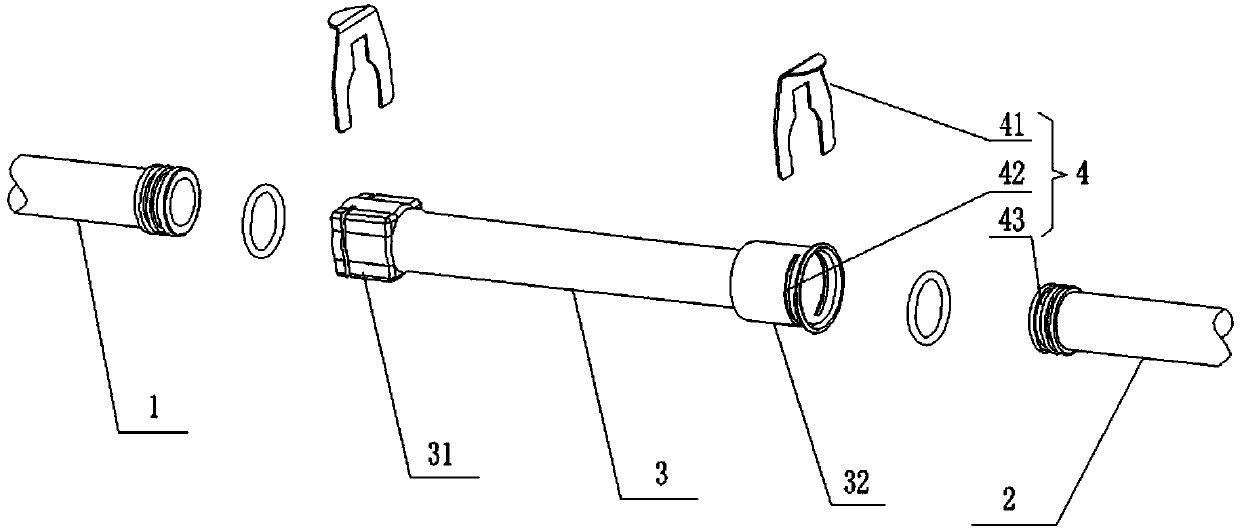

[0037] Such as figure 2 As shown, a connection structure of plug-in pipe fittings includes: end pipe 1 and end pipe 2 with fixed positions, and plug-in pipe fitting 3 connecting end pipe 1 and end pipe 2 . Wherein, the two ends of the plug-in pipe 3 are inserted on the end pipe 1 and the end pipe 2 respectively, and form a movable socket with adjustable relative displacement with at least one of the end pipe 1 and the end pipe 2 . In order to realize the position locking between the plug-in pipe 3 and the end pipe, a buckle mechanism 4 for limiting relative displacement is provided between the plug-in pipe 3 and the end pipe.

[0038] The connection structure of a plug-in pipe provided in this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0039] The flexible socket refers to: the two ends of the plug-in pipe 3 are provided with a connector 31 and a connector 32, and the end pipe 1 and the end pipe 2 are respectively inserted into the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com