Closed type combined trolley conductor device suitable for poor working condition

A closed, sliding contact wire technology, applied in the electrical field, can solve the problems of limited temperature resistance, limited bending radius, large physical size, etc., and achieve a good protective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

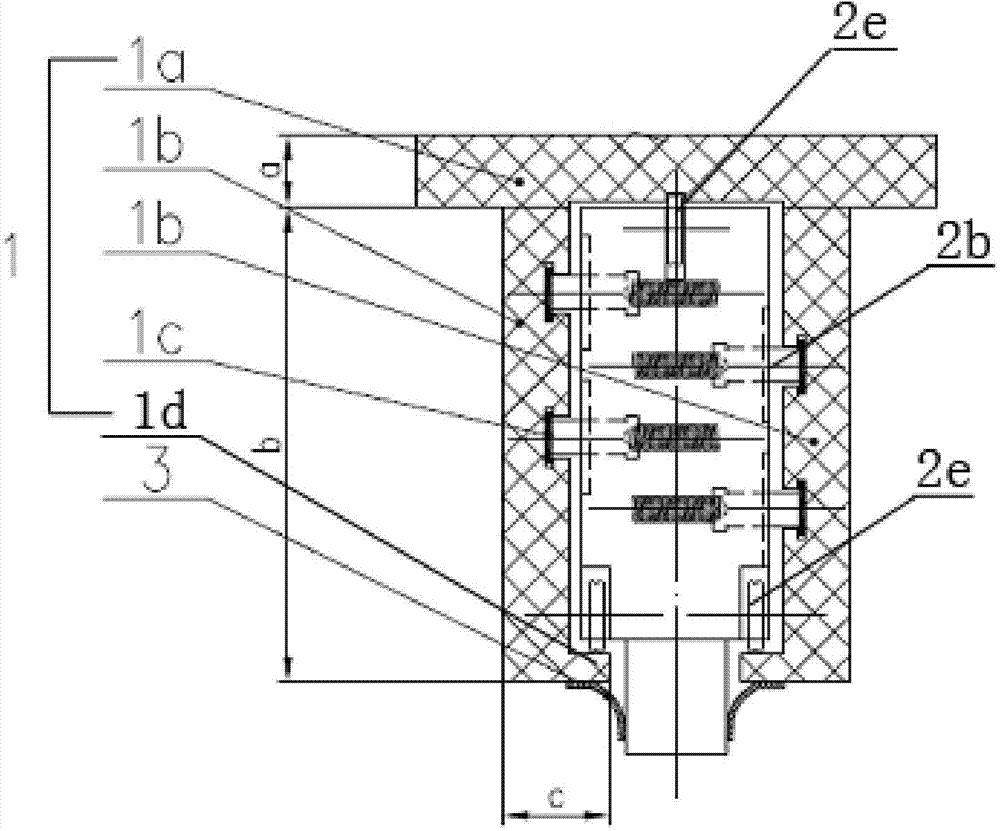

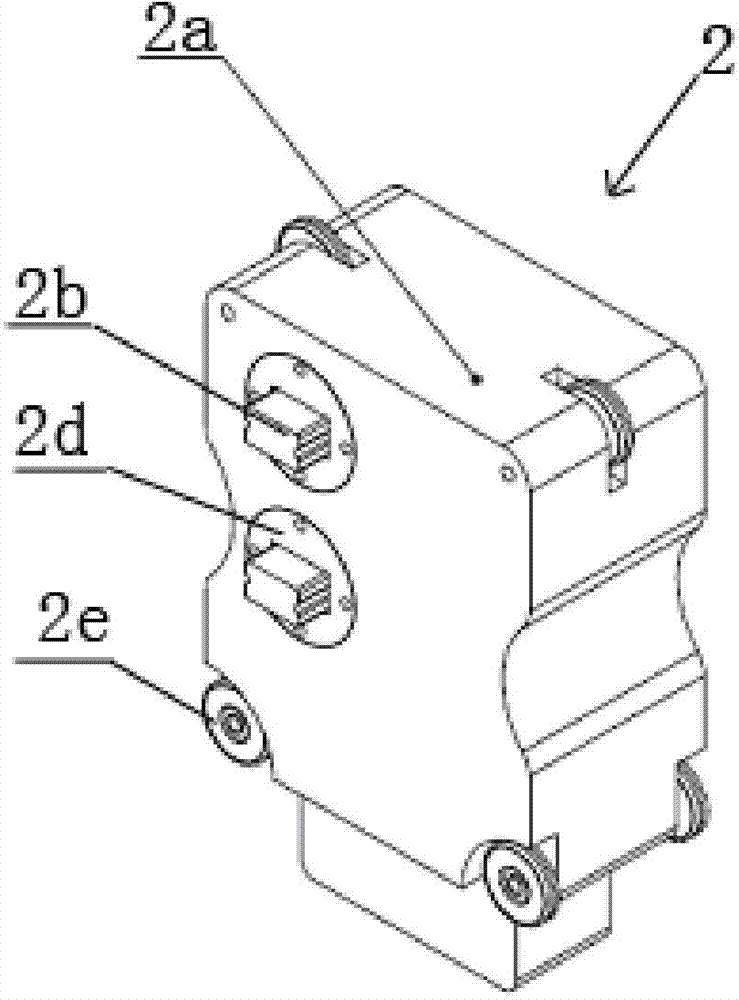

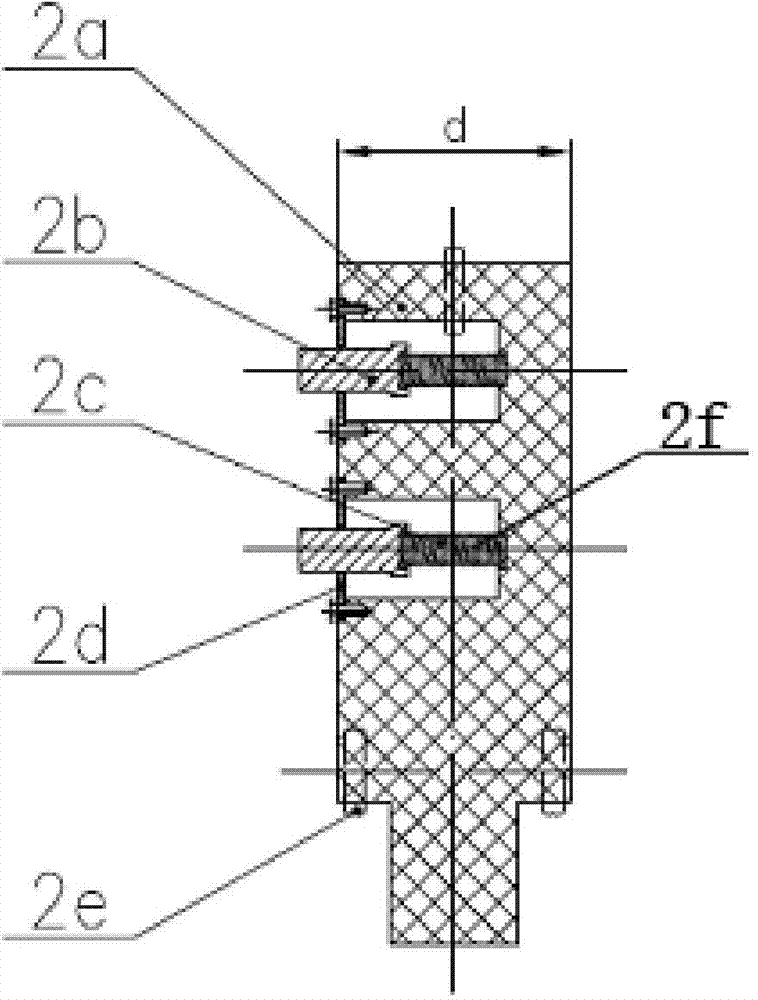

[0019] Such as Figure 1-Figure 3 As shown, the enclosed combined trolley line device suitable for harsh working conditions of the present invention includes a track 1 and a collector 2 .

[0020] A conductive strip 1c is arranged inside the track 1, and grooves are arranged inside the track 1, and a conductive strip 1c is embedded in each groove, and the conductive strip 1c is connected to a fixed power source. The conductive strip 1c may be copper strip or other conductive material. There is an opening at the lower end of the track 1, and other positions are fully enclosed. Flanges 1d for supporting the current collector 2 are provided on both sides above the opening. The opening of the track 1 is provided with two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com