Method for designing motor through numerical calculation and analytical analysis combined parameter collaborative optimization

A numerical calculation and collaborative optimization technology, applied in the electrical field, can solve the problems of not considering the magnetic field, temperature field, vibration modal situation, unable to consider the subtle distribution changes of physical parameters of structural parts, global convergence and insufficient iteration speed, etc. Achieve the effect of fast global optimization ability, improve calculation accuracy, and improve scientific rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

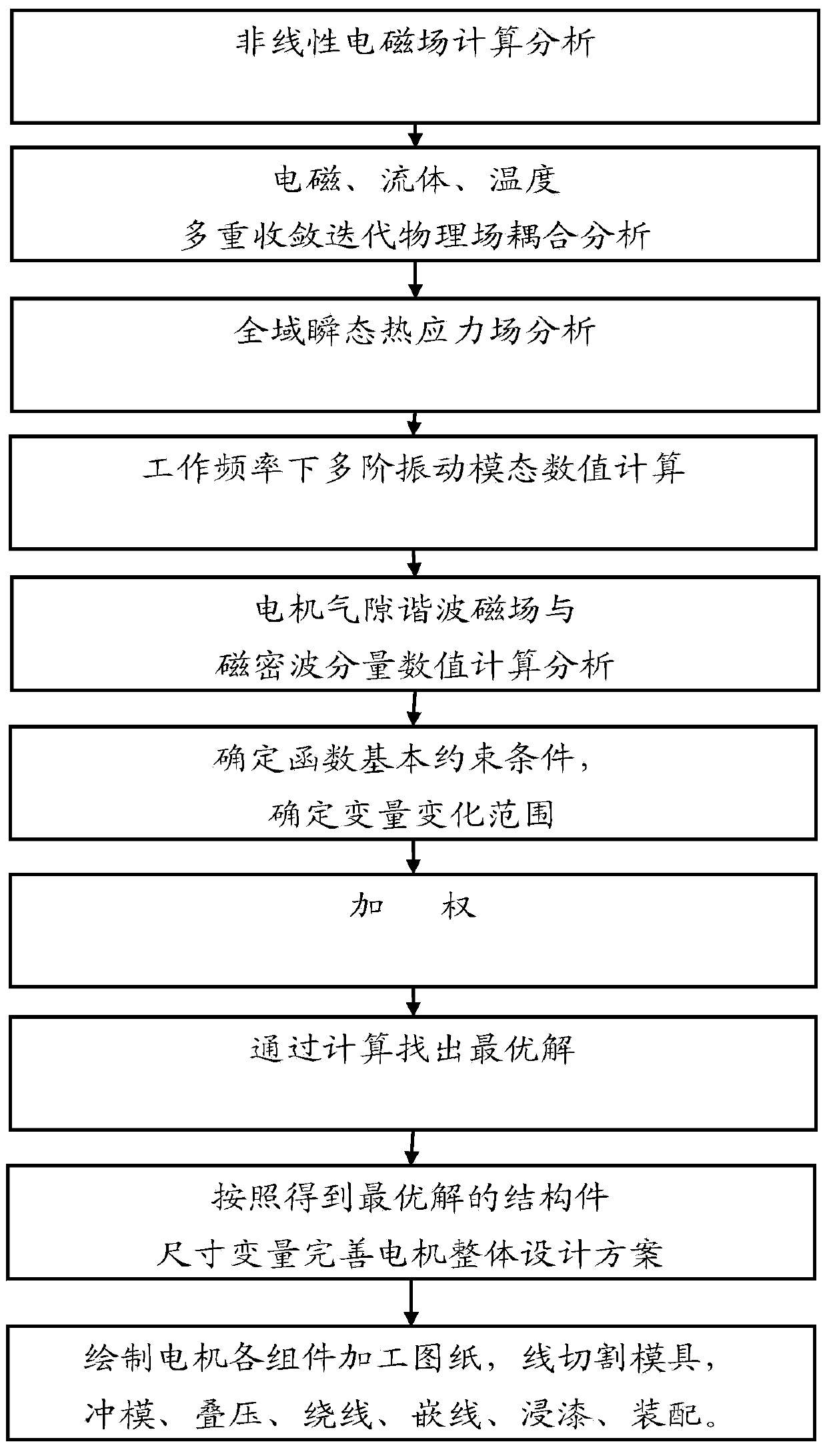

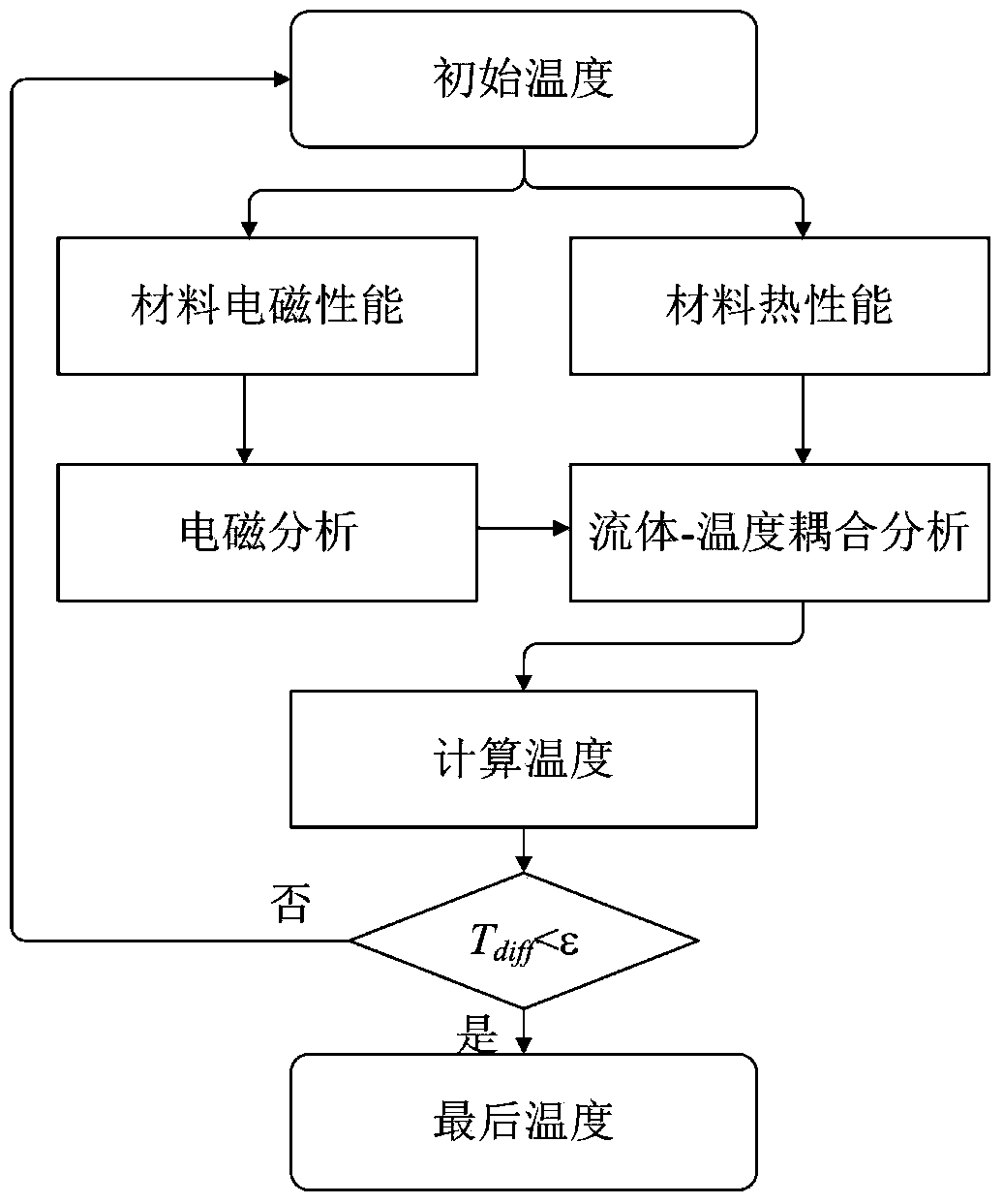

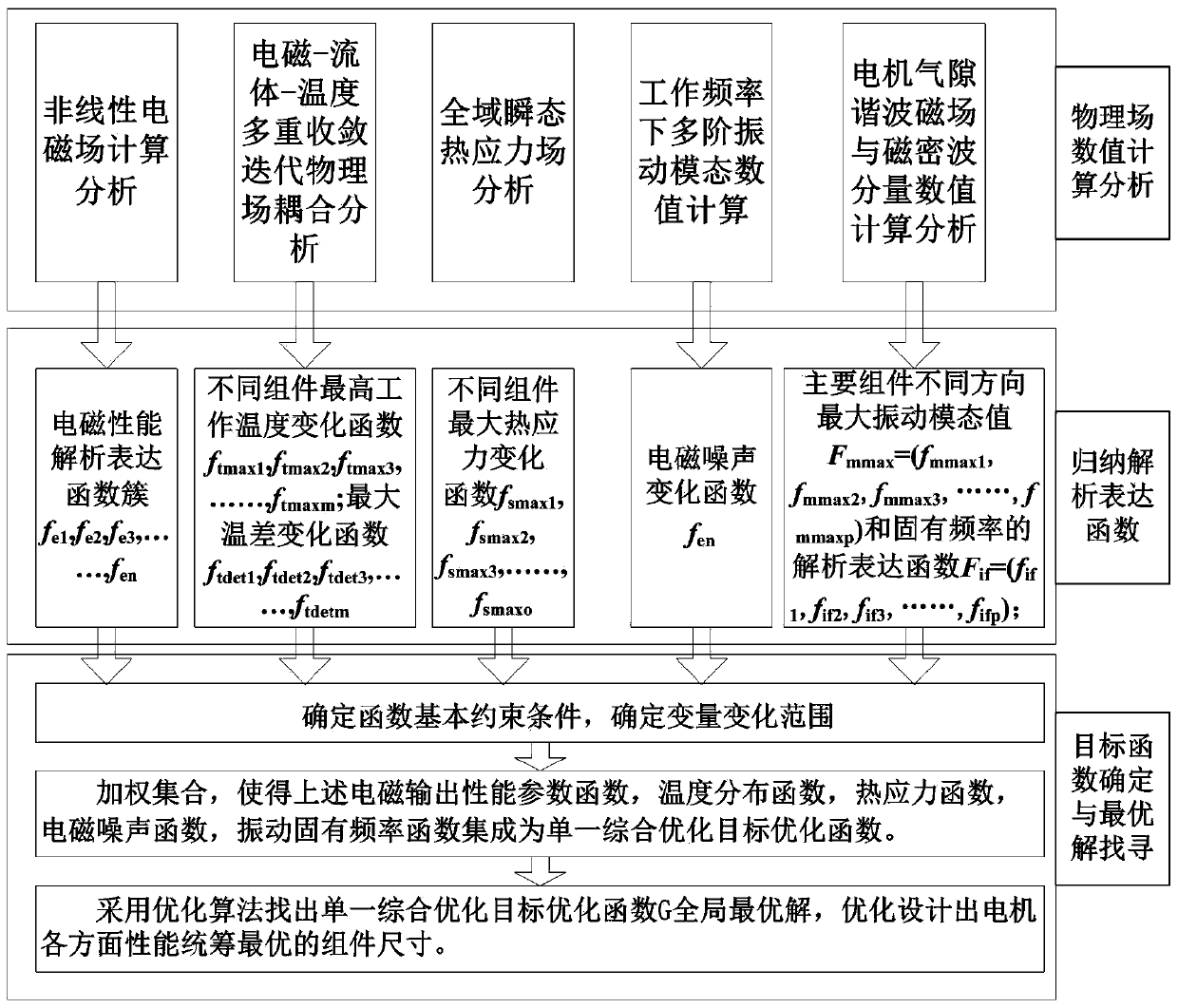

[0038] Embodiment 1: as Figure 1 to Figure 3 as shown,

[0039] Step 1) Numerical calculation of the nonlinear electromagnetic field in the motor, the distribution of the magnetic field and the electromagnetic performance parameters of the motor vary with the size of the motor structural parts, and it is concluded that the size of the structural parts X=(x 1 ,x 2 ,x 3 ,...,x k ) T Analytical Expression Function Cluster F for Electromagnetic Properties of Variables e =(f e1 , f e2 , f e3 ,..., f en );

[0040] The electromagnetic performance of the motor is different according to the design requirements, including but not limited to armature current I(X), efficiency eff(X), power factor pf(X), starting current Ist(X), starting torque Tst(X ).

[0041] F e ( X ) = f e ...

Embodiment 2

[0060] Embodiment 2: as figure 1 , figure 2 and Figure 4 As shown, the other steps are the same as in Example 1, in which step 7) the sub-objective function weighting operation adopts the unbalanced relative two-way weighting method to transform the objective function, and assigns different weighting coefficients ω according to the priority and severity of the optimization objective i ≠ω c (0<i≤j, 0<c≤j), highlighting key objects in the optimization target system;

[0061] At the same time, each value under the rated working condition is taken as the benchmark correction weighting coefficient Eliminate the influence of the numerical value of various physical performance parameters on the optimization results;

[0062] According to the requirements of performance indicators, positive weights and negative weights are used respectively for the improvement and reduction goals, and the direction of the extreme value goal of the optimization function is unified, which is norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com