Inoculation method of nodular cast iron

A ductile iron and flow inoculation technology is applied in the inoculation of ductile iron and the preparation of ductile iron alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Inoculation in the molten iron ladle, the first inoculation in the molten iron ladle when it is released from the furnace is smelted in an intermediate frequency furnace at 1550°C, and the BaCaSi high-efficiency composite inoculant of the type J-3 is added at 0.45% of the total weight of the casting when it is released from the furnace, and placed in the molten iron ladle carry out the first pregnancy;

[0022] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand to remove slag, then cool down to a pouring temperature of 1385°C, and add BaCaSi high-efficiency composite inoculant of model J-3 to 0.25% of the total weight of the casting during pouring. second pregnancy

[0023] 3. Flowing inoculation, when pouring, use 0.05% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

Embodiment 2

[0025] 1. Inoculation in the ladle, the first inoculation in the ladle when it is released from the furnace. The intermediate frequency furnace is smelted at 1550 ° C. When it is released from the furnace, 0.65% of the total weight of the casting is added to the BaCaSi high-efficiency composite inoculant of type J-3, and it is placed in the ladle. carry out the first pregnancy;

[0026] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand still to remove slag, then cool down to a pouring temperature of 1390°C, and add BaCaSi high-efficiency composite inoculant of model J-3 to 0.35% of the total weight of the casting during pouring. second pregnancy

[0027] 3. Flowing inoculation, when pouring, use 0.1% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

Embodiment 3

[0029] 1. Inoculation in the molten iron ladle, the first inoculation in the molten iron ladle when it is released from the furnace is smelted in an intermediate frequency furnace at 1550°C, and the BaCaSi high-efficiency composite inoculant of the type J-3 is added at 0.55% of the total weight of the casting when it is released from the furnace, and it is placed in the molten iron ladle carry out the first pregnancy;

[0030] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand to remove slag, then cool down to a pouring temperature of 1380°C, and add BaCaSi high-efficiency composite inoculant of type J-3 to 0.3% of the total weight of the casting during pouring. second pregnancy

[0031] 3. Flowing inoculation, when pouring, use 0.15% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

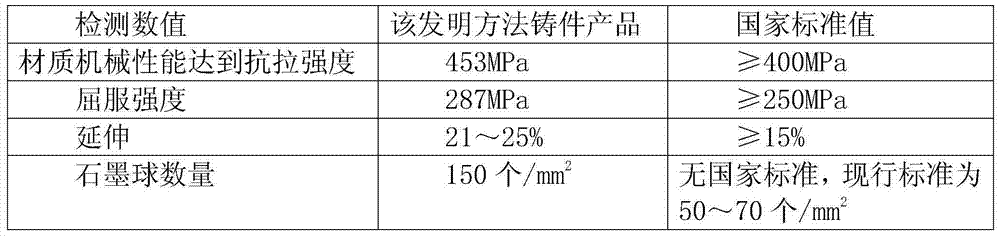

[0032] Tested by Shanghai Materials Research Institute as follows:

[0033]

[0034] It ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com