Blind hole brick extruder

The technology of extruder and blind hole brick is applied in the field of brick making equipment, which can solve the problems of difficult molding, waste of mortar, increased energy consumption, etc., and achieve the effects of durable structure, energy saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A more specific description will be made below in conjunction with the accompanying drawings.

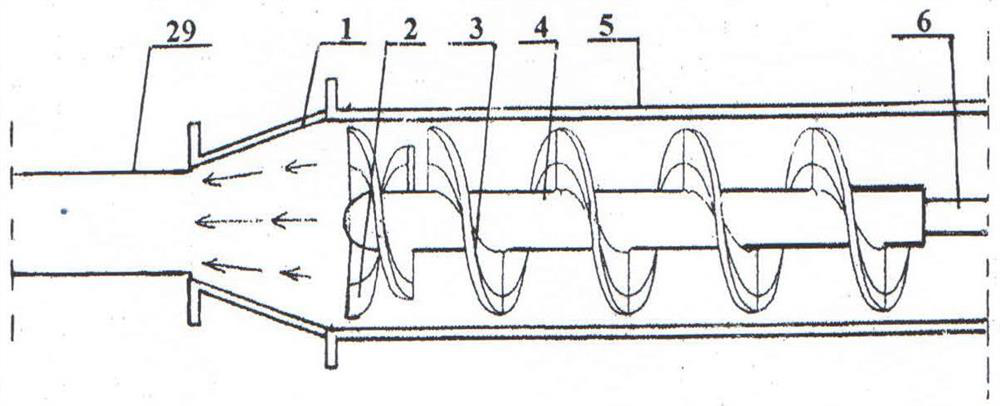

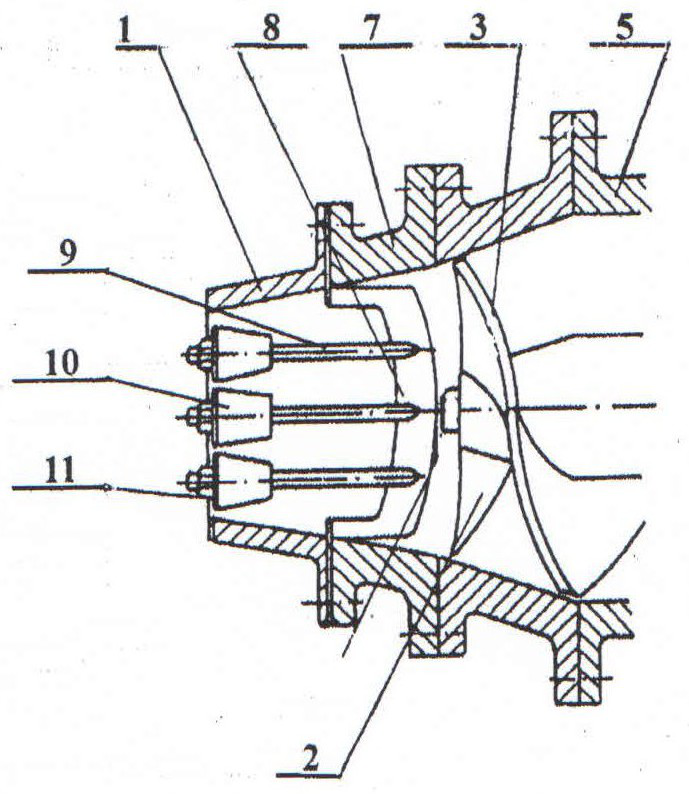

[0019] figure 1 with figure 2 It has been described in more detail in the above-mentioned "background technology";

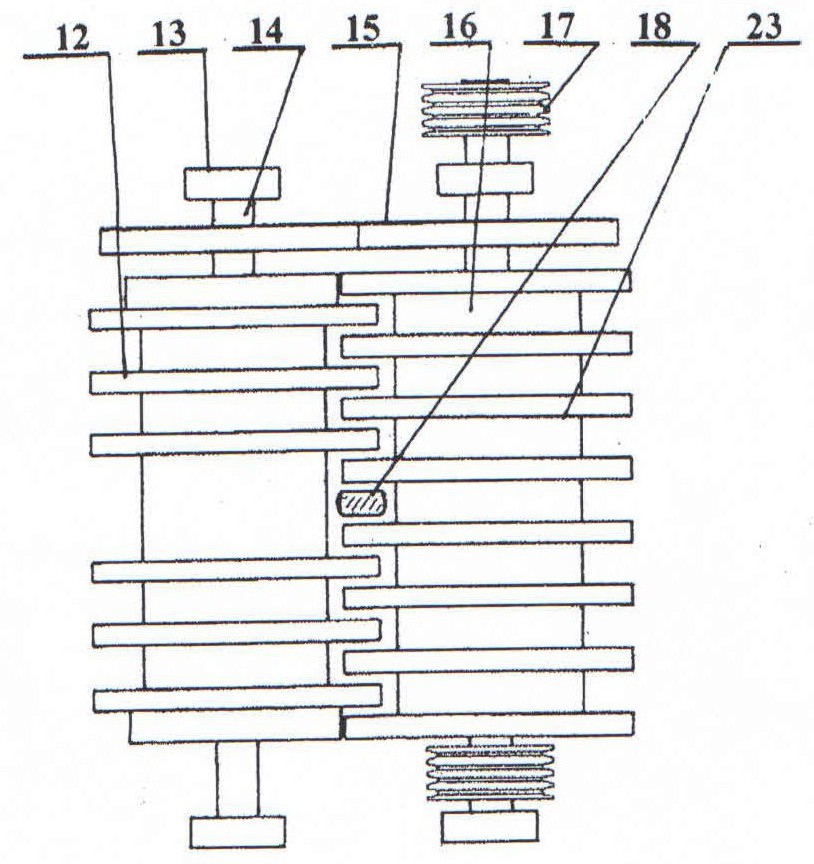

[0020] refer to Figure 3 to Figure 5 , two cylinders 23 whose outer peripheral lines are a plurality of annular grooves (concave) grooves and annular convex strips are arranged in a flat manner with each other, and the width dimension of the concave groove 16 is greater than the width dimension of the convex strip 12, and the annular concave grooves and annular convex strips are formed with each other. The convex lines are fitted together but not close to each other. The center of each drum is a transmission shaft 14, and its two ends are supported and positioned by bearing seats 13 containing bearings. The two ends of the transmission shaft 14 or one of the ends are sleeved with transmission wheels 17. The inner edge of the drum 23, that is, the left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com