A Method for Predicting the Number of Equipment Failures Based on Degradation Modeling

A technology of equipment failure and prediction method, which is applied in the direction of prediction, data processing application, calculation, etc., can solve the problems of ignoring the operation status of equipment and ignoring the actual operation status of equipment, so as to achieve good engineering application value, avoid economic loss, and save money and expenses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0049]The method for predicting the number of equipment failures based on degradation modeling of the present invention comprises the following steps:

[0050] Step 1: Establish a performance degradation model of the equipment

[0051] The degradation model based on the Wiener process is a typical linear stochastic model describing the stochastic degradation process of equipment, that is, the performance degradation rate of equipment can be approximated as a constant. According to formula (1), describe the stochastic degradation process {X(t), t≥0} based on the Wiener process;

[0052] Step 2: Estimation of parameters in the performance degradation model

[0053] According to formula (2), (3) estimated at t k The maximum likelihood values of time λ and σ;

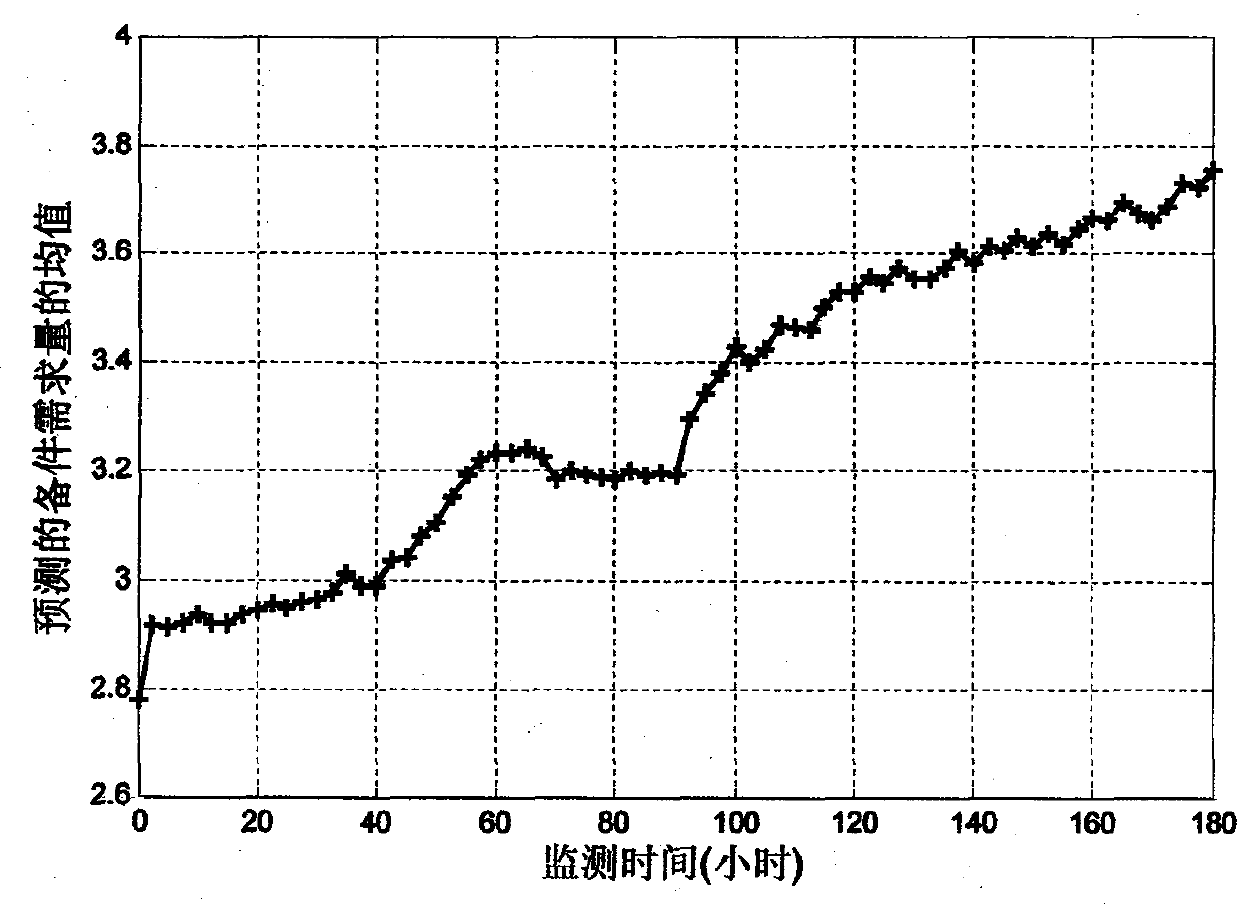

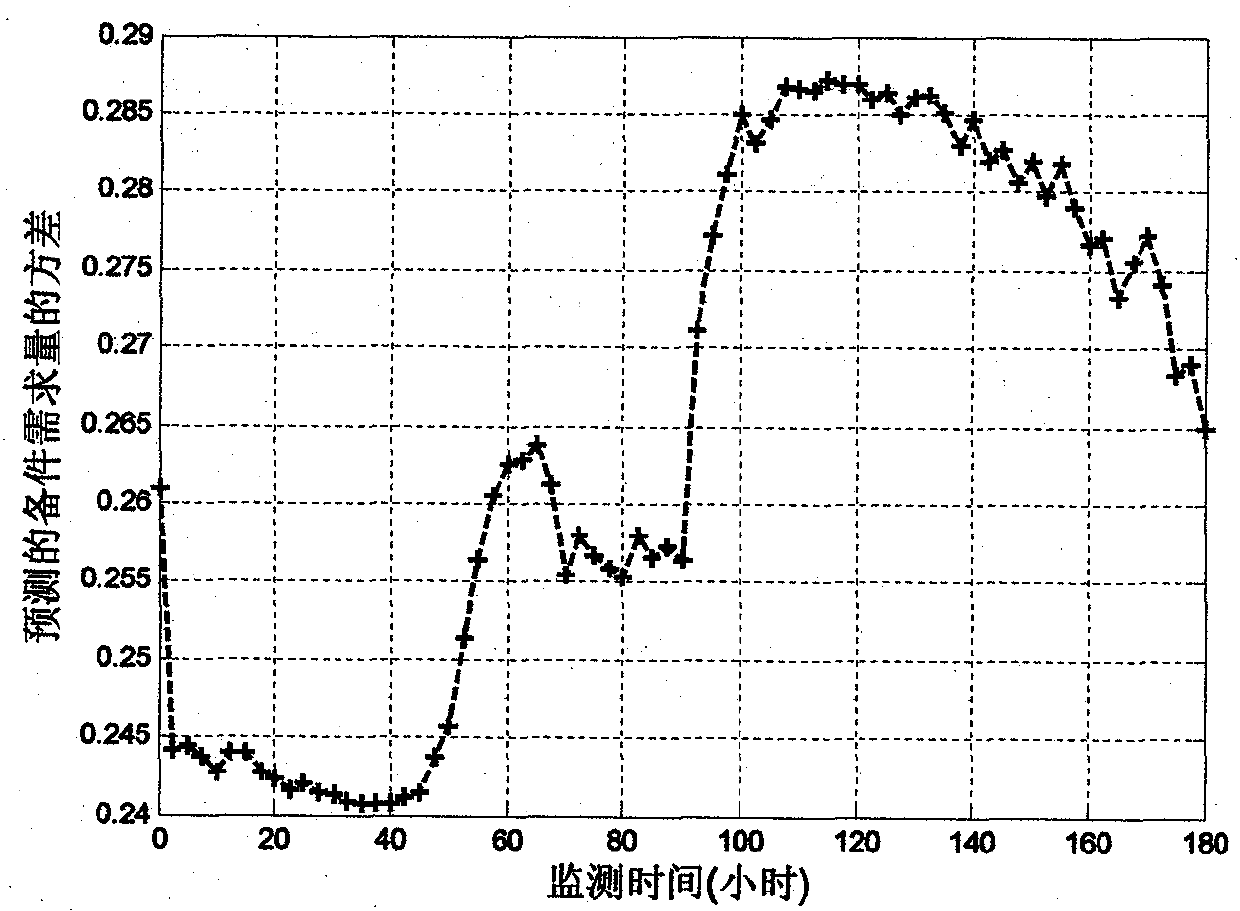

[0054] Depend on figure 2 Visible, adopt the method of the present invention, can well predict the gyroscope degradation trend;

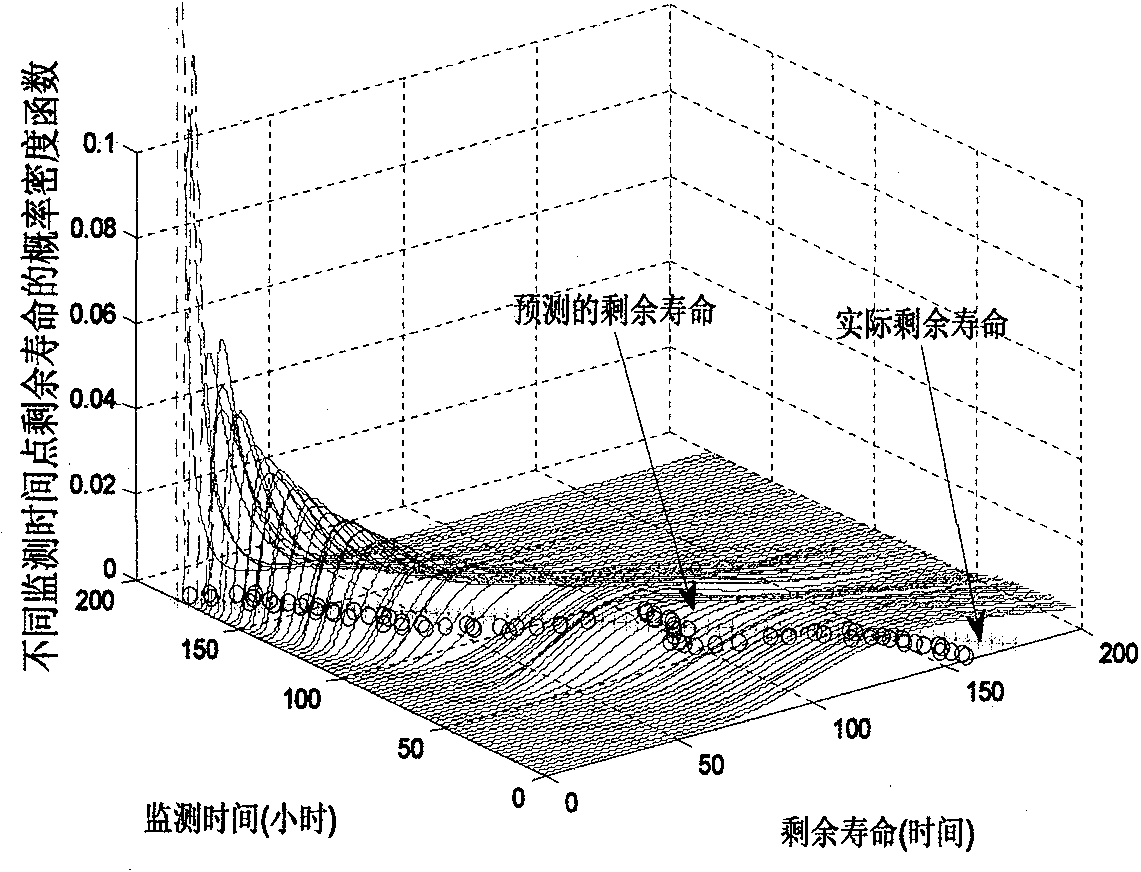

[0055] Step 3: Remaining Life Prediction

[0056] According to the formula (4) and (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com