A kind of hollow brick for rapid wall-building

A hollow brick and wall-laying technology, applied in the field of hollow bricks, can solve problems such as time-consuming, time-consuming, and unstable walls, and achieve the effects of improving wall strength, improving work efficiency, and excellent sound insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

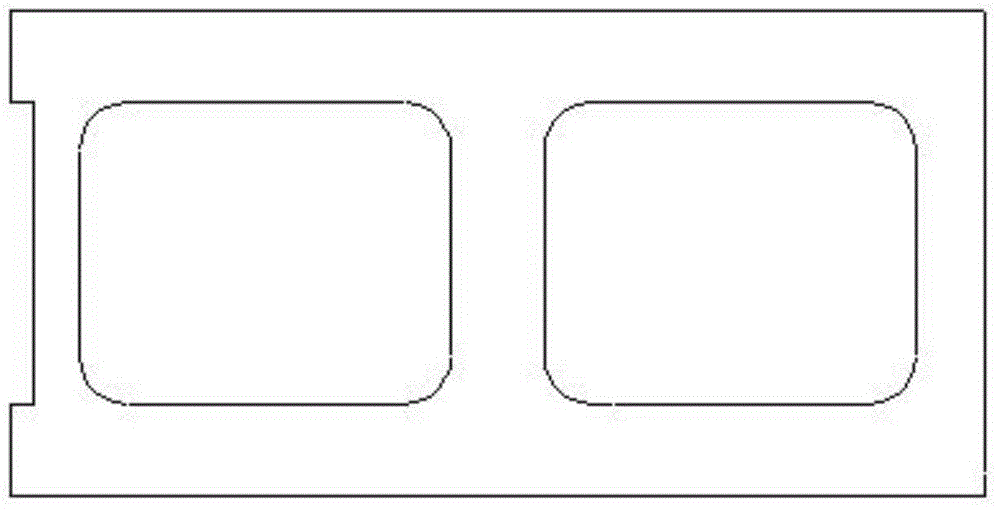

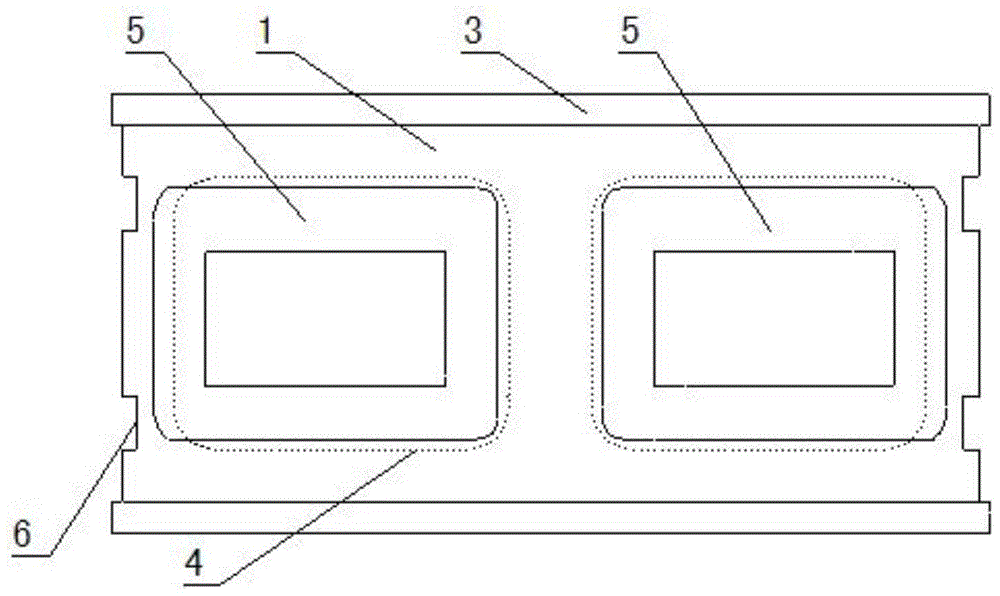

[0032] This embodiment describes a hollow brick for rapid wall-building, its structure is as follows figure 2 , image 3 As shown, a brickwork surface 4 is added on the upper plane of the hollow brick, and the hollow brick body extends into the through hole of the hollow brick to form a new brickwork surface 4, and a continuous upward The protrusion 5 is provided with a continuous upward protrusion 3 on the outer side of the upper plane 1, and a closed groove is formed between the protrusion on the newly added joint surface 4 of the upper plane 1 and the protrusion arranged on the outer side of the upper plane 1, The lower plane 2 of the hollow brick is provided with protrusions matching the groove formed by the upper plane 1 (including protrusions 8 on the front and rear sides of the lower plane and protrusions 9 on the left and right sides of the lower plane). In this embodiment, the height of the protrusions on the newly added joint surface 4 of the upper plane 1 is consi...

Embodiment 2

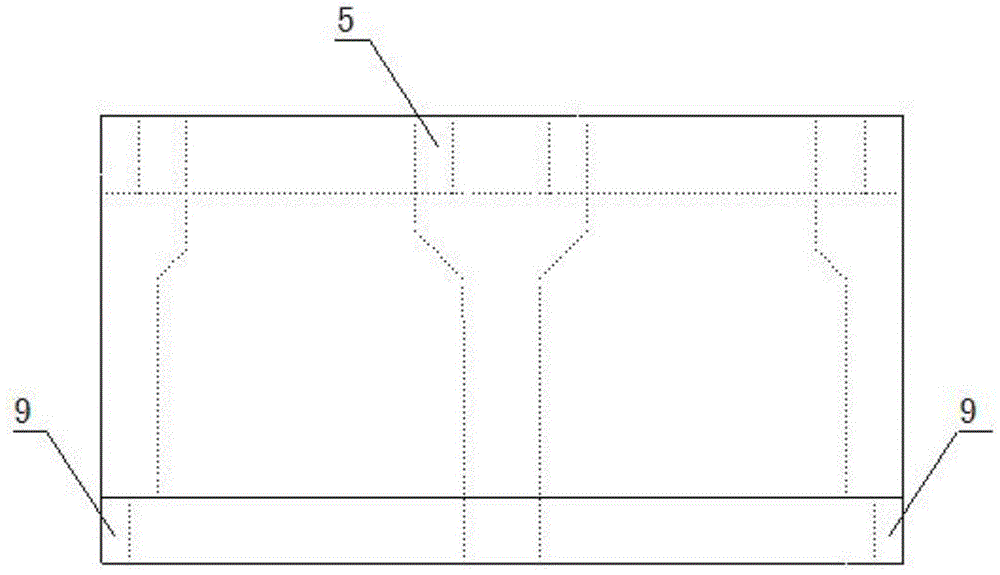

[0035] The structure of the hollow brick described in this embodiment is generally the same as that of Embodiment 1, but the upper and lower planes of the hollow brick in this embodiment are fully enclosed structures. The lower plane 2 of the hollow brick is also provided with a joint surface, and the upper and lower joint surfaces are arranged symmetrically. The structure of the hollow brick described in this embodiment is as follows: Figure 4 , Figure 5 , Image 6 shown.

[0036] A plurality of through holes are provided on the newly added joint surface 4 of the lower plane 2 of the hollow brick, and the through holes are redundant mortar overflow holes 7 for overflowing the bottom of the hollow brick. When the groove of the upper plane 1 is masonry, if less mortar is put, the mortar cannot reach the lower plane 2 of the upper block, so that the upper and lower planes cannot be bonded or the bonding effect is not good. If the mortar is put too much, the excess mortar w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com