An evaporative piping system humidifier

A pipeline system and humidification device technology, applied in the directions of dissolving, mixer, chemical instrument and method, can solve the problem of inability to realize humidification of pipeline equipment system, and achieve the effect of ensuring stability, reducing liquid splash and ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

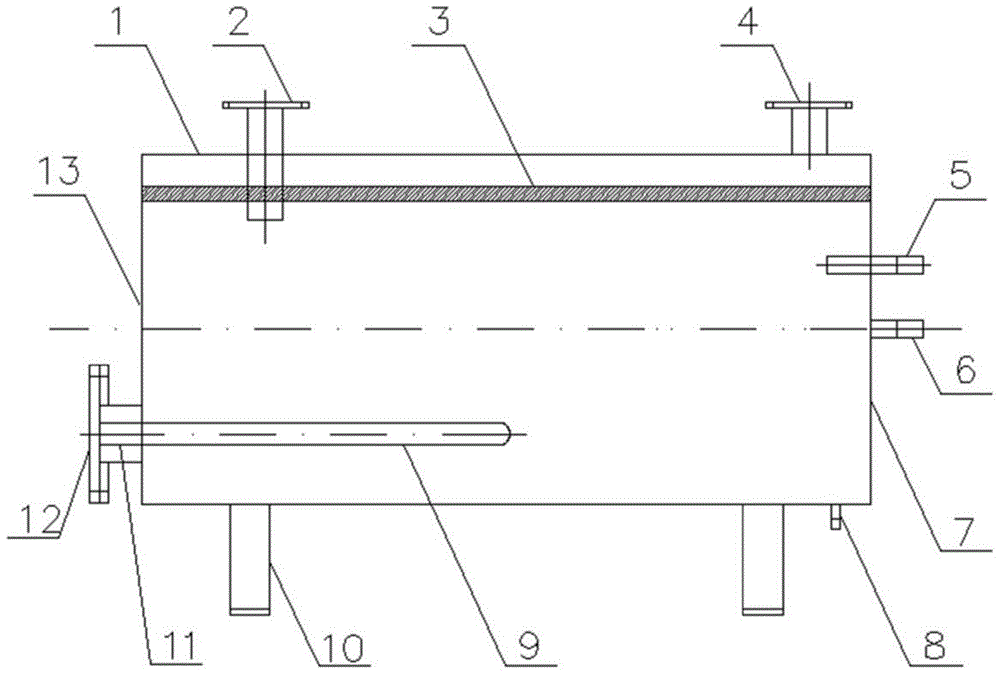

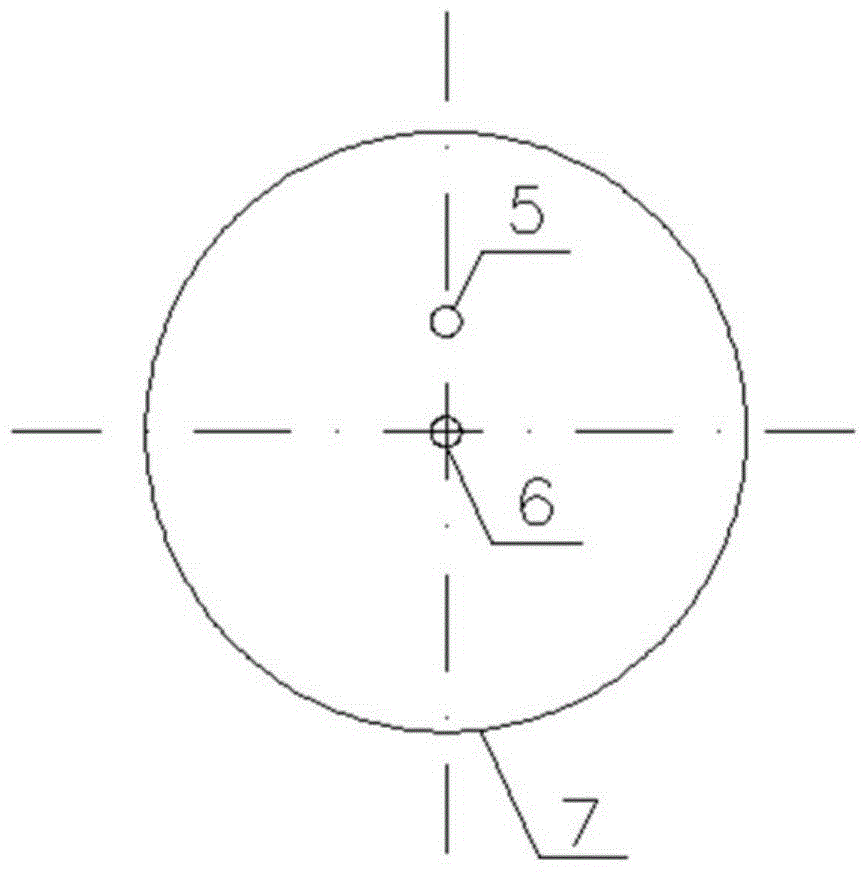

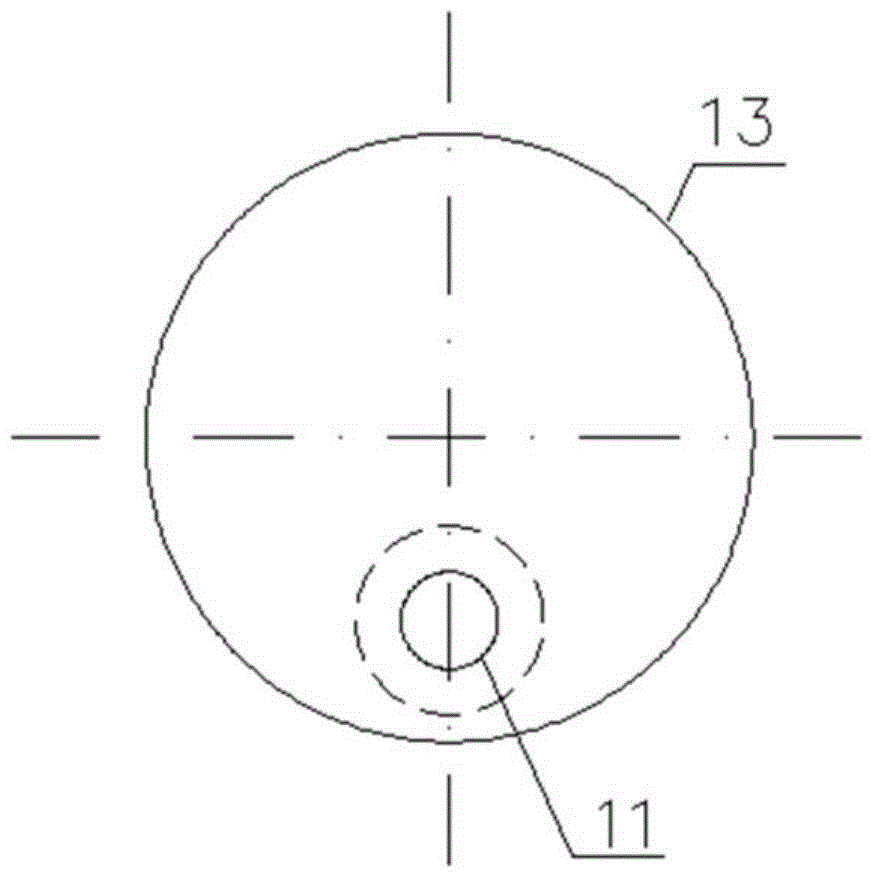

[0016] Such as figure 1 , figure 2 , image 3 As shown, the evaporative pipeline system humidifier includes: cylinder body 1, dry gas inlet pipeline 2, wet gas outlet pipeline 4, mist catcher 3, blind plate 7, water inlet pipe 5, sealing head 13, heating pipe 9, liquid bit control valve 6.

[0017] The cylinder body 1 is a stainless steel cylindrical shell, supported by a bracket 10, one end of the cylinder body 1 is closed by a head 13, and the other end is closed by a blind plate 7, and the blind plate 7 and the head 13 are welded to the cylinder body 1 Fixed connection, cylinder 1, head, and blind plate form a closed humidification system, which can realize continuous humidification of a certain pressure gas under pipeline operating conditions, and ensure continuous and stable operation of the pipeline.

[0018] The diameter of cylinder 1 is 1200mm-5000mm, the length is 2000mm-8000mm, and the wall thickness is 4mm-26mm; the diameter of head 13 is 1200mm-5000mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com