Long-service-life piston head

A piston head and long-life technology, which is applied in the direction of liquid variable displacement machinery, variable displacement pump components, machines/engines, etc., can solve the problems of inconvenient installation and disassembly, short service life, etc., to reduce the failure rate and make up for Abrasion, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

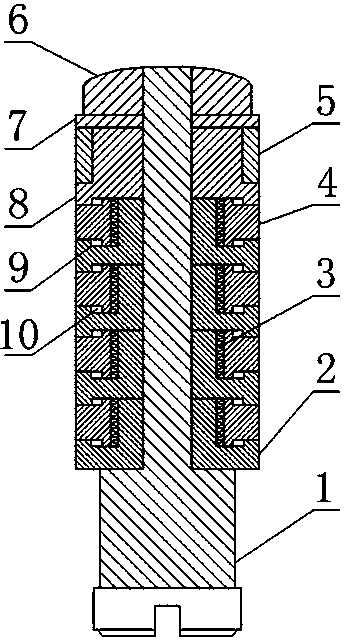

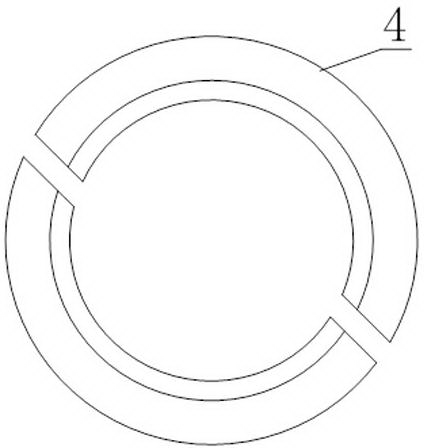

[0023] like figure 1 , figure 2 and image 3 , a long-life piston head, including a mandrel 1 and a piston ring 4, and also includes a locking end cap 6, an elastic ring 3 and a plurality of piston ring retaining rings 2 each provided with a central hole, the mandrel 1 being one end A stepped shaft with an external thread is provided, and the piston ring retaining rings 2 are sequentially installed on the mandrel, and a ring-shaped piston ring installation groove 9 perpendicular to the axis of the mandrel 1 is formed between two adjacent piston ring retaining rings 2 , each piston ring mounting groove 9 is provided with an elastic ring 3, and each elastic ring 3 is provided with a piston ring 4, and a gap is provided on the piston ring 4, and the locking end cap 6 and the mandrel The external thread section of 1 becomes threaded connection.

[0024] Specifically, the arranged piston ring 4 is in contact with the inner wall of the cylinder to form a sealing surface to form ...

Embodiment 2

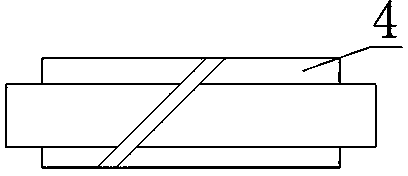

[0026] This embodiment is further improved on the basis of embodiment 1, as figure 1 , figure 2 and image 3 , the cross-section of the piston ring mounting groove 9 is T-shaped, and its inner width is greater than the outer width, and the cross-section of the piston ring 4 is also T-shaped with an inner width greater than the outer width. There is also a sliding gap 10 with a width in the range of 2 mm-5 mm between the inner and outer ends of 9 .

[0027] The setting of the shape of the piston ring 4 and the piston ring mounting groove 9 is convenient for increasing the compressive stress on the inner wall of the cylinder on the outside of the piston ring 4 by increasing the force-bearing area inside the piston ring 4, even if the height is greater than that of the outside of the piston ring 4. Elastic ring 3, so that under the condition of ensuring the sealing performance of piston ring 4, it is convenient to choose elastic ring 3 that is easy to deform, which not only fa...

Embodiment 3

[0030] This embodiment is further improved on the basis of embodiment 1, as figure 1 , figure 2 and image 3 , also includes a disc-shaped guide ring seat 8 and a guide ring 5 fixed on the mandrel 1, and an annular groove is arranged on the outer side of the guide ring seat 8, and the guide ring 5 is located in the groove. The set guide ring 5 is used to guide the movement track of the mandrel 1 relative to the cylinder, which is conducive to uniform force on the circumferential direction of the piston ring 4 and prolongs the service life of the piston ring 4 .

[0031]In order to facilitate the installation of the guide ring 5 on the mandrel 1, the guide ring seat 8 is provided with a central hole, the guide ring seat 8 is installed on the mandrel 1, and the groove is connected with the end surface of the guide ring seat 8. The above setting also facilitates setting a piston ring 4 between the guide ring seat 8 and the piston ring retaining ring 2 close to it, so that it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com