Coaxial cable socket

A coaxial cable and cable technology, applied in the direction of cable joints, conductive connections, circuits, etc., can solve complex and time-consuming problems, and achieve the effect of simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

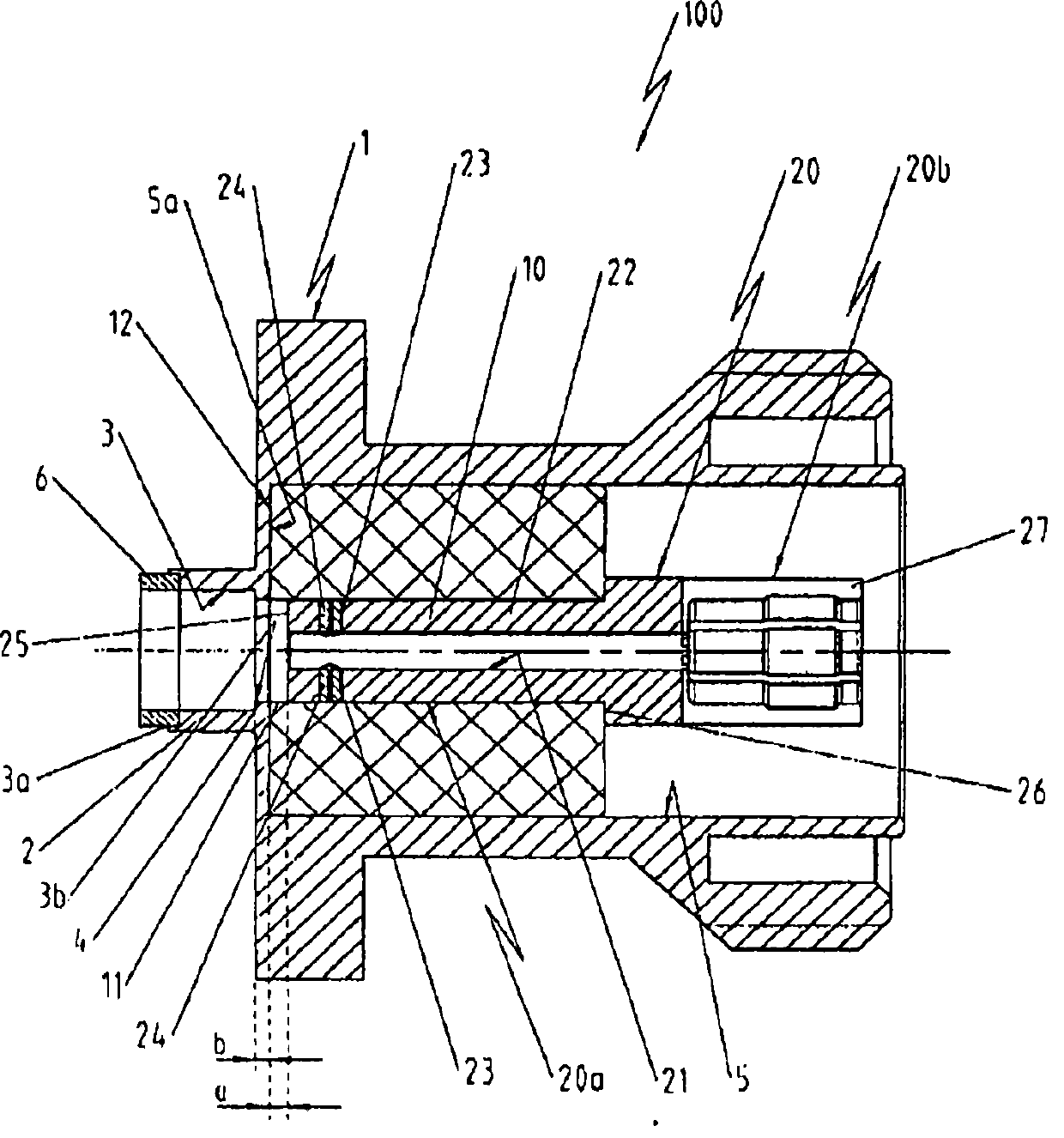

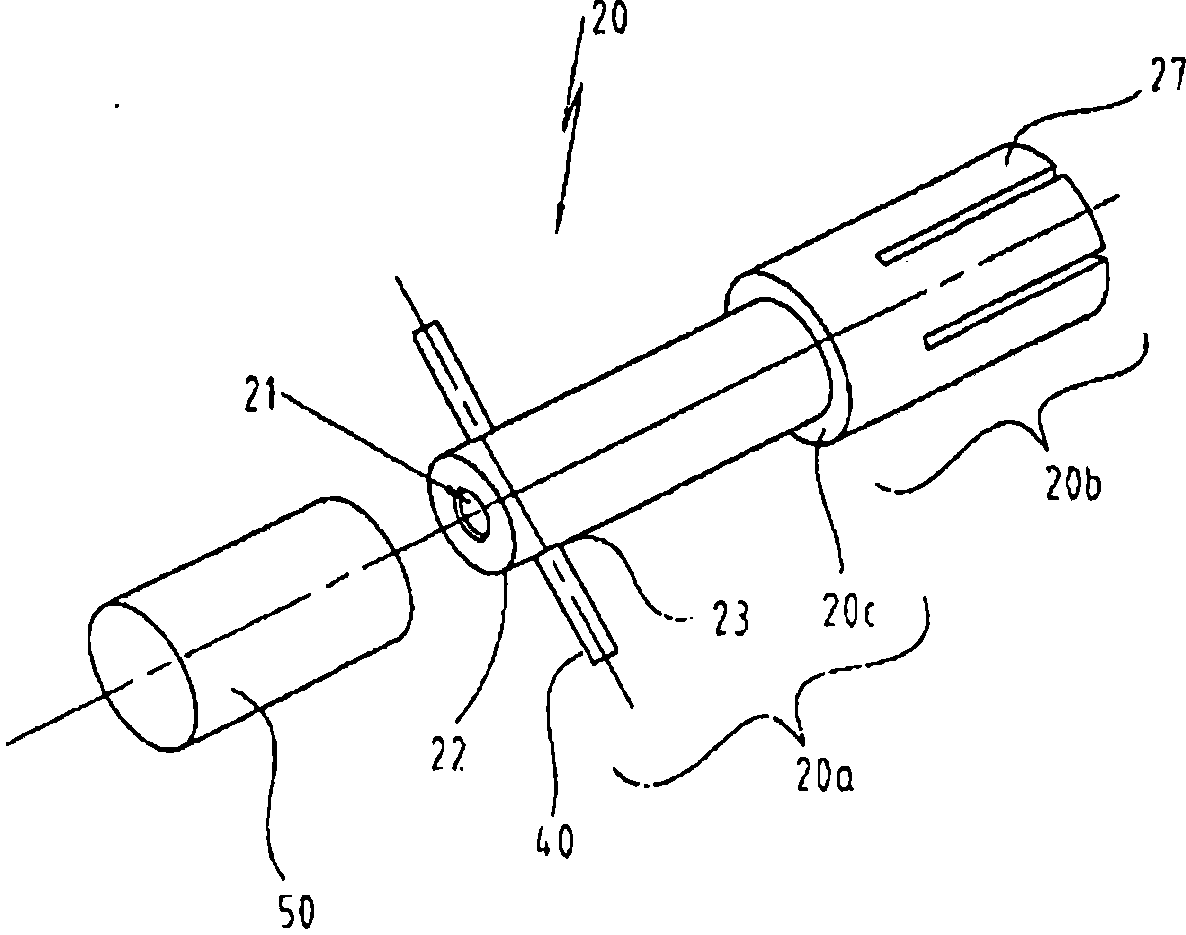

[0024] exist figure 1 The coaxial cable socket 100 shown in includes a cylindrical plug connector housing 1 in which an insulating material post 10 with a plug connector inner conductor 20 is arranged .

[0025] The plug connector housing 1 has a cable-side flange 2 with a cable-side hole 3 into which a coaxial cable (not shown) is inserted with its outer conductor and its inner conductor. . This cable-side hole 3 transitions with a smaller diameter into a through-hole 4 which opens into a plug-side hole 5 with a larger diameter. These so-called bores 3 , 4 and 5 form a continuous axially extending bore of the plug-in connector housing 1 .

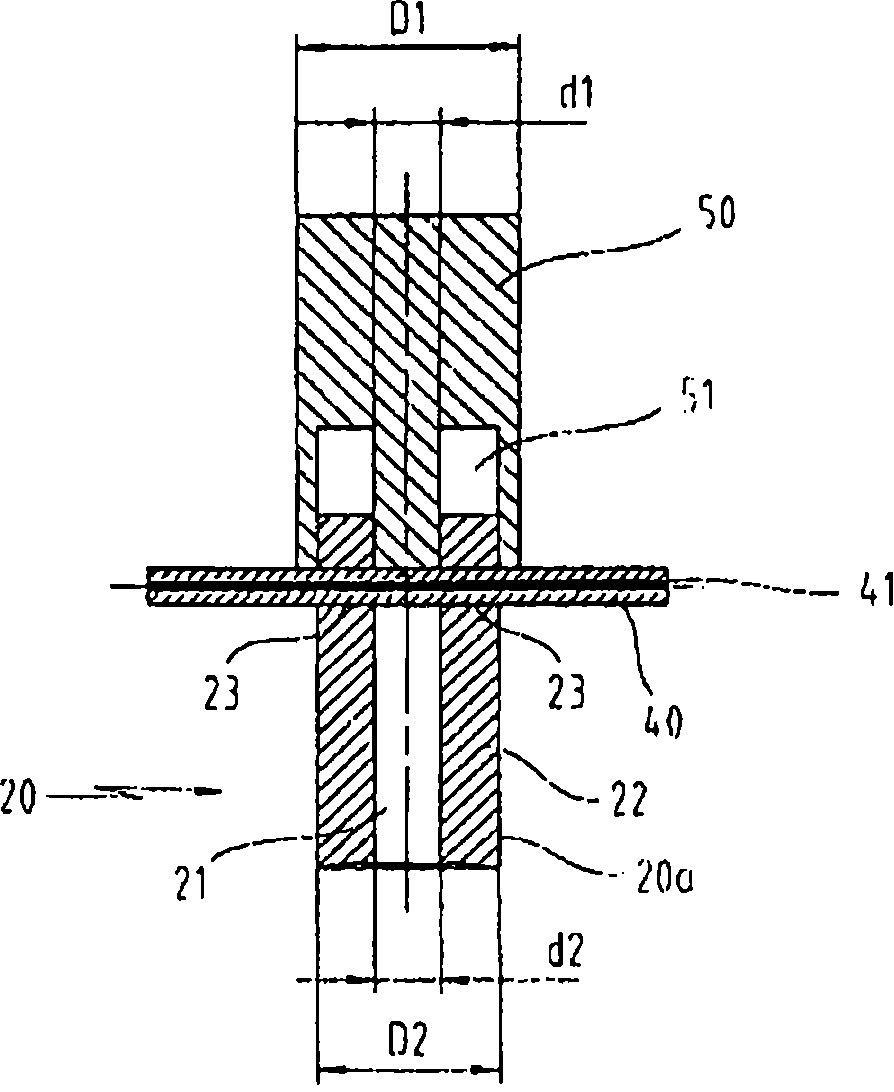

[0026] The cylindrical insulating material support 10 has a continuous inner conductor opening 11 for receiving the inner conductor 20 of the plug-in connector. This insulating material strut 10 bears against the base 5 a of the plug-side hole 5 , so that the through-opening 4 transitions continuously into the inner conductor opening 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com